Nickel-zinc nanometer battery

A nano-battery technology, applied in the direction of nickel storage battery, battery electrode, nanotechnology, etc., can solve the problems of short battery life, low cycle life, easy deformation, etc., and achieve the effect of large energy ratio, good stability and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

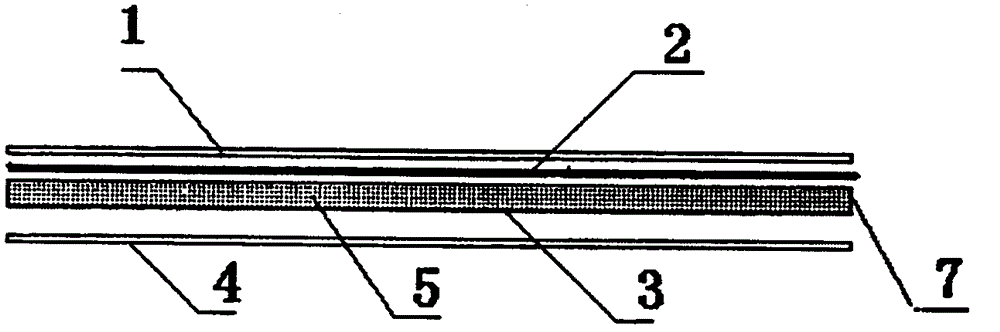

[0017] Such as figure 1 Shown, a kind of nickel-zinc nano-battery, it comprises at least: the lithium battery shell that contains cobalt nickel-plated steel strip, positive electrode 1, separator 2, negative electrode 4, separator 2 is between positive electrode 1 and negative electrode 4, separator 2 There is a combination 7 of nano-carbon and nickel mesh between the negative electrode 4; the combination 7 of nano-carbon and nickel mesh is coated with nano-carbon 3 on the surface of the nickel mesh 5; the thickness of the nickel mesh is 5um. The lithium battery casing of the cobalt-containing nickel-plated steel strip of the lithium-ion battery is based on SPCE, and the two sides of the substrate are respectively coated with a nickel-cobalt binary alloy film; the nickel-cobalt binary alloy film is a grain size 50-100nm nanocrystalline coating with a thickness of 2μm; the middle layer is a Ni / Co / Fe diffusion layer with a thickness of 1μm produced after diffusion heat treatment...

Embodiment 2

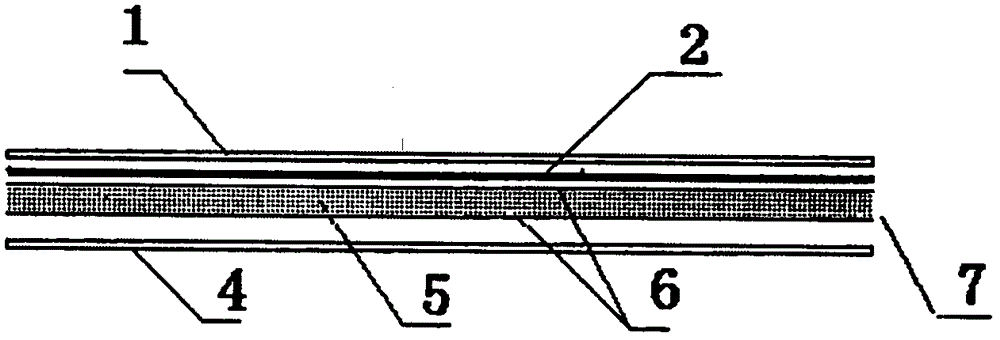

[0019] Such as figure 2 Shown, a kind of nickel-zinc nano-battery, it comprises at least: the lithium battery shell that contains cobalt nickel-plated steel strip, positive electrode 1, separator 2, negative electrode 4, separator 2 is between positive electrode 1 and negative electrode 4, separator 2 There is an assembly 7 of nano-carbon and nickel mesh between the negative electrode 4; the assembly 7 of nano-carbon and nickel mesh is attached to the upper and lower surfaces of the nickel mesh with the nano-carbon film 6, and the thickness of the nickel mesh is 9um. The specific method is:

[0020] 1) The carbon material in the super Ni-Zn-C (nickel-zinc-carbon) battery is only responsible for drawing current and does not participate in the reaction. Research experiments have shown that the diaphragm has a significant impact on the capacity and life of the battery; zinc ions can be reversibly intercalated and deintercalated in carbon materials, so superimposing ultra-thin p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com