Isolation blanket for ecological restoration of metal waste storage yard

An ecological restoration and metal technology, applied in the direction of solid waste removal, application, and restoration of polluted soil, etc., can solve the problems of environmental pollution and ecological deterioration of metal ore solid waste yards, and achieve the reduction of the release of toxic heavy metals, The effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

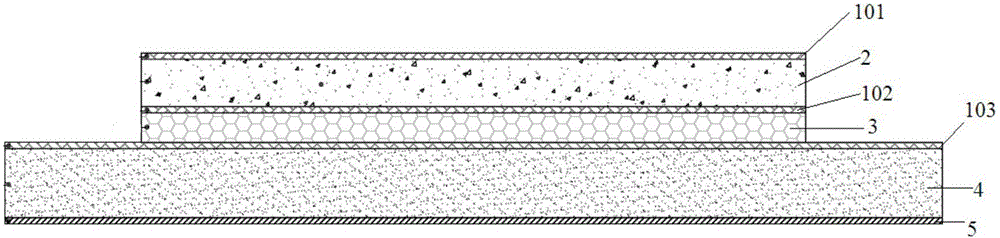

[0026] Such as figure 1 As shown, an isolation blanket for the ecological restoration of waste metal yards provided by the embodiment of the present invention includes a low-permeability layer, a water-conducting layer, and a growth matrix layer arranged in sequence from bottom to top, and the growth matrix layer includes two upper and lower layers. The needle-punched staple fiber non-woven fabric 101, the needle-punched staple-fiber non-woven fabric 102 and the lightweight matrix 2 arranged between the needle-punched staple-fiber non-woven fabric 101 and the needle-punched staple-fiber non-woven fabric 102 are stacked. The substrate 2 is fermented from one or more of crop stalks, crop husks and wood processing waste, and the lightweight substrate 2 is evenly spread on the lower needle-punched staple fiber non-woven fabric 102. In this embodiment Among them, the crop husk is peanut or rice, etc., and the wood processing waste is sawdust or wood shavings, etc., and the mass den...

Embodiment 2

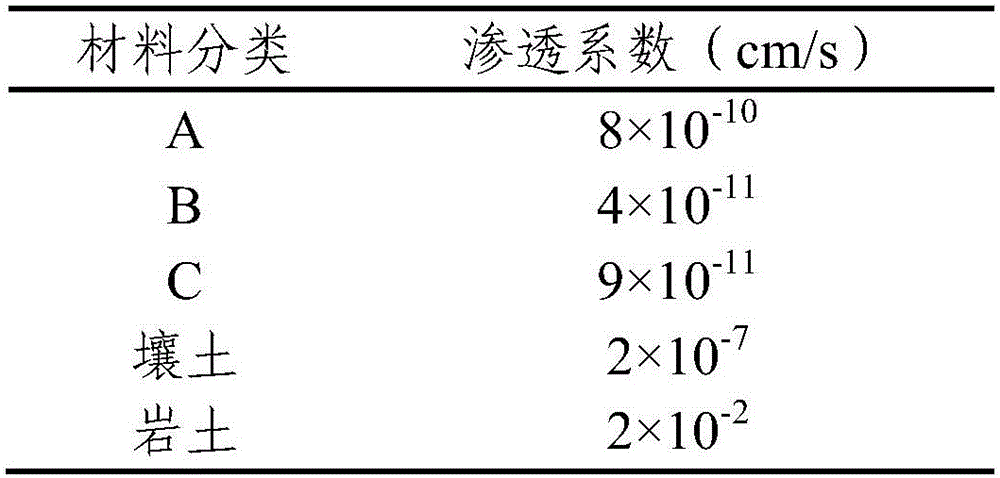

[0045] Embodiment 2 of the present invention is similar to Embodiment 1, and the same parts will not be repeated. The difference between the two is that the specification of the PP woven fabric is 200g / m 2 , Needle-punched staple fiber non-woven fabric 101, needle-punched staple-fiber non-woven fabric 102 and needle-punched staple-fiber non-woven fabric 103 are all 150g / m 2 ; The mass density of powdery sodium bentonite 4 in the low permeability layer is 4000g / m 2 , the particle size of powdery sodium-based bentonite 4 is 200 mesh; the thickness of the three-dimensional geonet 3 in the aquifer is 6mm: the mass density of light matrix 2 is 8000g / m 2 ; The light substrate 2 is the fermented crop straw. According to the above specifications, the isolation blanket B was prepared by the method of Example 1.

Embodiment 3

[0047] Embodiment 3 of the present invention is similar to Embodiment 1 and Embodiment 2, and the same parts will not be repeated. The difference is that the specification of PP woven fabric 5 is 200g / m 2 , Needle-punched staple fiber non-woven fabric 101, needle-punched staple-fiber non-woven fabric 102 and needle-punched staple-fiber non-woven fabric 103 are all 200g / m 2 ; The mass density of powdery sodium bentonite 4 in the low permeability layer is 3000g / m 2 , the particle size of powdery sodium bentonite 4 is 200 mesh; the thickness of three-dimensional geonet 3 in the aquifer is 6mm; the mass density of light matrix 2 is 6000g / m 2 ; The light substrate 2 is the fermented crop straw. According to the above specifications, the isolation blanket C was prepared by the method of Example 1.

[0048] Analyze the permeability coefficient of the insulation blanket in above-mentioned three embodiments

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com