Method for preparing transformable robot through composition of shape memory alloy and liquid metal

A technology of liquid metal and memory alloy, which is applied in metal material coating technology, manipulators, manufacturing tools, etc., can solve problems such as liquid metal objects or machines that have not yet been prepared, and achieve the effect of laser irradiation repair and strong photothermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

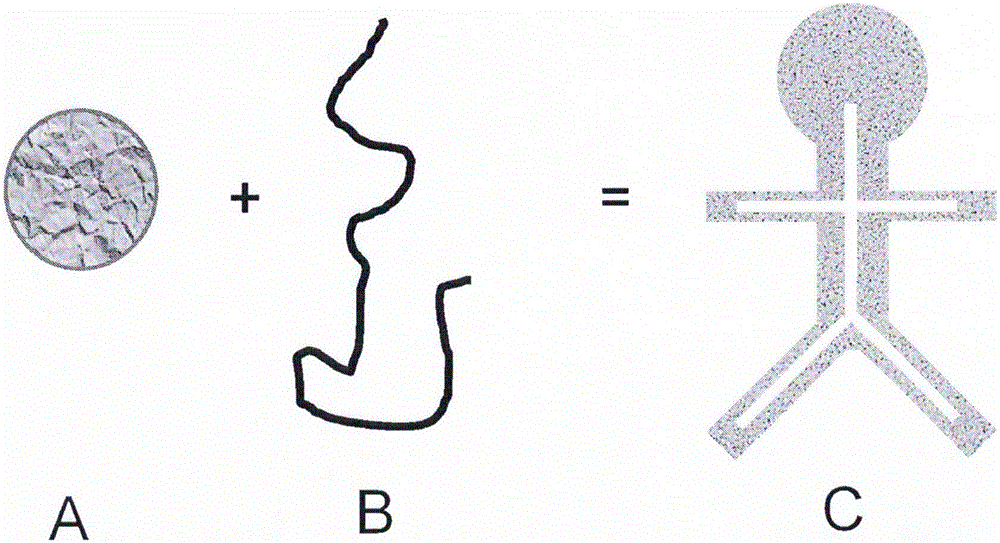

[0026] The invention provides a method for preparing a deformable robot with a shape memory alloy composite liquid metal, the preparation method comprising:

[0027] a. Mix 70g of gallium, 20g of indium, and 10g of tin in a ratio of 7:2:1 to form a liquid metal with a melting point of 50°C;

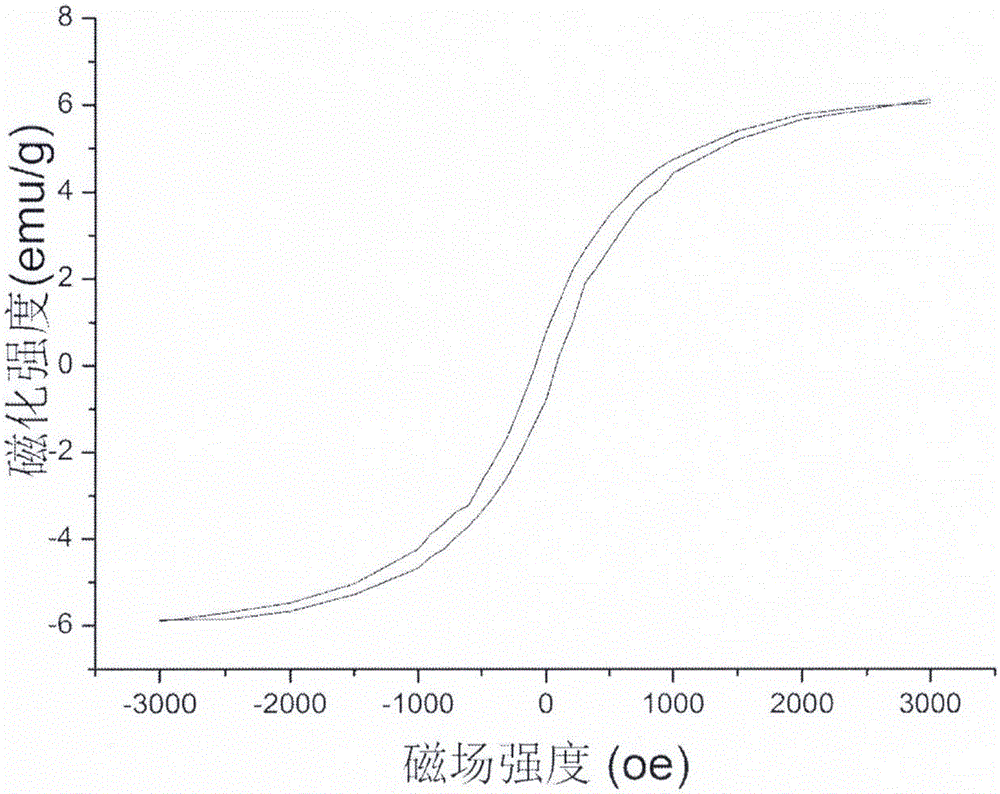

[0028] b, adding 10g Fe and 1g phosphorene composite magnetic nanoparticles in the liquid metal described in step a, the weight percentage of magnetic ions and phosphorene is 10:1, then the magnetic particles are processed by CO2 plasma sputtering, the power is 200W, the gas pressure is 100Pa, the sputtering time is 30min, and a magnetic liquid metal solution is obtained;

[0029] c. The NiTi shape memory alloy is pre-deformed into human form at 500°C for 3 hours, and the surface of the NiTi shape memory alloy is treated with H2 plasma;

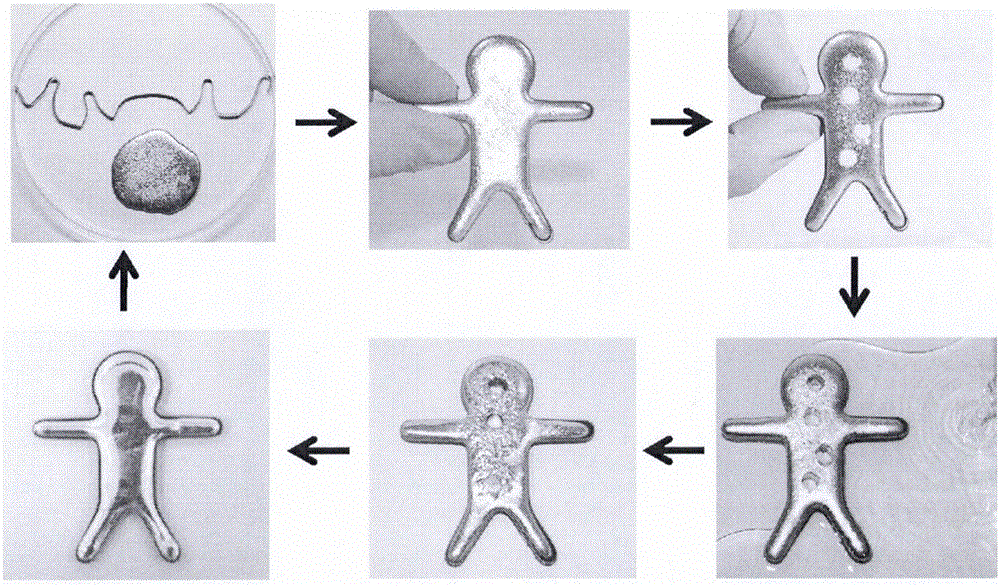

[0030] d. Composite liquid metal and shape memory alloy, and use electric field drive in 70°C water to obtain the shape memory alloy composite liquid m...

Embodiment 2

[0034] The invention provides a method for preparing a deformable robot with a shape memory alloy composite liquid metal, the preparation method comprising:

[0035] a. Mix 50g of gallium, 40g of indium, and 10g of tin in a ratio of 5:4:1 to form a liquid metal with a melting point of 60°C;

[0036] B, in the liquid metal described in step a, add the magnetic nanoparticle that 10g Ni is combined with 1g phosphorene, the weight percentage of magnetic ion and phosphorene is 10: 1, then magnetic particle is through CO2 plasma sputtering process, power is 200W, the gas pressure is 200Pa, and the sputtering time is 60min to obtain a magnetic liquid metal solution;

[0037] c. The NiTi shape memory alloy is pre-deformed into human form at 600°C for 3 hours, and the surface of the NiTi shape memory alloy is treated with Ar plasma;

[0038] d. Composite the liquid metal and the shape memory alloy, and drive the shape memory alloy composite liquid metal in water at 80° C. to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com