Method for dephosphorization of electroplating wastewater

A technology for electroplating wastewater and water conservancy, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Reasonable structure, improving the efficiency of wastewater treatment and social, improving the effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples further illustrate this application

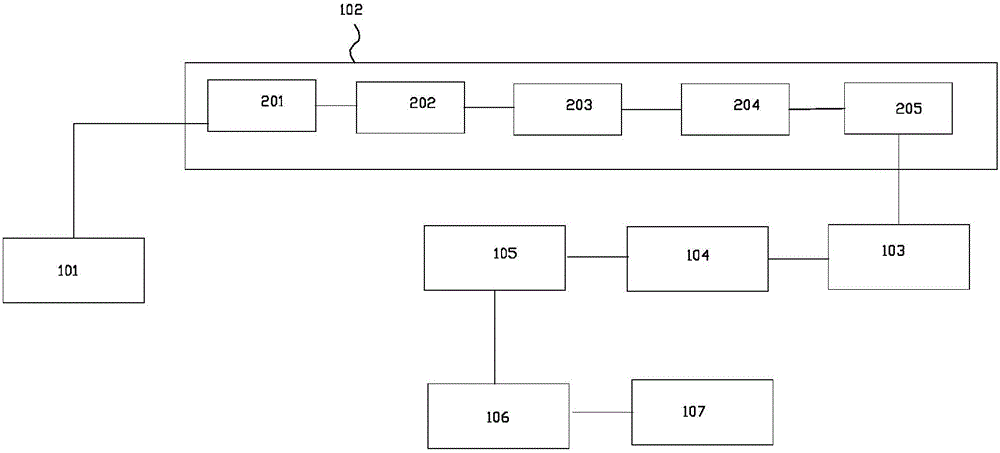

[0028] An embodiment of the present invention is a method for removing phosphorus from electroplating wastewater (the electroplating wastewater treatment system is such as figure 1 Shown), including the following steps:

[0029] The electroplating wastewater is passed through the hydrolysis acidification tank 101, the activated sludge system 102, the inclined tube sedimentation tank 103, the ozone sedimentation tank 104, the aerated biological tank 105, the Fenton coagulation tank 106 and the chemical sedimentation tank 107 in order to meet the discharge standards.

[0030] Specifically:

[0031] The electroplating wastewater contains about 20 mg / L of phosphorus before entering the hydrolysis acidification tank.

[0032] Hydrolysis acidification tank:

[0033] The hydrolysis acidification tank uses polyethylene fillers to increase the contact area between the waste water and the fillers. Some inorganic particles and sus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com