A kind of furyl glycidyl ether and its synthesis method and application

A technology of glycidyl ether and synthesis method, applied in the direction of organic chemistry, etc., can solve problems such as easy cracks, brittleness, and large internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

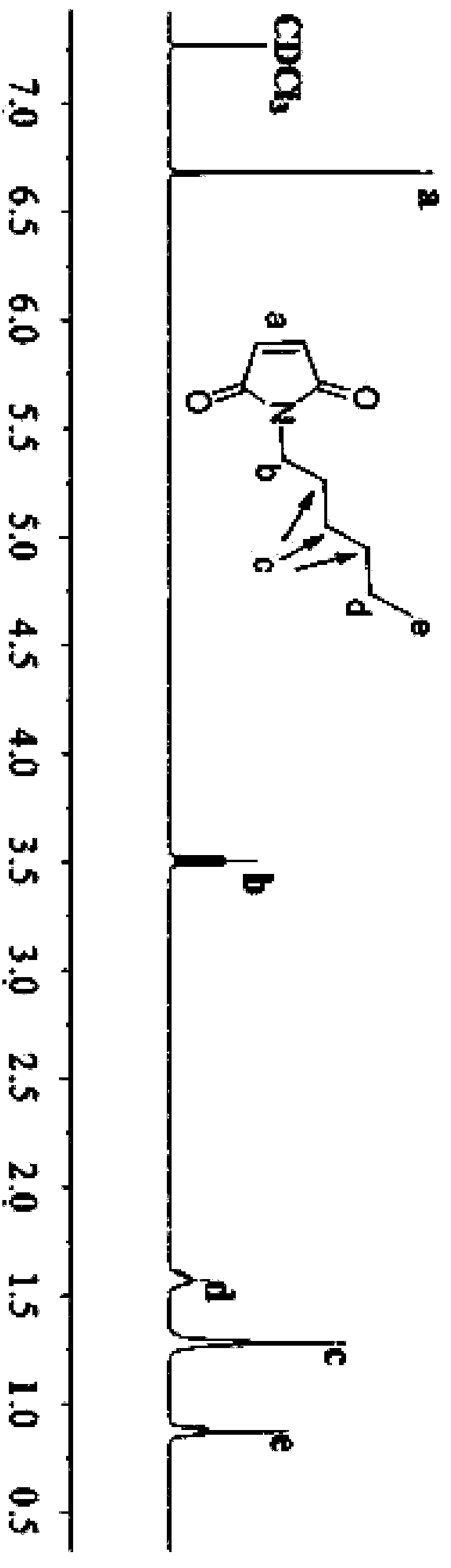

[0049] (1) Mix 100g of maleic anhydride, 1000g of dichloromethane, and 100g of n-hexylamine evenly, react at 30°C for 8 hours, add 150g of oxalyl chloride dropwise to the reaction solution, react at 30°C for 168 hours, and finally in the reaction solution 150g of triethylamine was added dropwise, reacted at 30°C for 24 hours, extracted three times with dichloromethane, washed with saturated brine three times, dried, and dichloromethane was distilled off under reduced pressure to obtain N-hexylmaleimide;

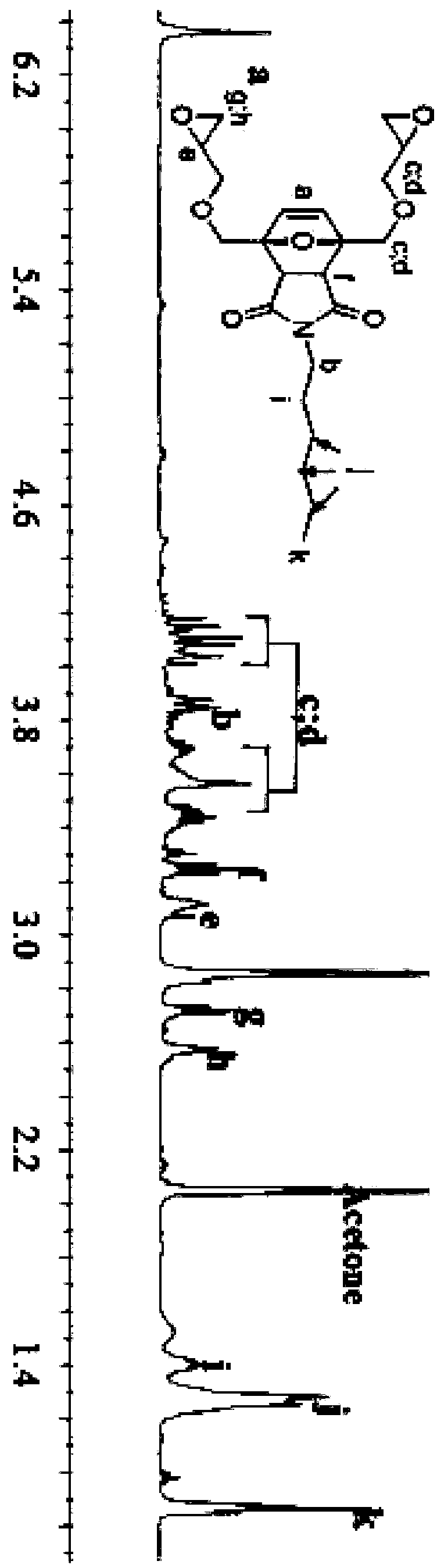

[0050] The proton nuclear magnetic resonance spectrum of the N-hexylmaleimide that prepares is as figure 2 shown;

[0051] (2) 100g N-hexylmaleimide, 500g chloroform and 150g furandimethanol glycidyl ether were reacted at 30°C for 24 hours, and the chloroform was removed by distillation under reduced pressure to obtain the formula (I) The furyl glycidyl ether shown, wherein the R group is n-hexyl.

[0052] The yield of the product was 70%, and the epoxy value of the product ...

Embodiment 2

[0055] (1) Mix 100g maleic anhydride, 1000g dichloromethane, and 100g n-hexylamine evenly, react at 40°C for 6 hours, add 200g of oxalyl chloride dropwise to the reaction solution, react at 40°C for 120 hours, and finally in the reaction solution 200g of triethylamine was added dropwise, reacted at 40°C for 24 hours, extracted three times with dichloromethane, washed with saturated brine three times, dried, and dichloromethane was distilled off under reduced pressure to obtain N-hexylmaleimide;

[0056] (2) 100g N-hexylmaleimide, 500g chloroform and 150g furandimethanol glycidyl ether were reacted at 30°C for 24 hours, and the chloroform was removed by distillation under reduced pressure to obtain the formula (I) The furyl glycidyl ether shown, wherein the R group is n-hexyl.

[0057] The yield of the product was 58%, and the epoxy value of the product was 0.46 (theoretical epoxy value was 0.475).

Embodiment 3

[0059] (1) Mix 100g maleic anhydride, 700g acetone, and 150g n-decylamine evenly, react at 40°C for 8 hours, add 100g of acetyl chloride dropwise to the reaction solution, react at 40°C for 240 hours, and finally drop in the reaction solution Add 150g of acetic anhydride, react at 40°C for 50 hours, obtain N-decylmaleimide after extraction, washing with water, drying, and distillation under reduced pressure to remove the solvent;

[0060] (2) 100g N-decylmaleimide, 300g ethyl acetate and 100g furandimethanol glycidyl ether were reacted at 50°C for 24 hours, and the ethyl acetate was distilled off under reduced pressure to obtain formula (I) Shown furyl glycidyl ether, wherein the R group is n-decyl.

[0061] The yield of the product was 55%, and the epoxy value of the product was 0.41 (theoretical epoxy value was 0.419).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com