Polyimide preparation method

A technology of polyimide and polyimide film, which is applied in the field of polyimide preparation, can solve the problems of unstable material quality, cumbersome operation, and high environmental protection pressure, shorten the production cycle, facilitate recycling, less toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

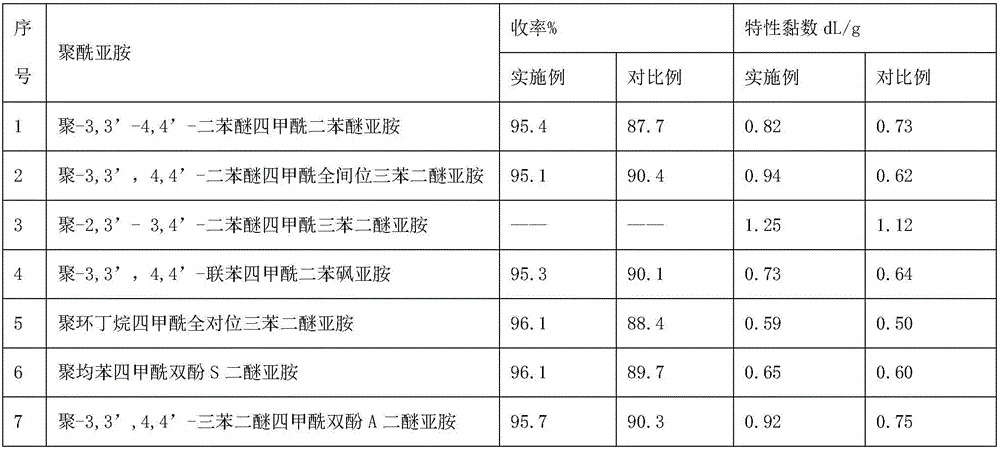

Examples

Embodiment 1

[0033] Take 0.1mol of 4,4'-diaminodiphenyl ether powder and add it to 250ml of cyclohexanone, after dissolving, add 0.1mol of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride powder, under stirring condition Gradually heat, polycondensate at 80°C for 1 hour, and the powder gradually dissolves in cyclohexanone. When the temperature rises to about 142°C, the generated water and cyclohexanone azeotropically reflux, and continue heating to 152°C, which is the boiling point of cyclohexanone, to reflux and separate water, and the system temperature gradually rises to the boiling point of cyclohexanone. When no water drops appear in the water separator, the reaction is over, which takes about 7 hours. Filter the system after cooling down to normal temperature, dry at -0.08MPa and 280°C for 2 hours, and then pulverize to obtain light yellow poly-3,3',4,4'-diphenyl ether tetracarboxylic diphenyl ether imide Resin powder, the product yield is 95.4%.

Embodiment 2

[0036] Add 312ml of n-butyl ether to the three-necked flask, add 0.1mol of all-meta-triphenylenediamine diamine, add 0.1mol of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride after dissolving, and stir well Polycondensate at 110°C for 3 hours, gradually raise the temperature to 142°C, which is the boiling point of n-butyl ether, and reflux to separate water. The reaction was stopped when water was no longer present in the trap, which took about 7 hours. After the system was cooled to room temperature, it was filtered. The filter cake was gradually heated to 250° C. and vacuum-dried at -0.09 MPa for 3 hours. After pulverization and sieving, light yellow poly-3,3',4,4'-diphenyl ether tetraformyl all-m-triphenylene imide resin powder was obtained. The product yield is 95.1%.

[0037] Using m-cresol as a solvent, the intrinsic viscosity test is carried out with a solution with a concentration of 0.5g of pure resin / 100ml: after dissolving the resin in m-cresol, a clear solu...

Embodiment 3

[0039] Add 500ml of cyclohexanone to the three-necked flask, add accurately weighed 0.1mol of all-m-triphenylether diamine, dissolve it and add 0.1mol of 2,3',3,4'-diphenyl ether dianhydride, at 105°C After polycondensation for 7 hours, the temperature was gradually raised to reflux to 152°C, which is the boiling point of cyclohexanone. The reaction was stopped when water was no longer present in the trap, which took about 7 hours. After cooling down to normal temperature, semi-imidized polyimide semi-finished products are formed.

[0040] The solution was coated on a glass plate, and the cyclohexanone was dried at 120°C for 2 hours under the protection of nitrogen, and then heated to 250°C for 4 hours, and then the glass plate was taken out after cooling down. Immerse the glass plate in water, peel off the polyimide film, and dry it under normal pressure at 100°C for 2 hours to obtain golden yellow poly-2,3',3,4'-diphenyl ether tetracarboxylic triphenyl ether Imine transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com