Coupled photon-plasmon micro cavity with focused energy, preparation method and applications thereof

A technology of plasmons and surface plasmons, applied in optical components, optical, electrical components, etc., can solve the problems of large absorption loss of metal structures, focusing coupling, and low utilization rate of incident light sources, etc., to improve the magnetic field strength , the effect of improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

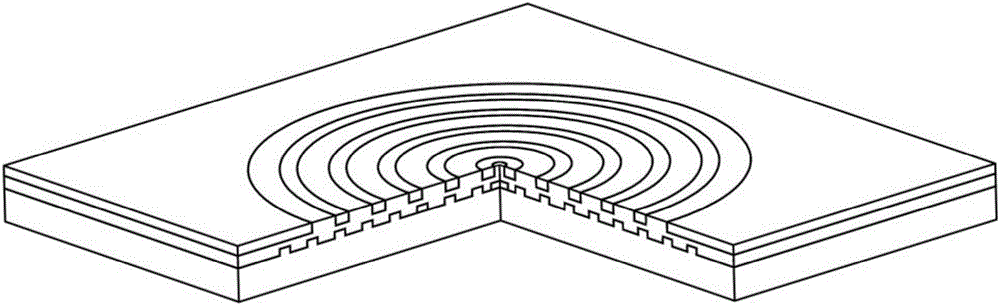

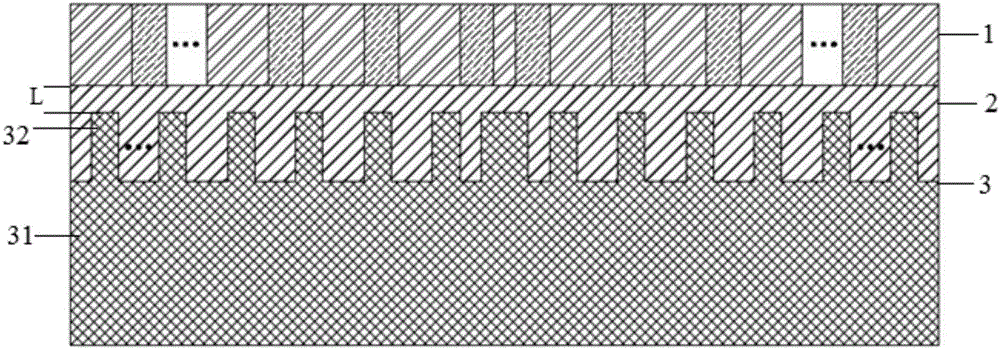

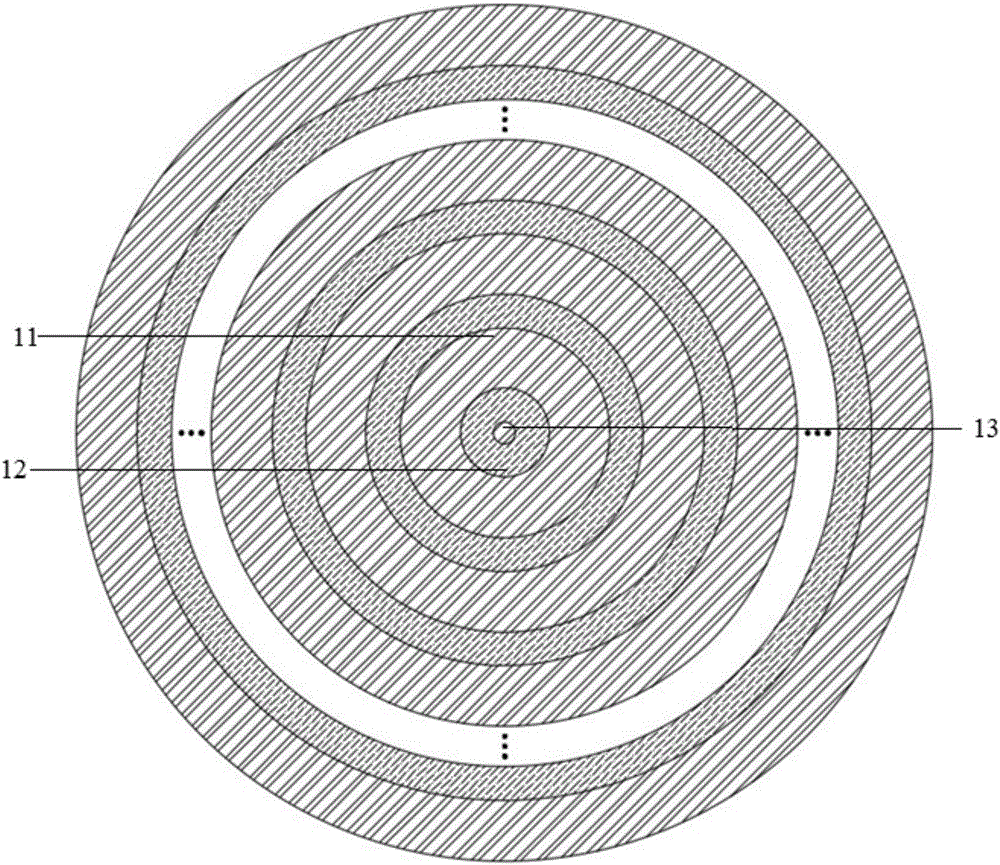

[0028] In this embodiment, the wavelength of incident light is 850 nm. As shown in Figure 1, the coupled photon-plasmon microcavity of this embodiment includes: Bragg nanometer microcavity 1, coupling layer 2 and metal surface plasmon lens 3; wherein, the central dielectric cylinder and the periphery are two different Dielectric concentric rings with alternating refractive indices constitute the Bragg nano-cavity 1, and the refractive index and ring width of the two dielectric rings meet the Bragg reflection conditions; the metal surface plasmon lens 3 includes a substrate and a substrate on the substrate. The central metal cylinder and the concentric metal rings arranged periodically on the periphery; the Bragg nano-cavity and the metal surface plasmon lens are connected by a coupling layer, and the coupling layer 2 fills the gap between the concentric metal rings, and the upper surface is high The distance from the upper surface of the concentric metal ring is L.

[0029] S...

Embodiment 2

[0036] In this embodiment, the wavelength of incident light is 1620 nm. The period of the two concentric dielectric rings with different refractive indices that the Bragg nano-microcavity includes is 1400nm; the diameter of the dielectric cylinder 13 of the first dielectric in the center of the Bragg nano-micro-cavity is 400nm; the first concentric dielectric ring 11 The width is 900 nm; the width of the second concentric dielectric ring 12 is 500 nm. The distance L between the upper surface of the coupling layer 2 and the surface of the concentric metal ring is 250 nm. The period of the metal ring 32 of the metal surface plasmon lens 3 is 1000nm, the width is 400nm, and the diameter of the innermost metal cylinder is 700nm; the distance between the innermost central cylinder and the innermost metal ring is 300nm. Others are the same as Example 1.

[0037] The size parameters of the bowtie nanoantenna placed on the energy-focused coupled photon-plasmon microcavity of this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com