Device and method for preparing composite material used for field pipeline enhancement

A technology for composite materials and preparation devices, which is applied in applications, pipe components, mechanical equipment, etc., can solve the problems of affecting the repair effect, damage of the repair effect, and non-impregnation of fiber cloth, so as to improve the infiltration effect, improve construction efficiency, and improve The effect of infiltration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

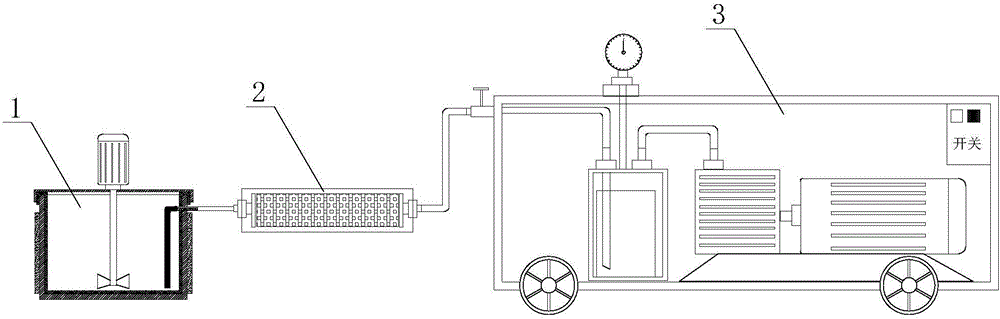

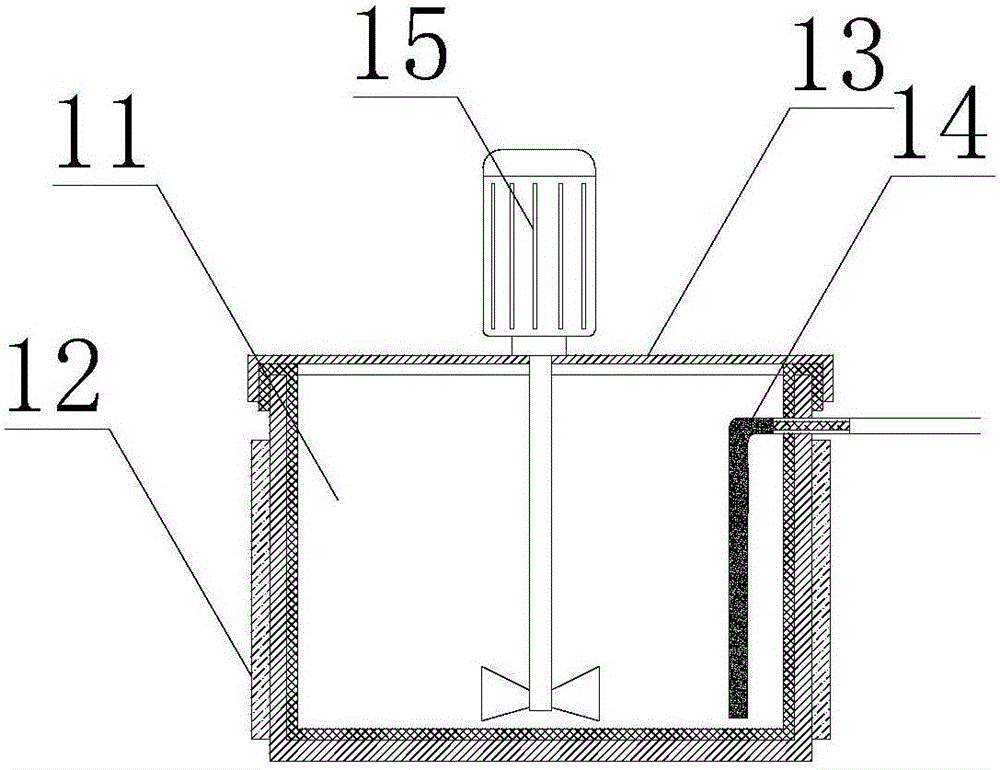

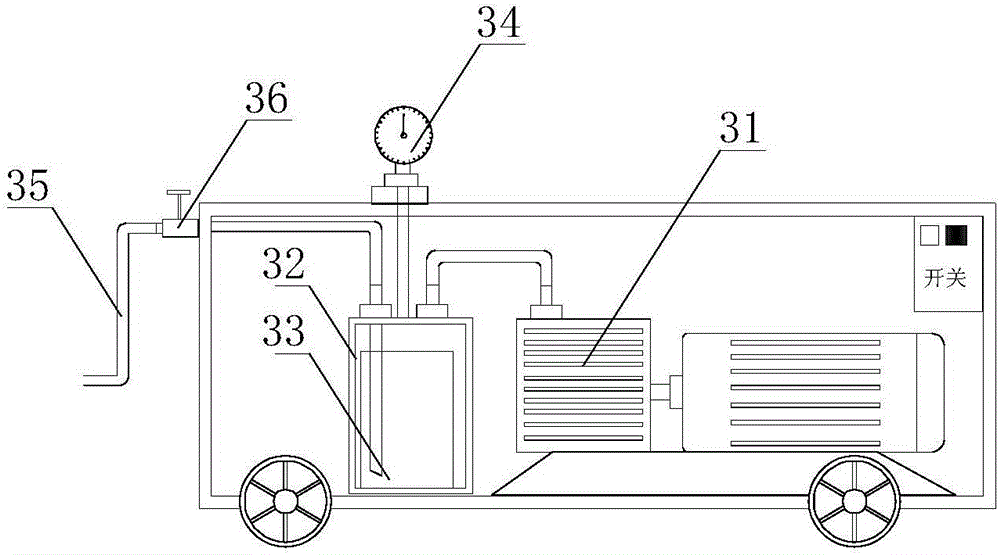

[0040] Example 1: see Figure 1 to Figure 6 , a composite material preparation device for on-site pipeline reinforcement, comprising a temperature-controlled stirring device 1, a reinforced fiber cloth soaking device 2, and a vacuum device 3, the temperature-controlled stirring device 1, a reinforced fiber cloth soaking device 2, and a vacuum device 3 connected sequentially, the reinforced fiber cloth soaking device 2 is composed of a reel 21, a vacuum bag film 28, a reinforced fiber cloth 22 and a flow guide net 23, and the reinforced fiber cloth 22 and the flow guide net 23 are distributed in layers at intervals, And stacked on the reel 21, the vacuum bag film 28 is sleeved outside the reel 21, the reinforced fiber cloth 22 and the flow guide net 23, and the reel 21 is covered with two baffles 27 that play a position-limiting role. The reinforced fiber cloth 22 and the guide net 23 are located between the two baffles 27, the inside of the baffle 27 is concave to form a rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com