Urban rail vehicle wheel composite damping vibration attenuation noise reduction device

A technology for vibration reduction and noise reduction, urban rail vehicle, applied in the field of rail vehicle vibration reduction, can solve the problems of damping wheel vibration energy, not achieving rigid collision friction, unfavorable for energy saving and environmental protection vehicle operation safety and installation, etc. Vibration peak, the effect of reducing wheel vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

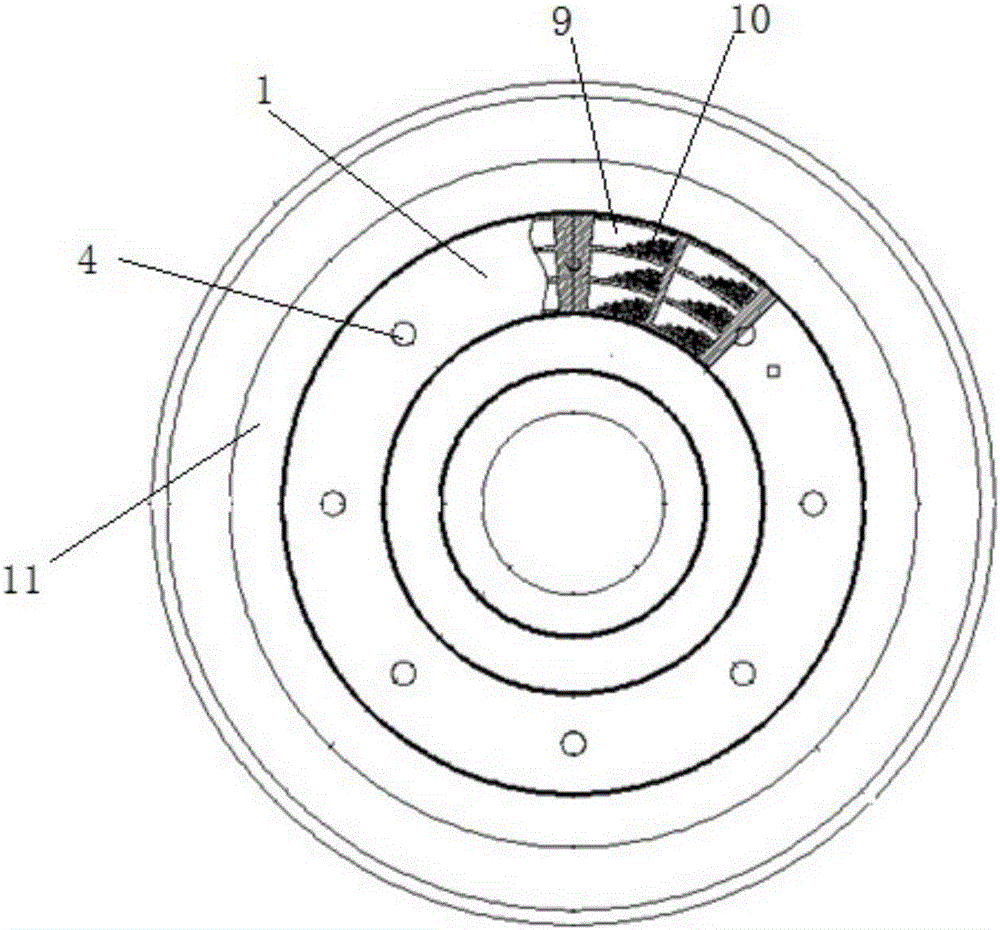

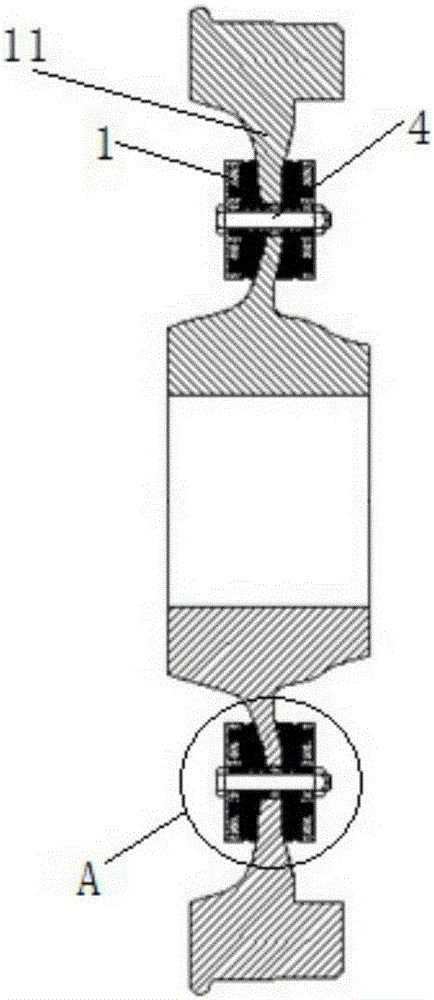

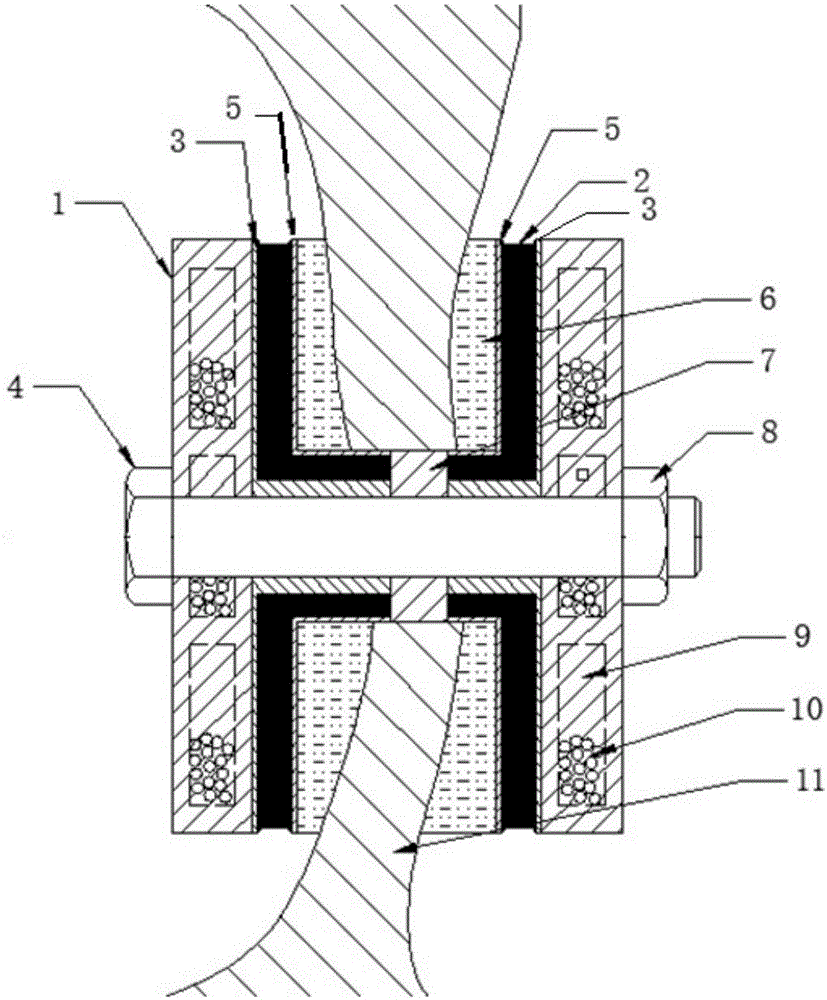

[0034] Such as Figure 1~2 As shown, the present invention is a compound type damping, vibration reduction and noise reduction device for urban rail vehicle wheels. The device includes two noise reduction assemblies, which are all concentric with the wheel web 11. On both sides of the wheel web 11 , each noise reduction assembly includes a concentric ring-shaped particle damping mechanism, a filling medium layer 6 and an elastic damping layer 2 between them.

[0035] The filling medium layer 6 is in the shape of a ring as a whole, and is made of wood material. The contact surface with the wheel web 11 is cut according to the shape of the wheel web 11 , and is closely attached to the wheel web 11 .

[0036] The particle damping mechanism is composed of an annular particle damping container 1 and a particle damping material 10 located in the particle damping container 1. The particle damping container 1 is provided with three radially distributed and annular chamber units, each ...

Embodiment 2

[0041] This embodiment is basically the same as Embodiment 1, except that the elastic damping layer 2 in this embodiment is rubber in a compressed state, and the compression of the rubber is realized by a rubber compression component, and the compression amount of the rubber is 20%. The composite damping vibration reduction and noise reduction device has a wide range of applications, small changes to the original structure of the wheel, small additional mass, wide operating frequency range, obvious vibration reduction effect, and both tuning mass damping and particle damping characteristics, especially for high-frequency vibration The noise suppression effect is good.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, except that the elastic damping layer 2 in this embodiment is rubber in a compressed state, and the compression of the rubber is realized by a rubber compression component, and the compression amount of the rubber is 25%. The composite damping vibration reduction and noise reduction device has a wide range of applications, small changes to the original structure of the wheel, small additional mass, wide operating frequency range, obvious vibration reduction effect, and both tuning mass damping and particle damping characteristics, especially for high-frequency vibration The noise suppression effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com