A method for producing carbon microspheres and the device used therein

A production method and carbon microsphere technology, which are applied in the field of carbon microsphere production, can solve the problems of reducing the safety factor of the workplace, being unfavorable to environmental protection, and unfavorable to equipment, etc., and achieving low production cost, high production efficiency, and high product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

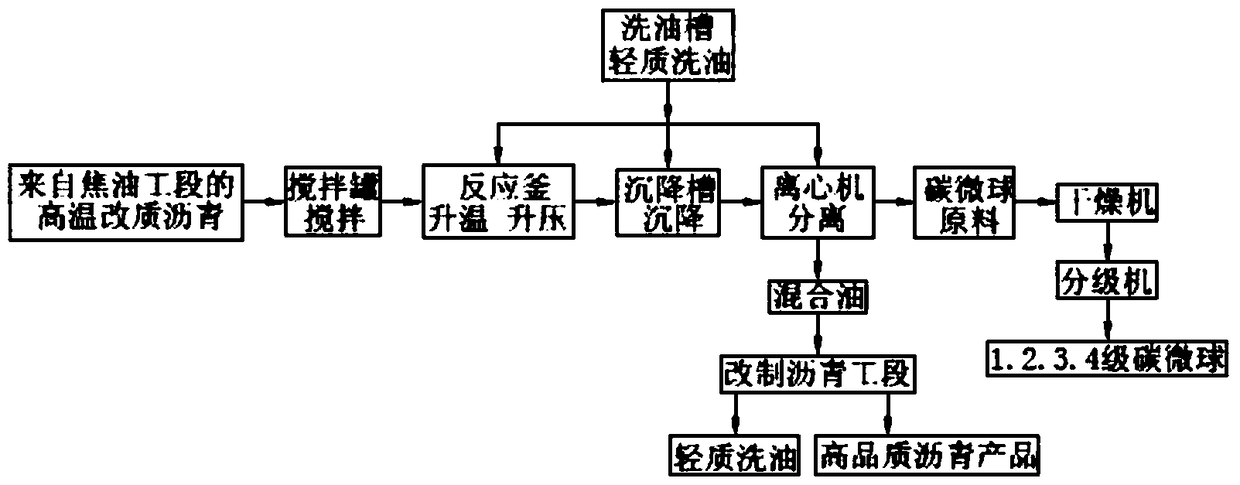

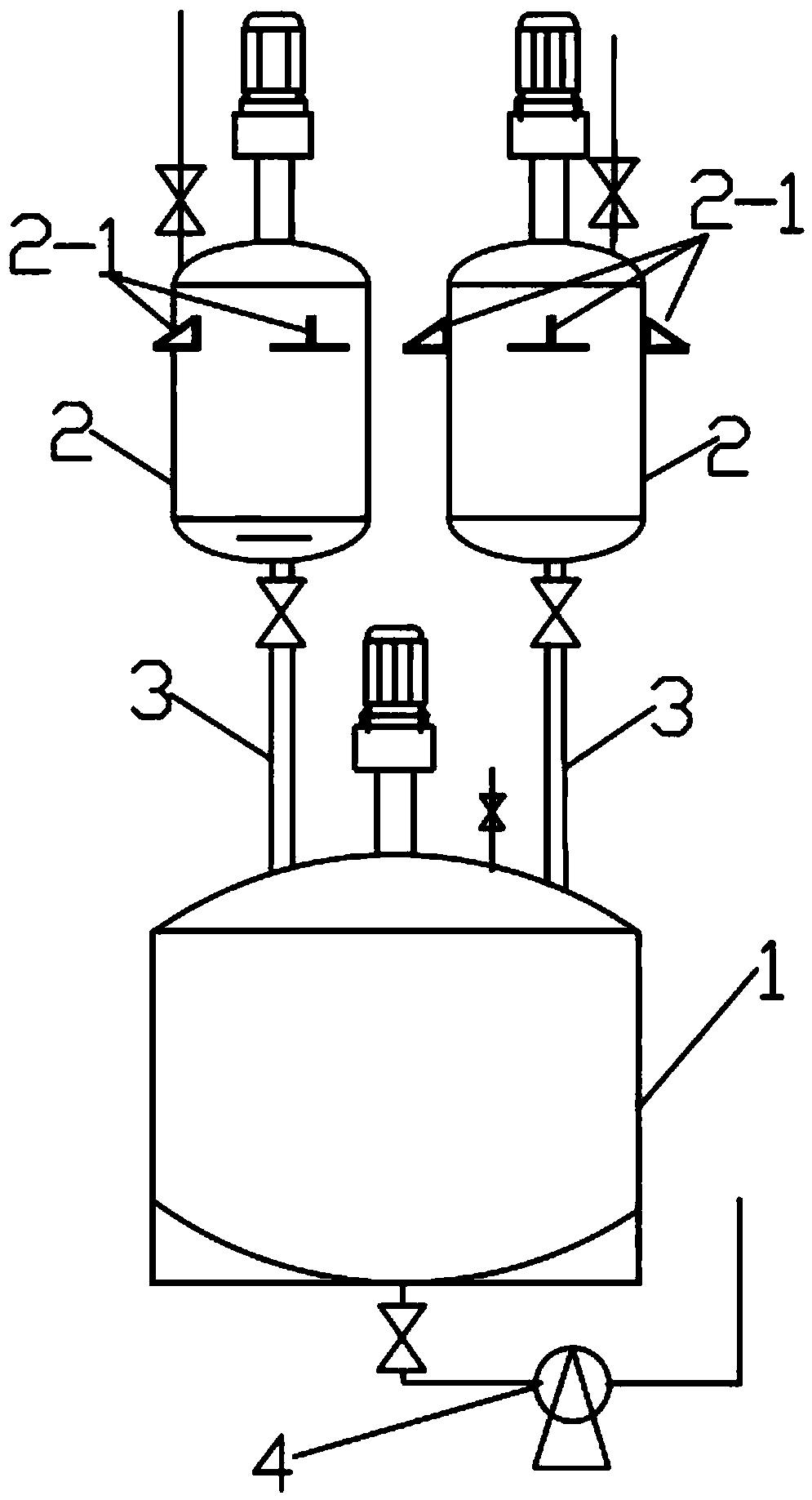

[0021] see figure 1 In an embodiment, the high-temperature liquid modified asphalt raw material from the tar plant section is transported to a mixing tank for stirring, and after being evenly stirred, it is transported to the reactor through a pipeline. The reactor is pre-heated to about 220° before the raw material liquid is transported. When it reaches about 78% of the reactor, stop feeding to meet the requirements of synchronous boosting of raw materials in the process of heating up in the closed reactor, and at the same time open the stirrer in the reactor to stir the raw materials. h Raise the temperature of the raw material at a uniform speed. When the temperature of the modified asphalt raw material liquid in the reactor is raised to 438°-440°, the pressure is basically maintained between 780kP-800kP; After the constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com