Pretreatment method for chemical industry wastewater

A chemical wastewater pretreatment technology, applied in high salt, high ammonia nitrogen, highly toxic chemical wastewater pretreatment, high organic solvent field, can solve the complex composition of chemical wastewater, biochemical treatment inhibition, increase the load of biochemical system and other problems, to reduce Fine suspended matter, reduce ammonia nitrogen load, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

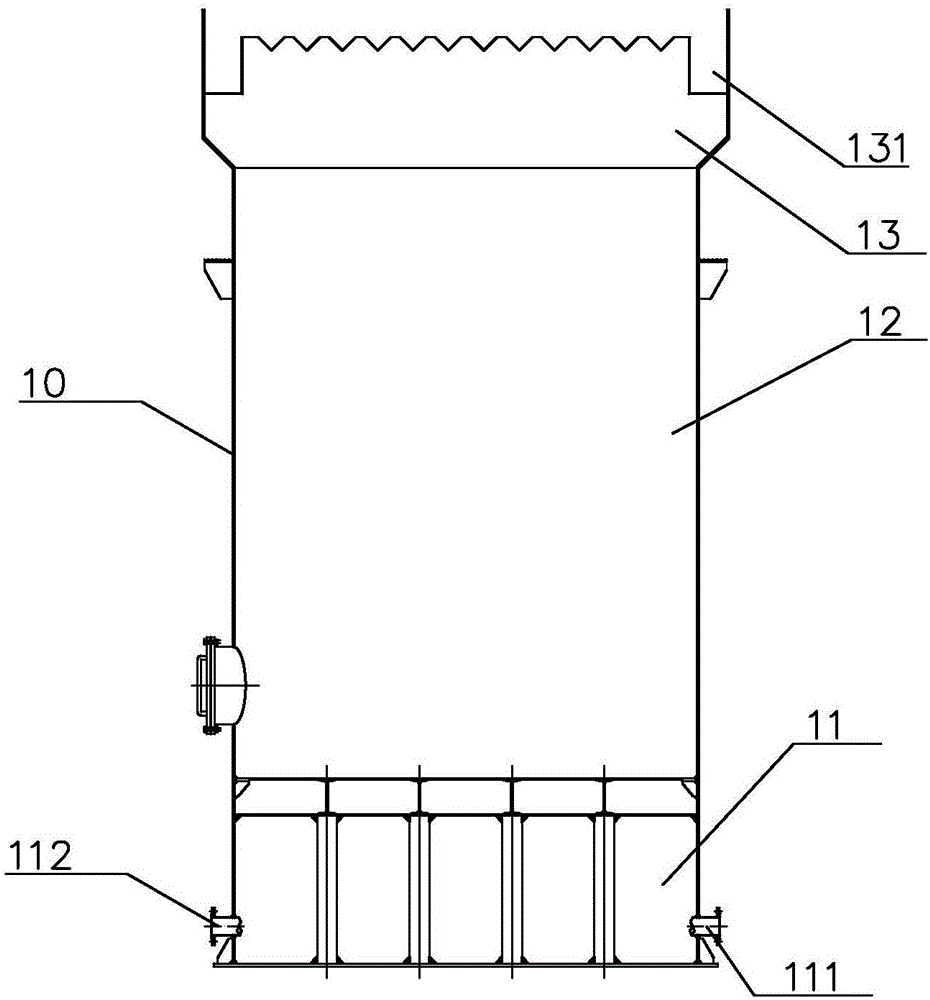

Image

Examples

Embodiment 1

[0030] Select high-salt, high-ammonia-nitrogen, high-organic-solvent, and highly-toxic chemical wastewater to undergo coagulation reaction precipitation treatment, micro-electrolysis reaction treatment, Fenton reaction treatment, MVR evaporation treatment, and condensate biochemical treatment in sequence;

[0031] Wherein said coagulation reaction precipitation process adopts PAC as coagulant, and PAM is as coagulant aid, and described PAC dosage is 98mg / L, and described PAM dosage is 11mg / L, and the described coagulation reaction precipitation The pH value is controlled at 6 by sulfuric acid adjustment;

[0032] Control the pH value at 2.8 during the micro-electrolysis reaction process;

[0033] H during the Fenton reaction process2 o 2 Dosage 9g / L, FeSO 4 The dosage is 180g / L, the dosage of PAM is 4mg / L, and the pH value is adjusted and controlled at 2.8 by sulfuric acid;

[0034] The pH value is controlled at 5 during the MVR evaporation process.

Embodiment 2

[0036] This embodiment is the same as the pretreatment method of embodiment 1, but the corresponding process parameters have been adjusted, specifically:

[0037] Wherein the dosage of PAC in the coagulation reaction precipitation treatment is 102mg / L, the dosage of PAM is 9mg / L, and the pH value of the coagulation reaction precipitation is controlled at 9 by sulfuric acid adjustment;

[0038] Control the pH value at 3.2 during the micro-electrolysis reaction process;

[0039] H during the Fenton reaction process 2 o 2 Dosage 10g / L, FeSO 4 The dosage is 220g / L, the dosage of PAM is 6mg / L, and the pH value is adjusted and controlled at 3.2 by sulfuric acid;

[0040] The pH value is controlled at 6 during the MVR evaporation process.

Embodiment 3

[0042] This embodiment is the same as the pretreatment method of embodiment 1, but the corresponding process parameters have been adjusted, specifically:

[0043] Wherein the dosage of PAC in the coagulation reaction precipitation treatment is 100mg / L, the dosage of PAM is 10mg / L, and the pH value of the coagulation reaction precipitation is controlled at 7 by sulfuric acid adjustment;

[0044] Control the pH value at 3 during the micro-electrolysis reaction process;

[0045] H during the Fenton reaction process 2 o 2 Dosage 9.6g / L, FeSO 4 The dosage is 200g / L, the dosage of PAM is 5mg / L, and the pH value is adjusted and controlled at 3 by sulfuric acid;

[0046] The pH value is controlled at 5.5 during the MVR evaporation process.

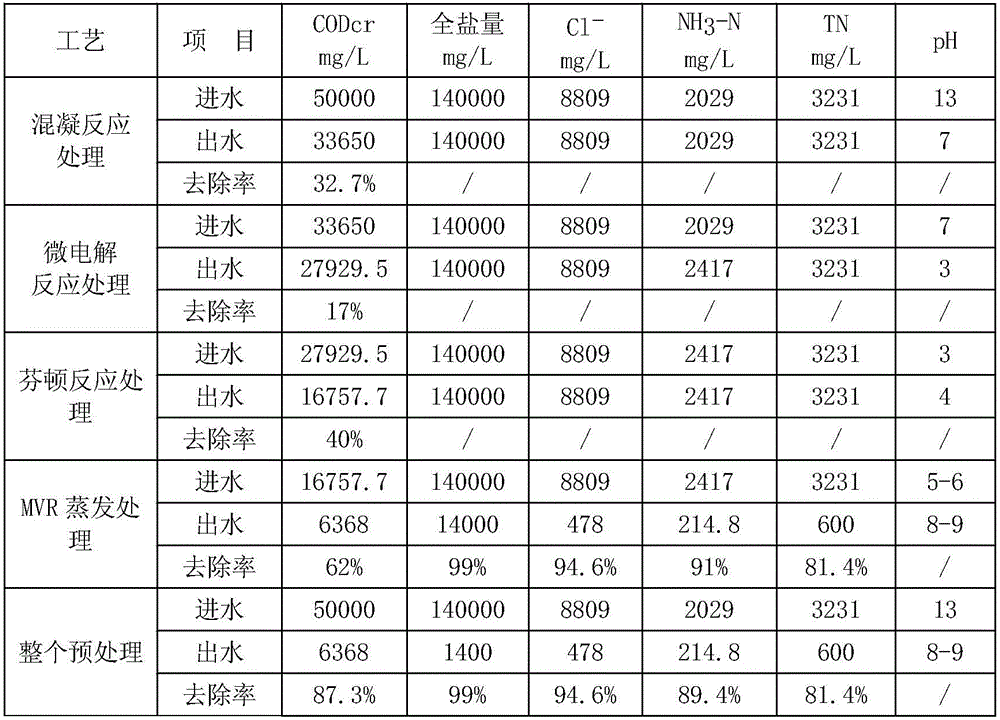

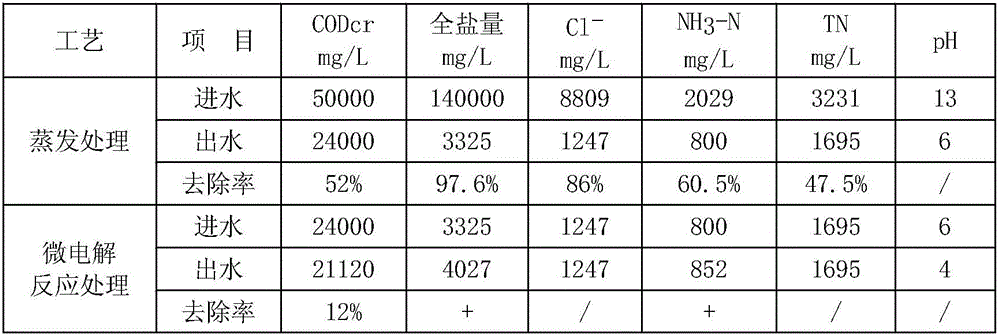

[0047] The pretreatment method of the present invention was used for the first time in a chemical wastewater treatment project of a listed company in Lai'an County. Before the application of the pretreatment method in production, it was succes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com