Method for preparing composite polytetrafluoroethene conductive material

A technology of polytetrafluoroethylene and conductive materials, which is applied in the production field of composite polytetrafluoroethylene conductive materials to achieve excellent conductivity, promote uniform dispersion, and avoid aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

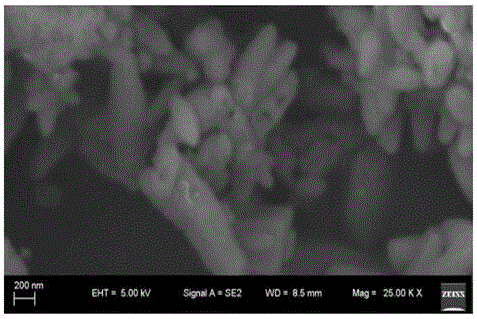

[0023] Mix polytetrafluoroethylene with a particle size of 25 μm and modified graphene microflakes with a thickness of 15 to 20 nm in a mass ratio of 90:10, and prepare a uniform mixture of graphene microflakes and polytetrafluoroethylene by mechanical blending material.

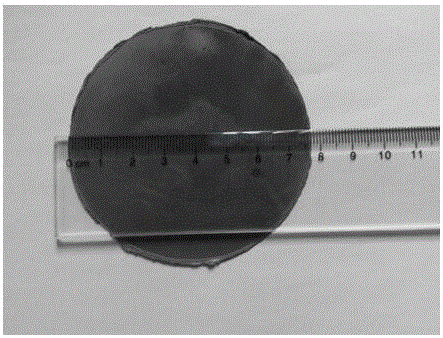

[0024] The prepared powder was cold-pressed under a pressure of 35MPa and kept under pressure for 2 minutes. The obtained flake sample was removed from the mold, placed in a muffle furnace, raised to 370-380°C at a heating rate of 200°C / hour, kept for 2 hours, and then the sintered product was cooled to room temperature with the furnace to obtain a composite polyquaternary Vinyl fluoride conductive material.

[0025] The composite polytetrafluoroethylene conductive material is tested according to GB / T 1040-92, its elongation at break: 233.02%, tensile strength: 16.02MPa. GB / T 3960-1983 detection, its wear amount: 18mg, friction coefficient: 0.29. At room temperature, bulk conductivity: 0.1 S / cm.

Embodiment 2

[0027] Mix polytetrafluoroethylene with a particle size of 25 μm and modified graphene microflakes with a thickness of 15 to 20 nm at a mass ratio of 87:13, and prepare a uniform mixture of graphene microflakes and polytetrafluoroethylene by mechanical blending.

[0028] The prepared powder was cold-pressed under a pressure of 35MPa and kept under pressure for 2 minutes. The obtained flake sample was removed from the mold, placed in a muffle furnace, raised to 370-380°C at a heating rate of 200°C / hour, kept for 2 hours, and then the sintered product was cooled to room temperature with the furnace to obtain a composite polyquaternary Vinyl fluoride conductive material.

[0029] The composite polytetrafluoroethylene conductive material is tested according to GB / T 1040-92, its elongation at break: 119.41%, tensile strength: 15.74MPa. GB / T 3960-1983 detection, its wear amount: 9.8mg, friction coefficient: 0.20. At room temperature, volume conductivity: 0.54S / cm.

Embodiment 3

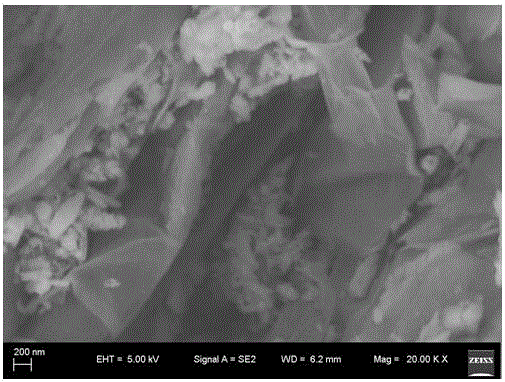

[0031] Mix polytetrafluoroethylene with a particle size of 25 μm and modified graphene microflakes with a thickness of 15-20 nm at a mass ratio of 85:15, and prepare a homogeneous mixture of polytetrafluoroethylene composite materials by mechanical blending.

[0032] The prepared powder was cold-pressed under a pressure of 40 MPa, and kept under pressure for 2 minutes. The obtained flake sample was removed from the mold, placed in a muffle furnace, raised to 370-380°C at a heating rate of 200°C / hour, kept for 2 hours, and then the sintered product was cooled to room temperature with the furnace to obtain a composite polyquaternary Vinyl fluoride conductive material.

[0033] The composite polytetrafluoroethylene conductive material is tested according to GB / T 1040-92, its elongation at break: 7.40%, tensile strength: 15.21MPa. GB / T 3960-1983 detection, its wear amount: 18.6mg, friction coefficient: 0.23. At room temperature, bulk conductivity: 0.57 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com