High-weather-resistant TPU film and preparation method thereof

A technology of high weather resistance and thin film, which is applied in the field of TPU film and its preparation, can solve the problems of TPU film toughness increase, etc., and achieve the effects of improving light resistance stability, increasing heat resistance stability, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

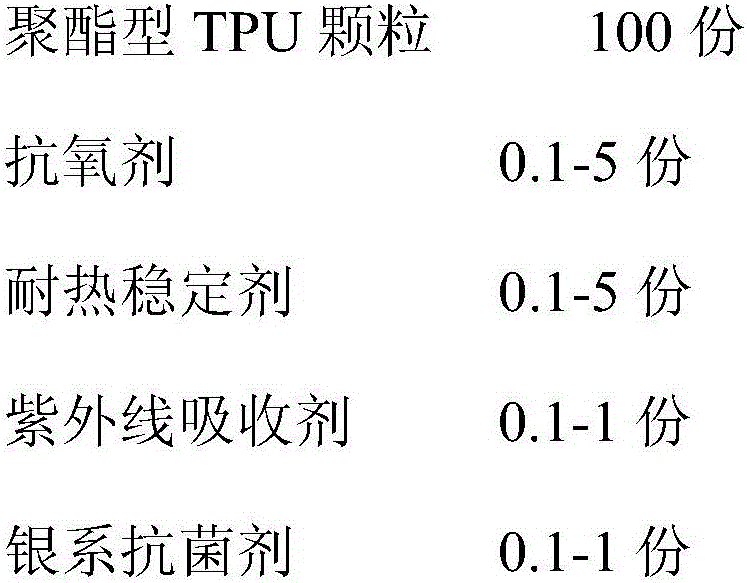

[0041] A kind of high weather resistance TPU film, comprises following composition by weight part:

[0042]

[0043] Wherein, the heat-resistant stabilizer is a combination of tin stabilizer and zinc stearate;

[0044] Described antioxidant is that the combination of antioxidant 1010 and phosphite antioxidant 618 molar ratio is 1:5;

[0045] Described heat-resistant stabilizer is the combination that methyl ester group tin mercaptide stabilizer and zinc stearate mol ratio are 1:2;

[0046] and prepared by:

[0047] (1) Dry the raw materials under vacuum at 60°C for more than 3 hours and then mix them;

[0048] (2) Melt and blend the mixed material in a high-speed mixer at 170° C. at a speed of 40,000 r / min for 3 hours to obtain a composite masterbatch;

[0049] (3) The masterbatch is processed by film blowing to obtain the TPU film.

Embodiment 2

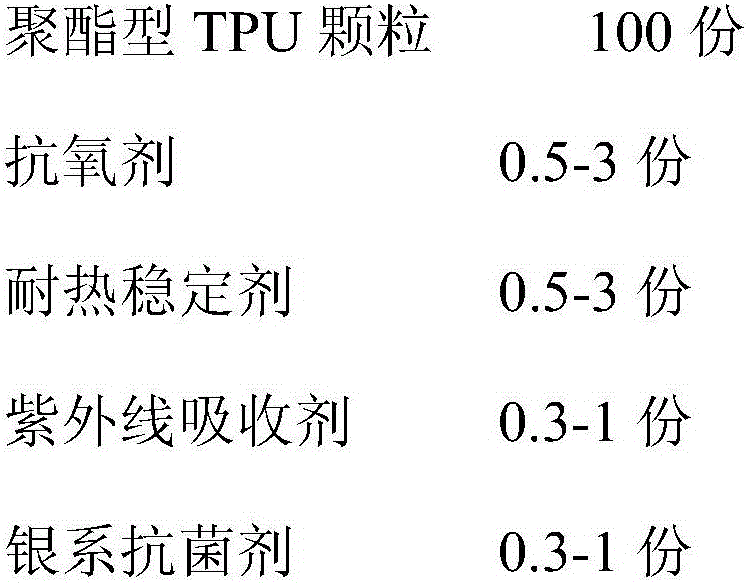

[0051] A kind of high weather resistance TPU film, comprises following composition by weight part:

[0052]

[0053] Wherein, the heat-resistant stabilizer is a combination of tin stabilizer and zinc stearate;

[0054] Described antioxidant is the combination that antioxidant 1076 and phosphite antioxidant 168 molar ratio are 1:0.2;

[0055] Described heat-resistant stabilizer is the combination that tin stabilizer and zinc stearate mol ratio are 1:0.5;

[0056] The combination of the ultraviolet absorber phenyl salicylate and 2,4-dihydroxybenzophenone molar ratio 1:3;

[0057] The silver-based antibacterial agent is silver-loaded zirconium phosphate;

[0058] and prepared by:

[0059] (1) Dry the raw materials under vacuum at 70°C for more than 5 hours and then mix them;

[0060] (2) Melt and blend the mixed material in a high-speed mixer at 150°C with a rotation speed of 50,000r / min for 0.5h to obtain a composite masterbatch;

[0061] (3) Carrying out casting and film-...

Embodiment 3

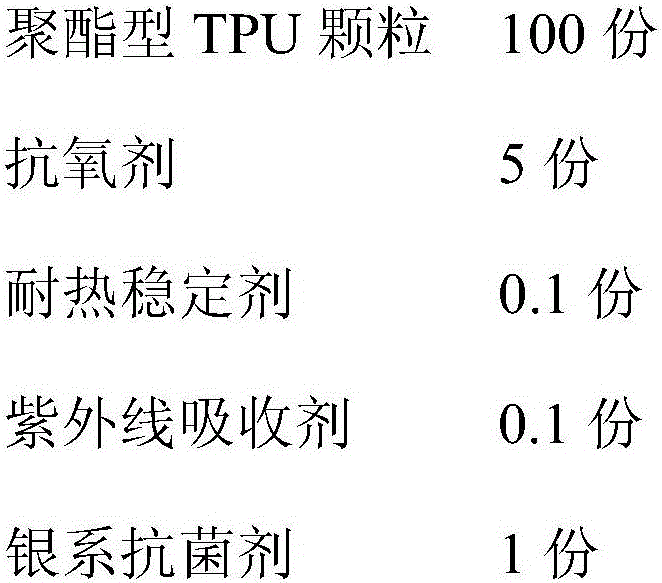

[0063] A kind of high weather resistance TPU film, comprises following composition by weight part:

[0064]

[0065] Wherein, the heat-resistant stabilizer is a combination of tin stabilizer and zinc stearate;

[0066] Described antioxidant is the combination that polyphenol antioxidant 1010 and phosphite antioxidant 168 molar ratio are 1:1;

[0067] Described heat-resistant stabilizer is the combination that methyl ester group tin mercaptide stabilizer and zinc stearate mol ratio are 1:3;

[0068] The combination of the ultraviolet absorber phenyl salicylate and 2,4-dihydroxybenzophenone molar ratio of 1:05;

[0069] The silver-based antibacterial agent is silver-loaded zirconium phosphate;

[0070] and prepared by:

[0071] (1) Mix the raw materials after drying at 50°C for 2 hours under vacuum;

[0072] (2) Melt and blend the mixed material in a high-speed mixer at 230°C with a rotation speed of 20000r / min for 2.5h to obtain a composite masterbatch;

[0073] (3) Car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com