Production method for melt direct-spinning 3D yarn

A technology of melt direct spinning and production method, which is applied in the field of textile production, and can solve the problems of weak product concavo-convexity, small application range, poor air permeability, etc., achieve excellent three-dimensional effect, increase spinning speed, and various styles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

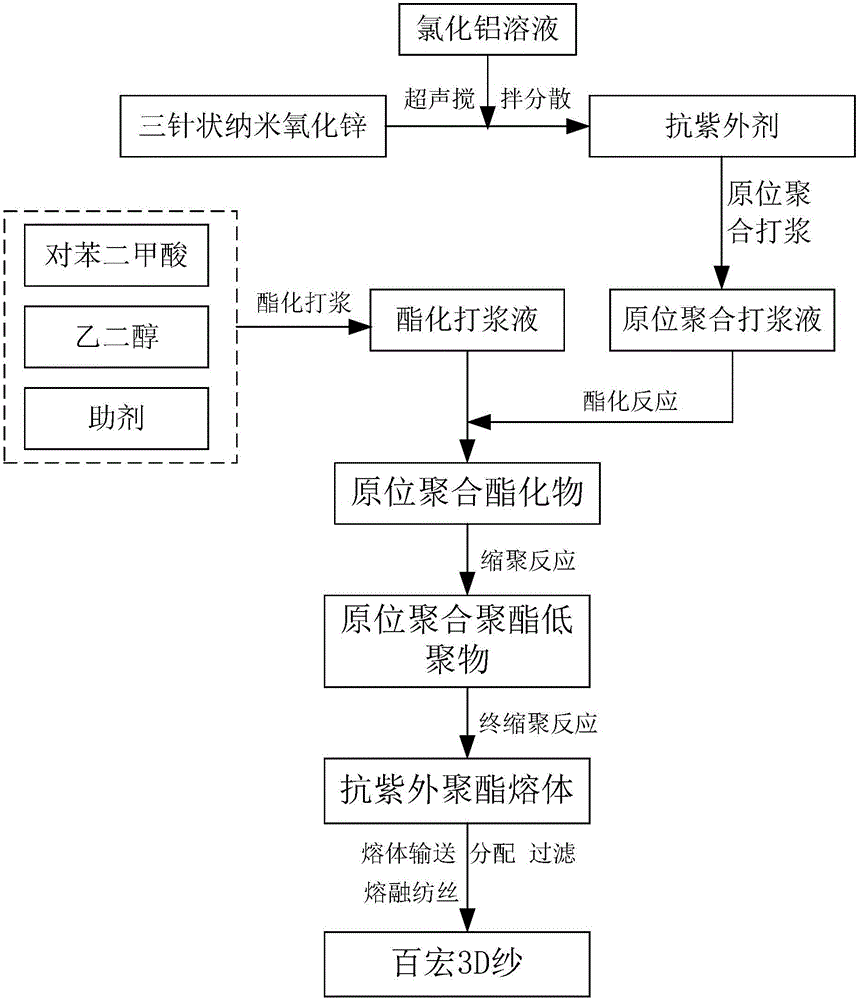

Image

Examples

Embodiment 1

[0045] A method for making Baihong 3D yarn by melt direct spinning, the specific steps are:

[0046] The preparation of the first step anti-ultraviolet agent:

[0047] Using the three-acicular nano-zinc oxide with an average particle size of 45 nanometers as the modifier, the three-acicular nano-zinc oxide is dispersed in the pH of 8-9 by the dispersion method of ultrasonic and high-speed stirring at room temperature. In the alkaline solution of ionized water, the high-speed stirring speed is 3000-4500 rpm, the dispersion time is 2-3 hours, and then the reaction temperature is 45-60 °C and the stirring speed is 1000-1500 rpm. Slowly add aluminum chloride solution to the system, control the addition of aluminum chloride solution in 45-60 minutes, then raise the reaction temperature to 80°C and continue the reaction for 30-60 minutes, so that the aluminum ions are adsorbed on the surface of the three-acicular nano-zinc oxide, and In an alkaline system, an aluminum hydroxide coa...

Embodiment 2

[0076] A method for making Baihong 3D yarn by melt direct spinning, the specific steps are:

[0077] The preparation of the first step anti-ultraviolet agent:

[0078] Using the three-acicular nano-zinc oxide with an average particle size of 50 nanometers as the modifier, the three-acicular nano-zinc oxide is dispersed in the pH of 8-9 by the dispersion method of ultrasonic and high-speed stirring at room temperature. In the alkaline solution of ionized water, the high-speed stirring speed is 3000-4500 rpm, the dispersion time is 2-3 hours, and then the reaction temperature is 45-60 °C and the stirring speed is 1000-1500 rpm. Slowly add aluminum chloride solution to the system, control the addition of aluminum chloride solution in 45-60 minutes, then raise the reaction temperature to 80°C and continue the reaction for 30-60 minutes, so that the aluminum ions are adsorbed on the surface of the three-acicular nano-zinc oxide, and In an alkaline system, an aluminum hydroxide coa...

Embodiment 3

[0106] A method for making Baihong 3D yarn by melt direct spinning, the specific steps are:

[0107] The preparation of the first step anti-ultraviolet agent:

[0108] Using the three-acicular nano-zinc oxide with an average particle size of 60 nanometers as the modifier, the three-acicular nano-zinc oxide is dispersed in the pH of 8-9 by the dispersion method of ultrasonic and high-speed stirring at room temperature. In the alkaline solution of ionized water, the high-speed stirring speed is 3000-4500 rpm, the dispersion time is 2-3 hours, and then the reaction temperature is 45-60 °C and the stirring speed is 1000-1500 rpm. Slowly add aluminum chloride solution to the system, control the addition of aluminum chloride solution in 45-60 minutes, then raise the reaction temperature to 80°C and continue the reaction for 30-60 minutes, so that the aluminum ions are adsorbed on the surface of the three-acicular nano-zinc oxide, and In an alkaline system, an aluminum hydroxide coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com