Punched and embossed non-woven fabric

A technology of non-woven fabrics and pore pressure, applied in the field of non-woven fabrics, can solve the problems of insufficient comfort and high manufacturing costs of non-woven fabrics, and achieve the effects of reducing red buttocks, easy molding rate, and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

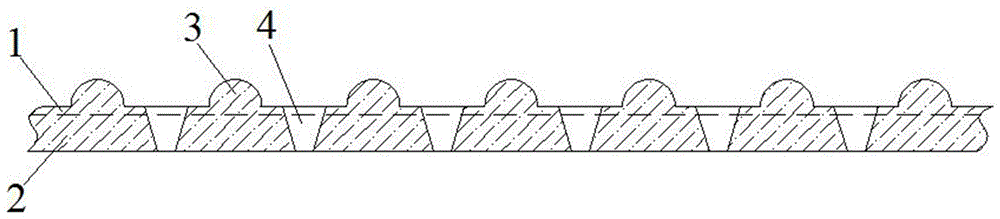

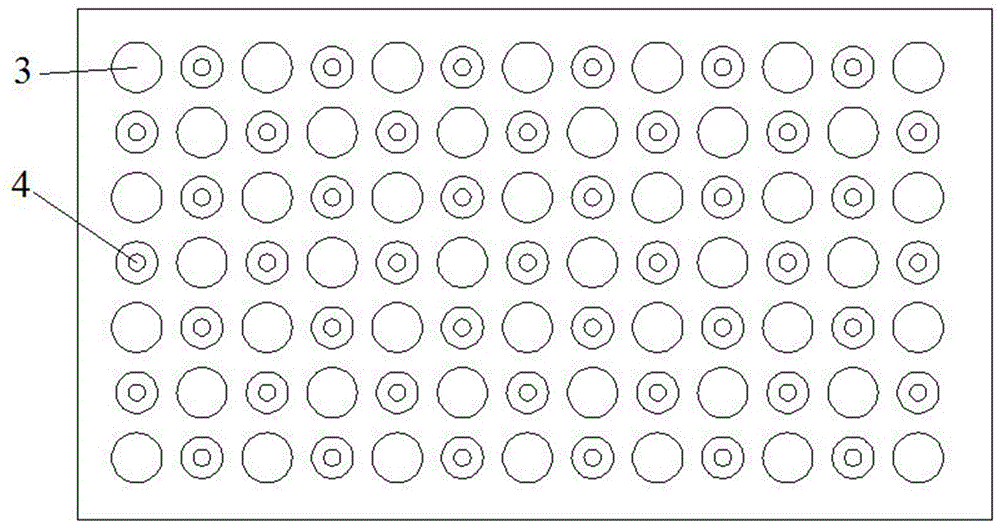

[0014] An embossed perforated non-woven fabric, which is formed by hot-rolling and bonding a surface layer 1 made of polypropylene and a bottom layer 2 made of polypropylene. The surface layer 1 is a fine-denier fiber of 1.5 denier, and the bottom layer 2 is 2.0 denier. Neil is relatively thick fiber, the upper surface of the surface layer 1 is provided with uniformly arranged semi-spherical protrusions 3, and the middle of every two adjacent protrusions 3 is provided with a conical drainage hole 4 with a large top and a small bottom, and the drainage hole 4 runs through the surface layer 1 and ground floor 2.

[0015] The surface layer 1 of thinner fibers is used as the skin-friendly layer, which is more comfortable and soft in contact with the human skin; the bottom layer 2 of thicker fibers is used as the outer layer, which has high plasticity and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com