Dragon bone waterlift type earthwork conveying system and construction method thereof

A conveying system and a waterwheel-type technology, which is applied to earth movers/shovels, construction, etc., can solve the problems of long dehydration and consolidation period of air-tight earthwork, high moisture content of conveying silt, and limited conveying distance, etc., and achieve shortening Consolidation and dehydration time, low moisture content of sludge, and the effect of increasing the conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

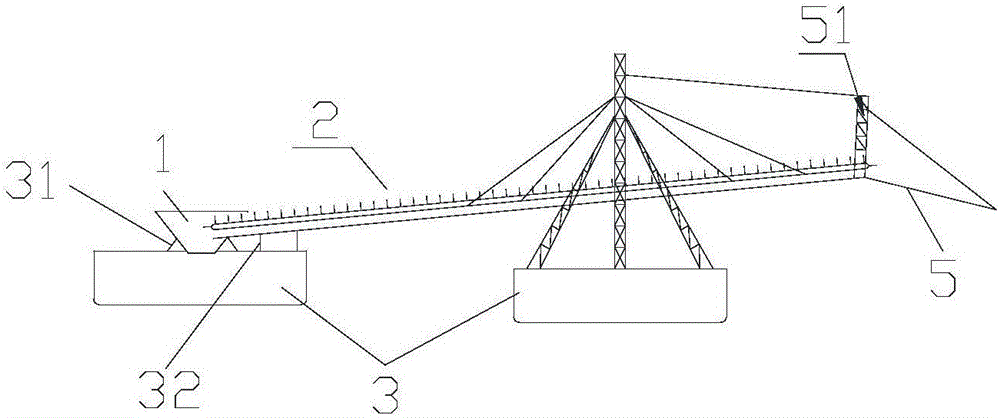

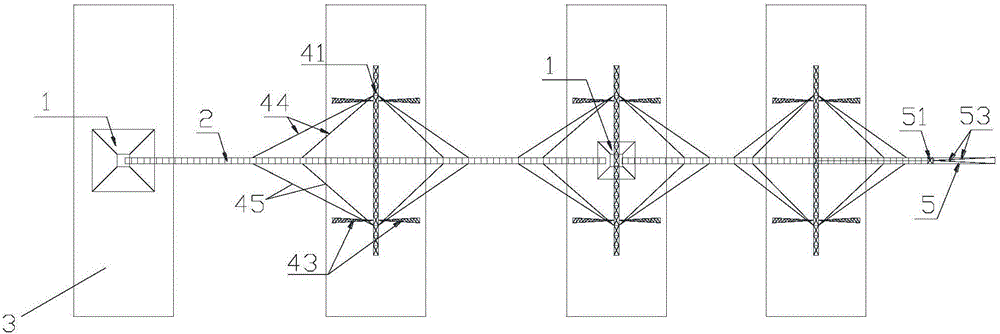

[0030] see figure 1 , Figure 4 with Figure 5 As shown, they are respectively the sectional view of the keel waterwheel type earthwork conveying system in Embodiment 1 of the present invention, the front view of the conveyor and the sectional view of the conveyor.

[0031] A keel waterwheel type earthwork conveying system includes a first-stage conveying unit, the conveying unit includes a collector 1 and a conveyor 2, and the collector 1 and the conveyor 2 both use a floating tank 3 as a fulcrum, the The end of the conveyor 2 is placed in the collector 1, the conveyor 2 includes a tank body 21 and a conveyor belt 22, the conveyor belt 22 is provided with a scraper 221, and the conveyor belt 22 is transported from above The upper conveyor belt is placed on the tank body 21 through the support shaft 23, and the lower conveyor belt is placed in the tank body 21, wherein the conveyor belt 2 is supported. The number of floating tank 3 is at least one.

[0032] In this embodim...

Embodiment 2

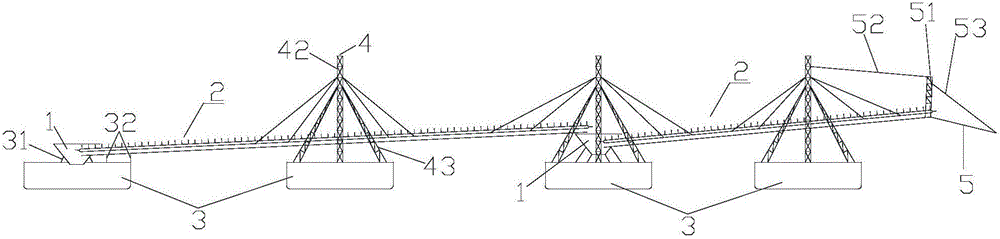

[0035] A kind of keel waterwheel type earthwork conveying system as mentioned above, the difference of this embodiment is that, as figure 2 , Figure 4 with Figure 5 As shown, they are respectively the sectional view of the keel waterwheel type earthwork conveying system in the second embodiment of the present invention and the structural schematic diagram of the conveyor.

[0036] A keel waterwheel type earthwork conveying system, comprising two-stage conveying units, respectively a first-stage conveying unit and a second-stage conveying unit, both of the first-stage conveying unit and the second-stage conveying unit include a collector 1 and conveyor 2, both of the collector 1 and the conveyor 2 use the floating tank 3 as a fulcrum, the end of the conveyor 2 is placed in the collector 1, and the conveyor 2 includes a tank 21 and a conveyor belt 22, the conveyor belt 22 is provided with a scraper 221, the conveyor belt is composed of an upper conveyor belt and a lower con...

Embodiment 3

[0039] A kind of keel waterwheel type earthwork conveying system as mentioned above, the difference of this embodiment is that, as Image 6 As shown, it is a structural schematic diagram of the skeleton of the conveyor belt of the present invention. The conveyor belt 22 is formed by connecting several skeletons 222 through fasteners 223. The scraper 221 is arranged on the skeleton 222 and the scraper The size of 221 matches the size of the tank body 21, so that when the scraper 221 scrapes the sludge in the tank body 21, the sludge scraped by the scraper 221 can be transported to the tank The end of the body 21, wherein the fastener 223 is a screw, a bolt or a pin, which is convenient for installation and disassembly. In this embodiment, the length of the transmission belt can be changed by increasing or decreasing the number of the skeletons 222 according to the actual situation.

[0040] Preferably, the scraper 221 is arranged vertically to the frame 222 and the scraper 221...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com