Three-dimensional LED epitaxial structure and preparation method thereof

An epitaxial structure, three-dimensional technology, applied in electrical components, nanotechnology, circuits, etc., can solve the problems of difficult multi-color light emission and high cost of LED epitaxial structure preparation, achieve low process cost, improve electron-hole recombination probability, ratio The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

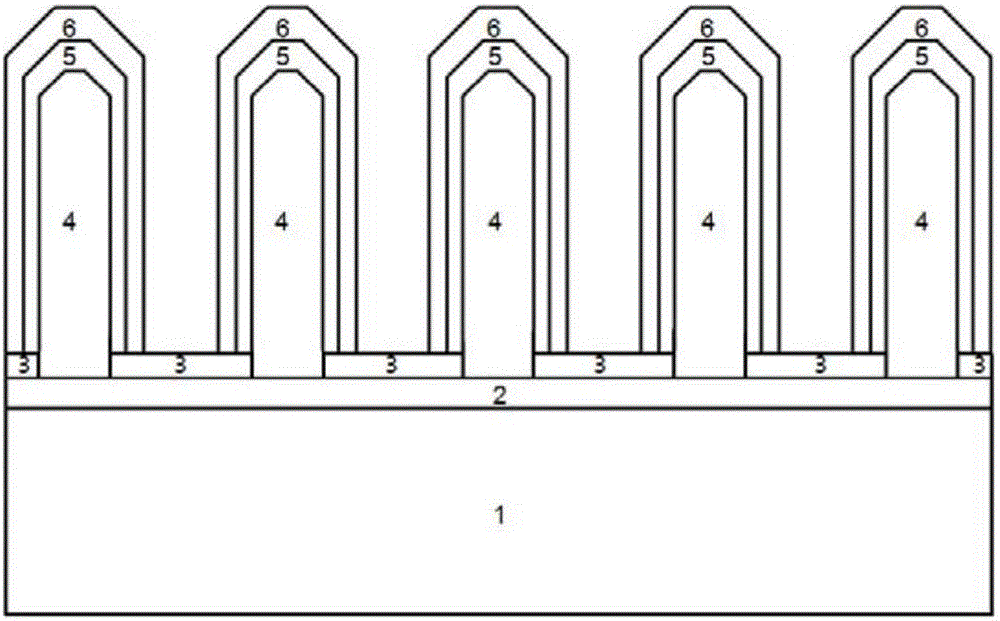

[0038] This embodiment provides a three-dimensional LED epitaxial structure, such as figure 1 As shown, it includes a substrate 1 and porous SiN stacked on the substrate 1 x layer 3; also includes the SiN x The n-type GaN nanorod array 4 in the layer pores is sequentially laminated with a multi-quantum well layer 5 and a p-type GaN layer 6 coated on each surface of the GaN nanorod array 4 .

[0039] The three-dimensional core-shell structure formed by the GaN nanorod array 4 and the multi-quantum well layer 5 and the P-type GaN layer 6 on each outer surface thereof has a large specific surface area. Compared with thin-film materials, more photons can be generated at the same current density, which improves the internal quantum efficiency of the LED epitaxial structure.

[0040] Porous SiN x Layer 3 can not only serve as a growth template for GaN nanorod array 4, but also effectively reduce the dislocation density of the structure and the continued growth of dislocations, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com