A catalyst for converting HFC-245FA into trans-1,3,3,3-tetrafluoropropene and its preparation method

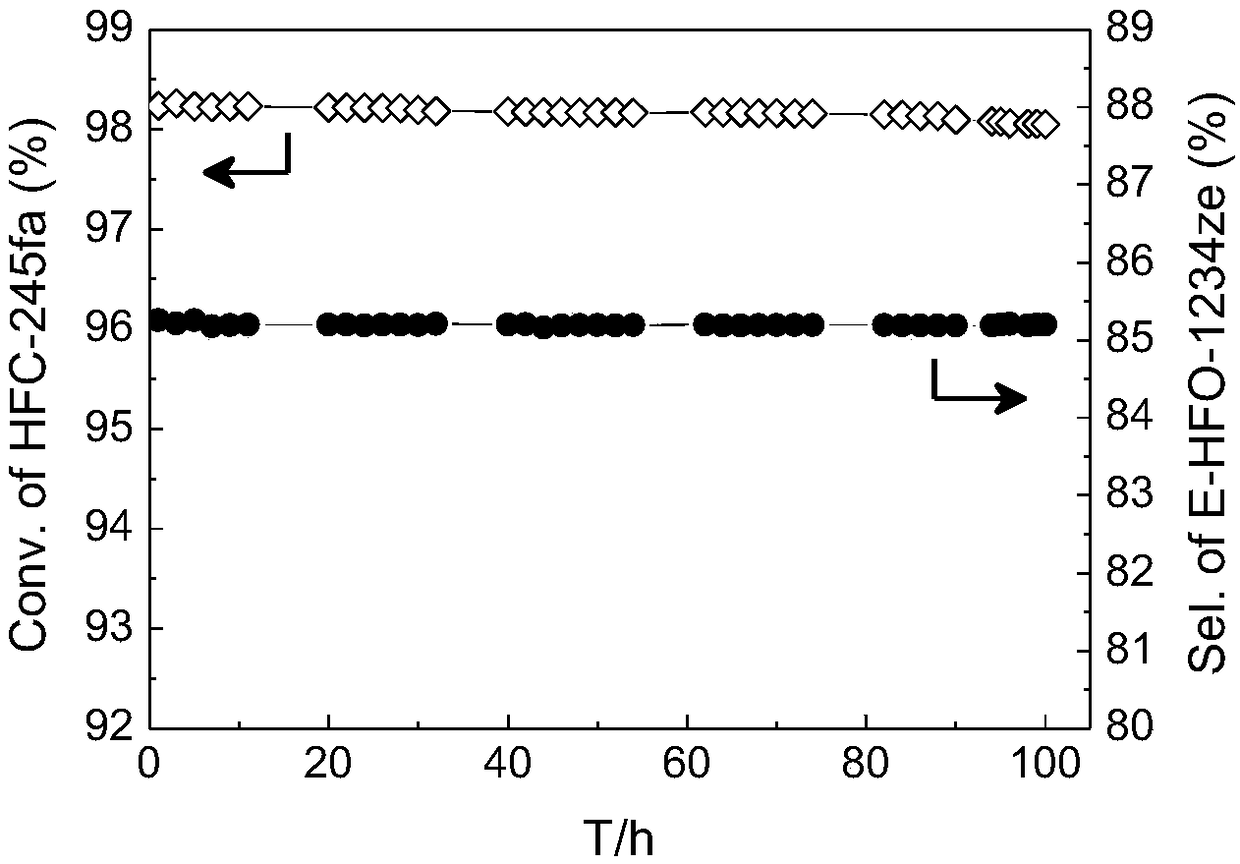

A technology of hfc-245fa and tetrafluoropropene is applied in the field of dehydrofluorination catalysts and their preparation, which can solve the problems of easy coking and deactivation of catalysts, low selectivity and low conversion rate, and achieve high conversion rate and selectivity and catalyst life. High and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1)MgCr 2 o 4 Preparation:

[0021] According to MgO and Cr 2 o 3 The molar ratio is 1:1, respectively weigh 8.0g MgO, 30.4g Cr 2 o 3 , add 40ml of water to mix, dry at 120°C, and then bake at 800°C for 4 hours to get MgCr 2 o 4 .

[0022] (2) Ag-Ni / MgCr 2 o 4 Preparation:

[0023] According to the total mass of Ag and Ni is MgCr 2 o 4 10% of the mass, where the Ag / Ni ratio (mass) is: 1:1, weigh 10g MgCr respectively 2 o 4 , 2.48gNi(NO 3 ) 2 ·6H 2 O and 0.79gAgNO 3 , then add 20ml of water to stir and impregnate, dry at 120°C, bake at 500°C for 4 hours, and then reduce in hydrogen atmosphere at 400°C for 4 hours to obtain Ag-Ni / MgCr 2 o 4 .

[0024] (3)Na 2 CO 3 / Ag-Ni / MgCr 2 o 4 Catalyst preparation method:

[0025] According to Na 2 CO 3 The load is Ag-Ni / MgCr 2 o 4 1% of mass, weigh 0.1gNa 2 CO 3 and 10gAg-Ni / MgCr 2 o 4 , and then add 20ml of water to stir and impregnate, dry, and roast at 500°C for 4 hours in a nitrogen atmosphere to ...

Embodiment 2

[0029] MgCr 2 o 4 with Ag-Ni / MgCr 2 o 4The preparation method is the same as in Example 1, except that the Ag / Ni ratio (mass) is: 1:4, Na 2 CO 3 / Ag-Ni / MgCr 2 o 4 The preparation method of catalyst is with embodiment 1, Na 2 CO 3 The load is Ag-Ni / MgCr 2 o 4 1% of mass.

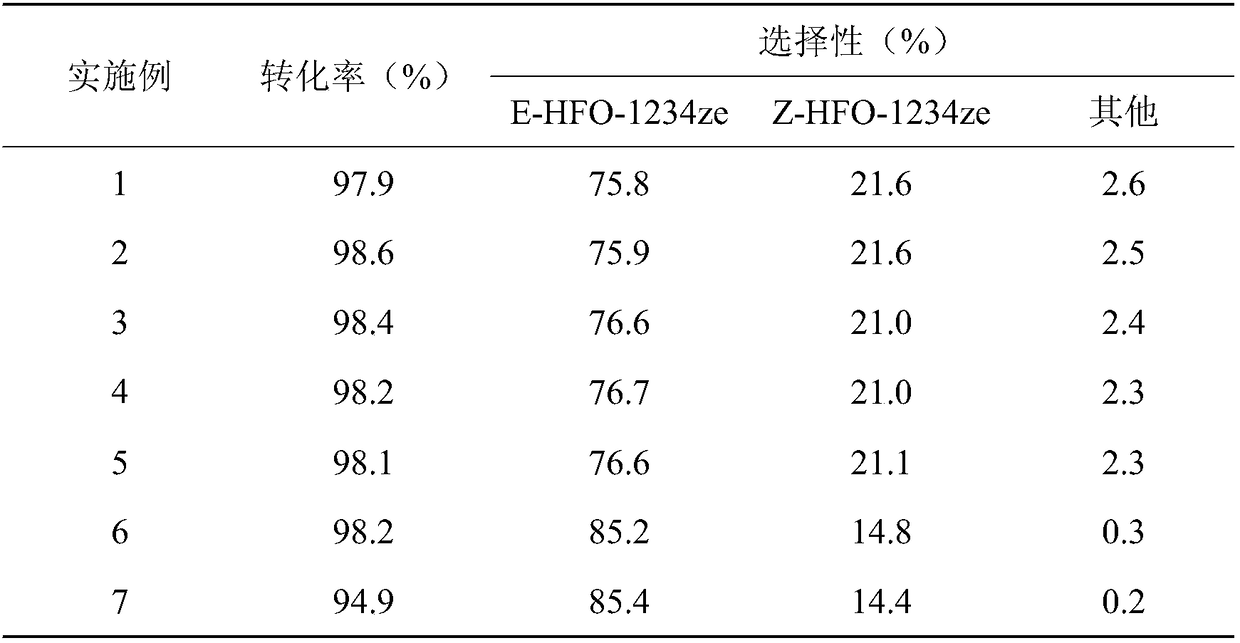

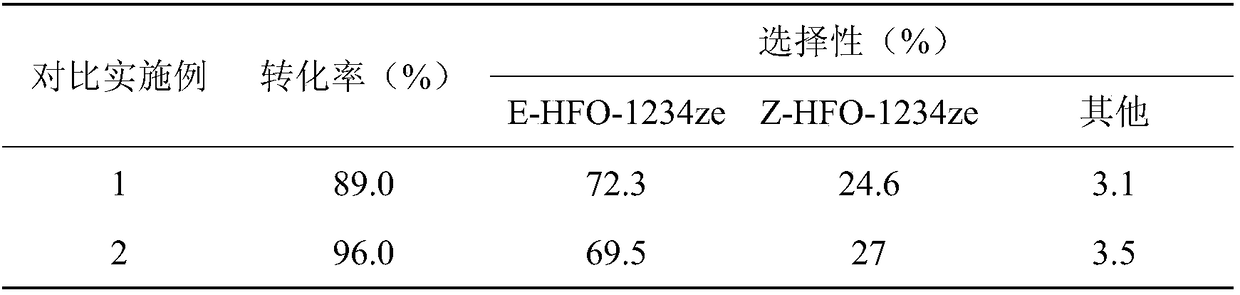

[0030] The reaction conditions and analysis and detection conditions are the same as in Example 1. The conversion rate of HFC-245fa and the selectivity of HFO-1234ze are shown in Table 1.

Embodiment 3

[0032] MgCr 2 o 4 with Ag-Ni / MgCr 2 o 4 The preparation method is the same as in Example 1, except that the Ag / Ni ratio (mass) is: 1:8, Na 2 CO 3 / Ag-Ni / MgCr 2 o 4 The preparation method of catalyst is with embodiment 1, Na 2 CO 3 The load is Ag-Ni / MgCr 2 o 4 1% of mass.

[0033] The reaction conditions and analysis and detection conditions are the same as in Example 1. The conversion rate of HFC-245fa and the selectivity of HFO-1234ze are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com