Forming method

A processing method and oil tank technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as air leakage, box tearing, and high mold consumption, so as to improve the working environment, save processing costs, and improve labor efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

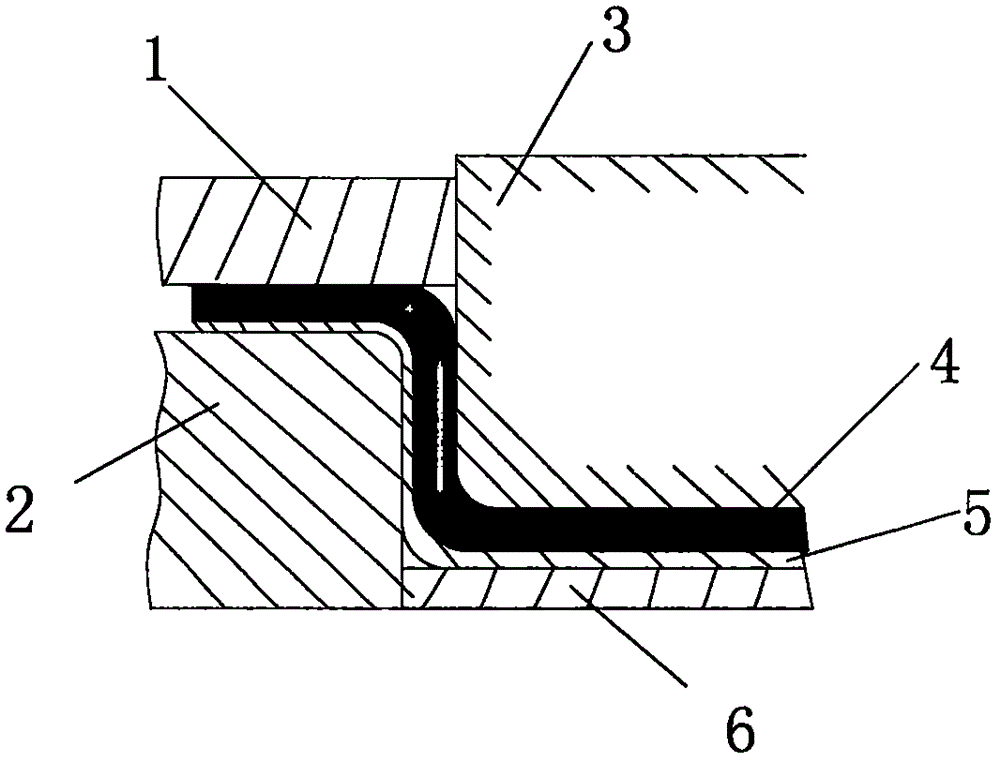

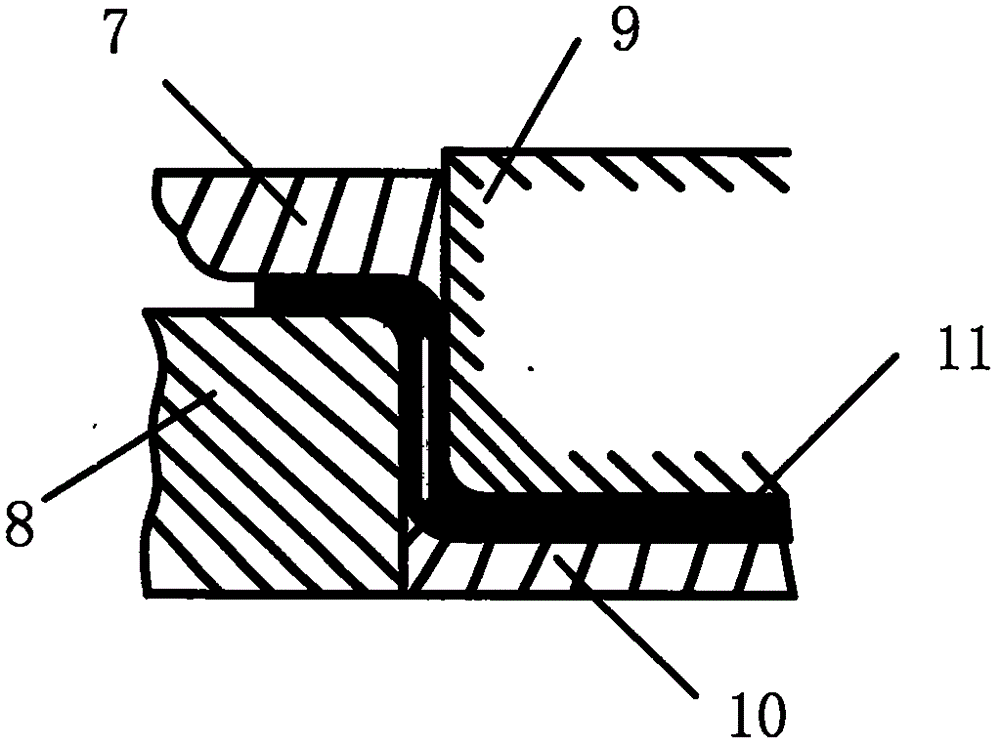

[0011] The invention changes the traditional oil tank processing method, and uses the plastic film (5) instead of rapeseed oil as the lubricant. When processing the fuel tank, cut the plastic film (5) with a thickness in the range of 0.01 to 0.015mm into pieces according to the size of the fuel tank blank (4), dip a little water on the fuel tank blank (4), and then put the plastic film (5) Cover the fuel tank blank (4), put the side with the film facing the direction of the die (2) into the mold for deep drawing, if it needs to be drawn twice, after the first drawing, it is not necessary to put the plastic film (5 ) is peeled off, and the second deep drawing can be done by pulling it tightly, without another layer of film. In this way, the direct contact between the fuel tank blank (4) and the mold is avoided during deep drawing, the drawing marks formed by friction during the deep drawing process are eliminated, and the wear of the mold is also avoided, which greatly reduces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com