Automatic steam curing device and method for cement linings of nodular cast iron pipes

A technology of nodular cast iron pipe and cement lining, which is applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as unstable steam pressure, large temperature deviation of health care furnace, affecting output and quality, and improve health care Improve quality, reduce labor intensity, and realize the effect of fully automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment the present invention is described in further detail:

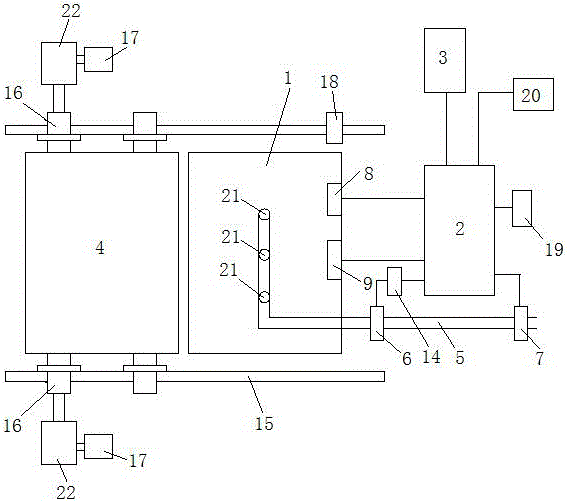

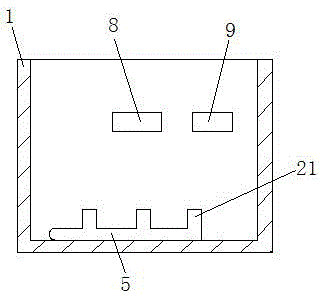

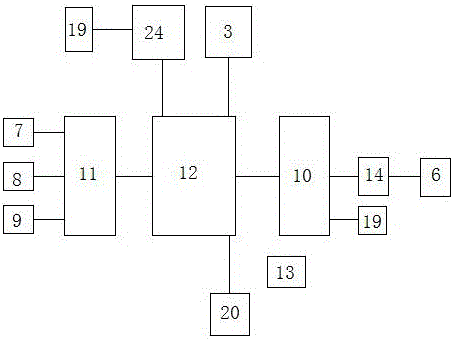

[0037] Such as figure 1 , 2As shown in and 3, a cement-lined automatic steam curing device for ductile iron pipes includes a curing furnace 1, a control cabinet 2 and an operation box 3 including a man-machine interface, and the upper edge of the steam pipeline 5 that delivers steam to the curing furnace 1 A pressure sensor 7 and an electric control valve 6 are arranged sequentially along the delivery direction of the steam. The steam pipeline 5 leading to the health furnace 1 is designed with a plurality of steam outlets 21, and each steam outlet 21 is uniformly distributed on the inner bottom surface of the health furnace 1. The steam is ventilated evenly, which ensures that the temperature and humidity in the health curing furnace 1 are increased or decreased synchronously as much as possible, and that the quality of the cement lining of each ductile iron pipe is consistent....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com