Method for processing polyurethane (PU) synthetic leather wastewater

A synthetic leather and polyurethane technology, applied in natural water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of low efficiency of anaerobic biological treatment, achieve low removal efficiency and improve biodegradability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

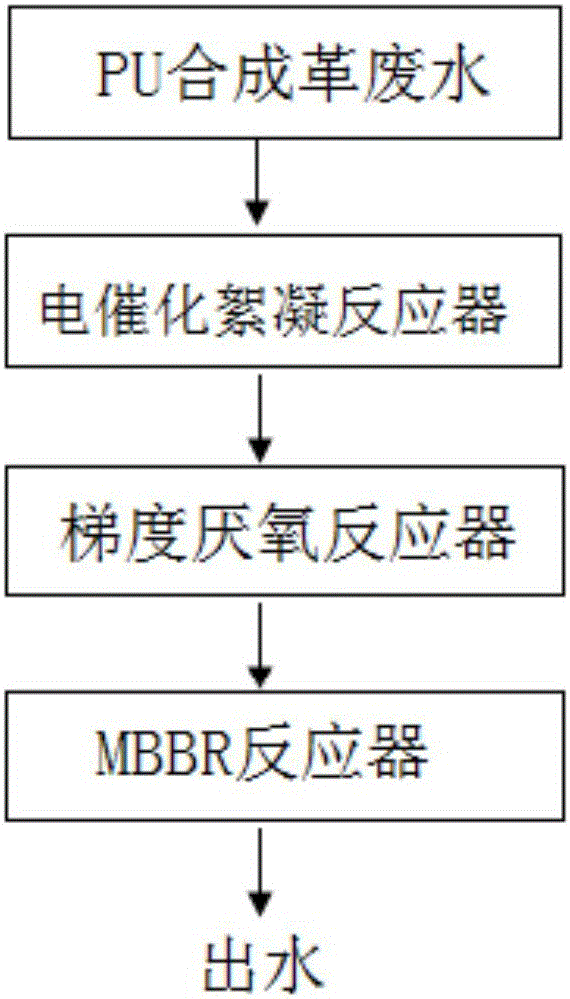

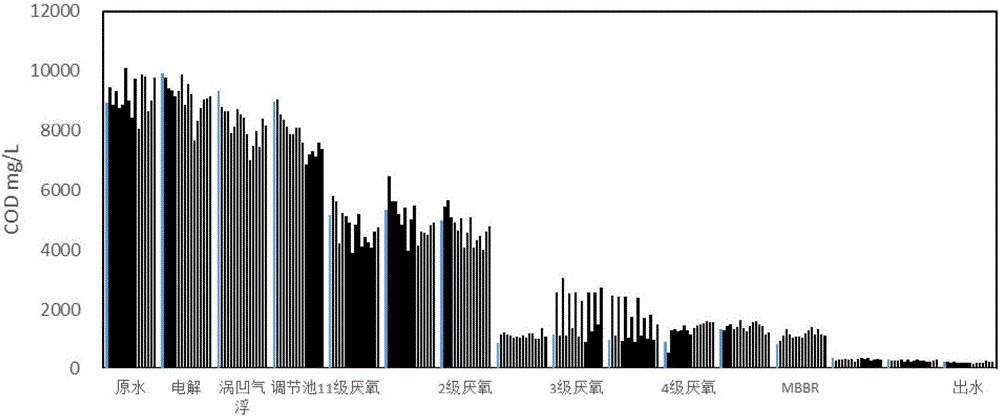

[0036] Such as figure 1 As shown, this embodiment adopts a method for treating polyurethane (PU) synthetic leather wastewater (combined process of electrocatalytic flocculation + gradient anaerobic + MBBR) to treat PU synthetic leather wastewater of a domestic company, and achieves a better Treatment effect, the operating parameters of each unit process in the integrated process are as follows:

[0037] (1) Conduct electrocatalytic flocculation pretreatment of PU synthetic leather wastewater from a domestic company, using SnO 2 RuO 2 / Ti is the anode material, the voltage is 8V, the electrocatalytic flocculation time is 30min. After treatment, the PU synthetic leather wastewater after electrocatalytic flocculation is introduced into the wastewater conditioning tank with agitating device, and it is compared with the previous conditioning tank under the agitation and water turbulence. The intermediate wastewater achieves a balanced water quality and a stable water volume adjustment ...

Embodiment 2

[0048] In this embodiment, a method for treating PU synthetic leather wastewater (combined process of electrocatalytic flocculation + gradient anaerobic + MBBR) is used to treat PU synthetic leather wastewater of a domestic company, which achieves a better treatment effect and an integrated process The operating parameters of each unit process are as follows:

[0049] (1) Conduct electrocatalytic flocculation pretreatment of PU synthetic leather wastewater from a domestic company, using SnO 2 RuO 2 / Ti is the anode material, the voltage is 15V, and the electrocatalytic flocculation time is 5min. After treatment, the synthetic leather wastewater after electrocatalytic flocculation is introduced into the wastewater regulating tank with agitating device;

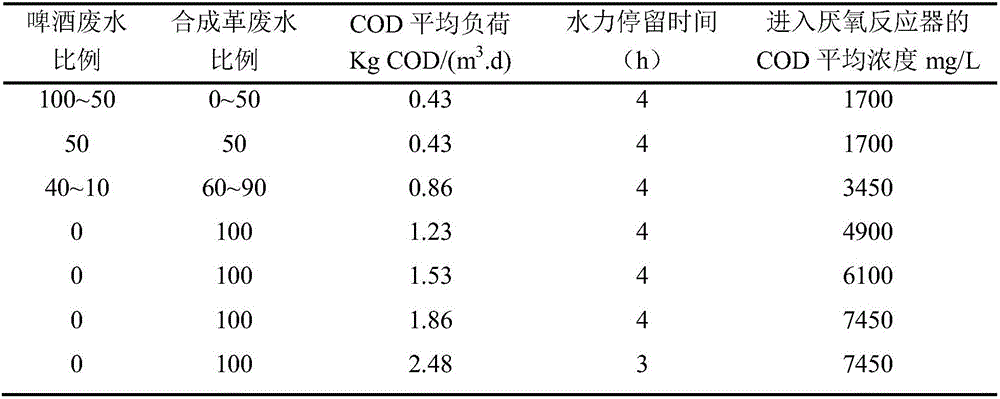

[0050] (2) Use a pump to pump the waste water in the regulating tank in step (1) into the gradient anaerobic reactor. The gradient anaerobic reactor is an integrated anaerobic reactor with four-stage partitions, and its average organ...

Embodiment 3

[0057] In this embodiment, a method for treating PU synthetic leather wastewater (combined process of electrocatalytic flocculation + gradient anaerobic + MBBR) is used to treat PU synthetic leather wastewater of a domestic company, which achieves a better treatment effect and an integrated process The operating parameters of each unit process are as follows:

[0058] (1) Conduct electrocatalytic flocculation pretreatment of PU synthetic leather wastewater from a domestic company, using SnO 2 RuO 2 / Ti is the anode material, the voltage is 12V, and the electrocatalytic flocculation time is 25min. After treatment, the synthetic leather wastewater after electrocatalytic flocculation is introduced into the wastewater regulating tank with agitating device;

[0059] (2) Use a pump to pump the wastewater in the regulating tank in step (1) into the gradient anaerobic reactor. The gradient anaerobic reactor is an integrated anaerobic reactor with 4 levels of partitions, and its average orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com