Method for chemical vapor reaction deposition of transparent hydrophobic easy-to-clean thin film

A chemical gas phase reaction, easy-to-clean technology, applied in the direction of coating, etc., can solve the problems that are not suitable for industrial mass production, high cost, slow deposition rate, etc., and achieve good promotion and application prospects, reduce production costs, and fast deposition speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

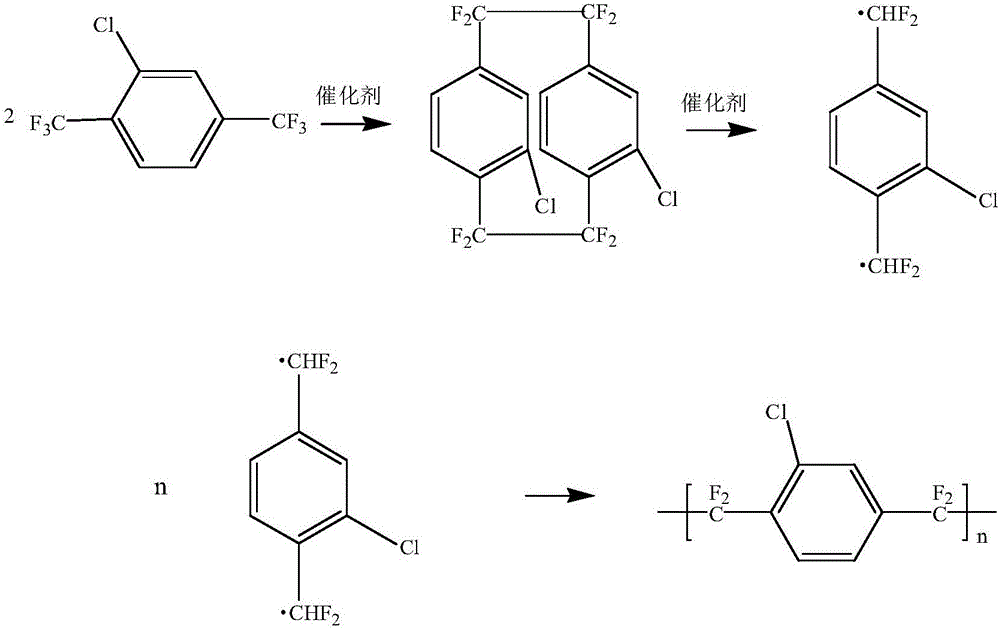

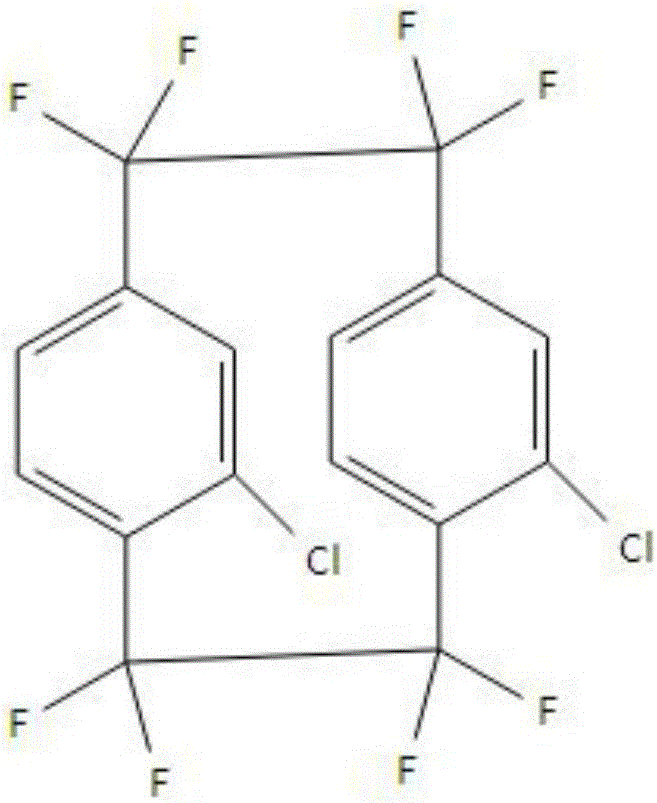

[0032] The raw material is 6-fluorine-1-chloro-p-xylene as raw material. First, mix trimethylchlorosilane with nano-magnesium powder or magnesium fluoride, pour it into N,N-dimethylformamide, and then mix 6-fluoro-1-chlorine P-xylene was added dropwise, stirred magnetically at room temperature under an argon atmosphere for 20 minutes to react, then terminated the reaction by adding deionized water, extracted with hexane, dehydrated with anhydrous magnesium sulfate, and then obtained by suction filtration Colorless and transparent solution 5 fluorine 1 chlorosilane p-xylene.

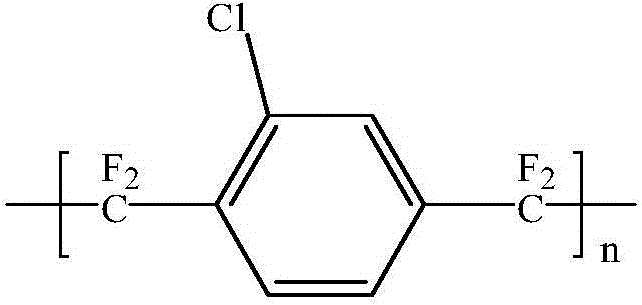

[0033] Use the precursor synthesized in the first step to carry out the second catalytic reaction, using cesium fluoride as the catalyst, mix the precursor of the first step with cesium fluoride and pour it into anisole, and then heat the liquid to 160 degrees Celsius to carry out After condensing and refluxing for 24 hours, the cooled mixed liquid was subjected to suction filtration, and the filtered liq...

Embodiment 2

[0037] The raw material is 6-fluoro-1 chloro-p-xylene as the source material. Firstly, after mixing trimethylchlorosilane with nano-magnesium powder or magnesium fluoride, it is poured into N,N-dimethylformamide, and then 6-fluoro-1 Chloro-p-xylene was added dropwise, and the reaction was carried out under argon atmosphere with magnetic stirring at room temperature for 30 minutes, and then the reaction was terminated by adding deionized water, extracted with hexane, dehydrated with anhydrous magnesium sulfate, and then suction filtered A colorless and transparent solution of 5-fluoro-1-chlorosilyl-p-xylene was obtained.

[0038] Use the precursor synthesized in the first step to carry out the second catalytic reaction, using cesium fluoride as the catalyst, mix the precursor of the first step with cesium fluoride and pour it into anisole, and then heat the liquid to 160 degrees Celsius to carry out After condensing and refluxing for 24 hours, the cooled mixed liquid was subjec...

Embodiment 3

[0042]The raw material is 6-fluoro-1 chloro-p-xylene as the source material. Firstly, after mixing trimethylchlorosilane with nano-magnesium powder or magnesium fluoride, it is poured into N,N-dimethylformamide, and then 6-fluoro-1 Chloro-p-xylene was added dropwise, and the reaction was carried out under argon atmosphere with magnetic stirring at room temperature for 25 minutes, and then the reaction was terminated by adding deionized water, extracted with hexane, dehydrated with anhydrous magnesium sulfate, and then suction filtered A colorless and transparent solution of 5-fluoro-1-chlorosilyl-p-xylene was obtained.

[0043] Use the precursor synthesized in the first step to carry out the second catalytic reaction, using cesium fluoride as the catalyst, mix the precursor of the first step with cesium fluoride and pour it into anisole, and then heat the liquid to 160 degrees Celsius to carry out After condensing and refluxing for 24 hours, the cooled mixed liquid was subject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com