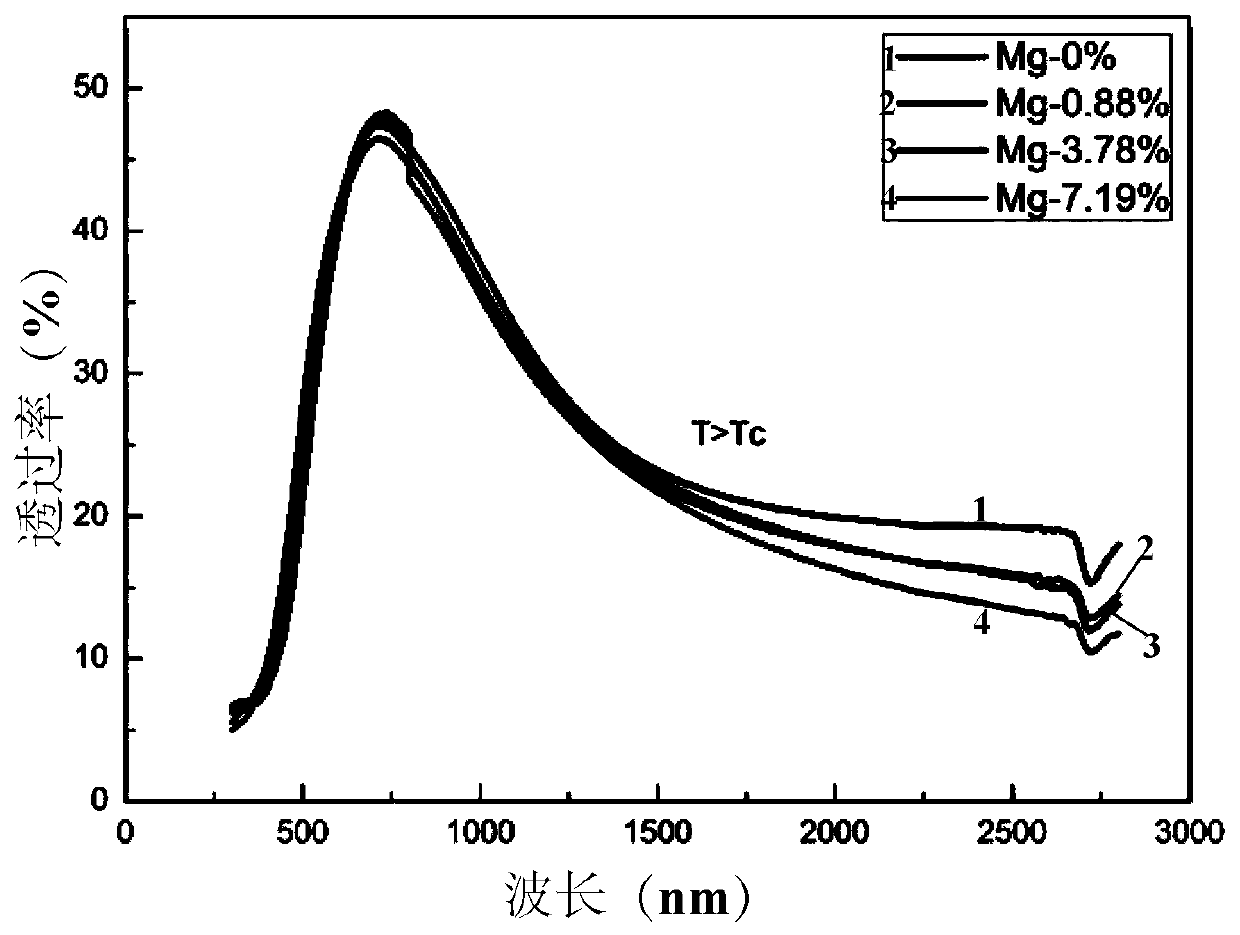

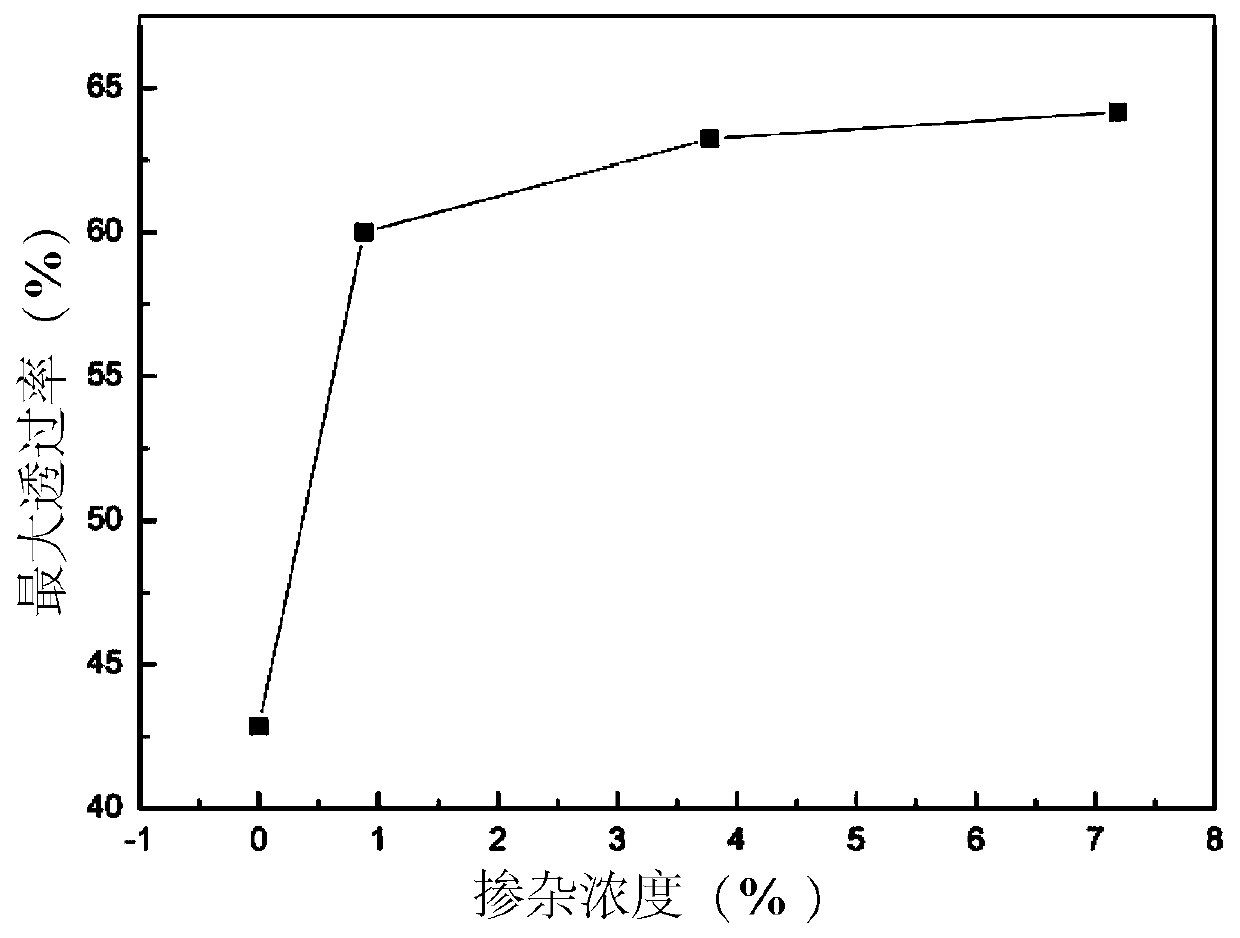

A kind of metal element Mg doped VO2 thin film and preparation method thereof

A metal element, VO2 technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of reduced light modulation ability, reduced film transmittance, and widened thermal hysteresis loop , to achieve the effects of enhanced light modulation ability, reduced density, and enhanced modulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

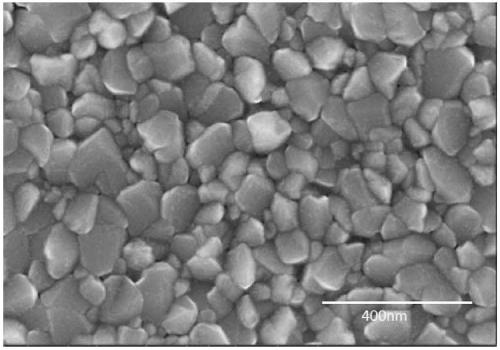

[0035] The coating equipment that the present invention adopts is the MSP-3200 three target co-sputter coating machine that Beijing Chuangshi Weina Science and Technology Co., Ltd. assembles, is base with quartz glass, metal vanadium target is radio frequency target, metal magnesium target is direct current target, oxygen ( 99.99%), the reaction gas is feedback controlled by the plasma emission spectrometer monitoring system (PEM), argon is the working gas (99.99%), the background vacuum value is -5 Pa, the RF power is 300W, the DC power is 25W, 30W and 40W respectively, the working pressure is 0.5 Pa, and the quartz substrate is heated to 470°C;

[0036] The steps of the inventive method are illustrated below:

[0037] 1) Put the quartz sheet on the graphite plate and send it into the reaction chamber; 2) Vacuum the reaction chamber to a vacuum degree 2 The thin film is tested by the V-VASE ellipsometer of J.A.Woollam Company in the United States, and the VO is obtained by mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com