A kind of low-grade diatom original earth purification and enrichment process

A purification, enrichment, and low-grade technology, which is applied in the direction of cyclone devices, grain processing, etc., can solve the problems of long process flow, low mechanization level, and many workers, and achieve simplified process flow, high cost-effective equipment, and short process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

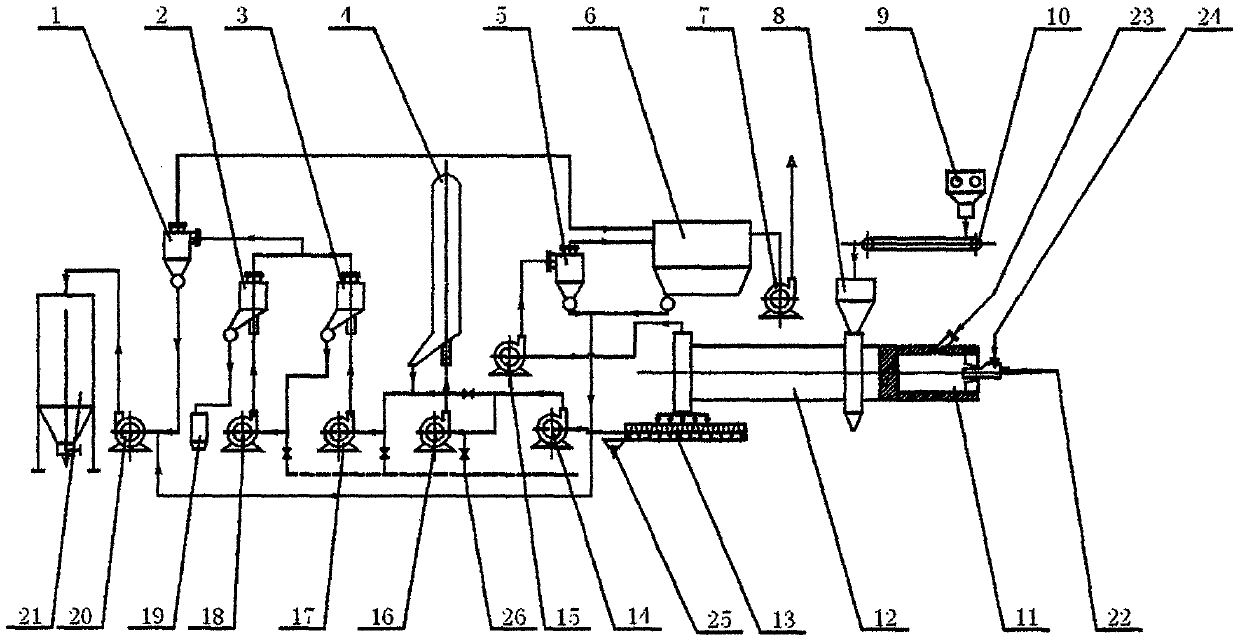

[0022] In the embodiment of the present invention, the purification and enrichment process of low-grade diatom raw soil adopts dry method purification technology, and utilizes a dry method production device composed of various process equipment with different technical characteristics to process low-grade diatom raw soil or Purification and enrichment of non-metallic mineral resources with similar physical and chemical properties; the process consists of raw material pretreatment process, material drying and crushing process and material classification process;

[0023] (1) The raw material pretreatment process is equipped with a powerful disintegrator 9 with a rotating speed of 4 to 30 r / min, which has the function of automatically returning unbreakable stones, a gas hot blast stove 11 with coal gas as fuel, and a gas hot blast stove 11 A horizontal rotary dryer 12 connected to extract hot air, and a vibrating screen 13;

[0024] (2) The material drying and crushing process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com