Treatment process for high-concentration liquid crystal wastewater

A treatment process, high-concentration technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of lack of mature and effective treatment methods, difficult treatment, difficult microorganisms Degradation and other problems, to achieve good application prospects, ensure water quality safety, improve the effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for treating high-concentration liquid crystal wastewater proposed by the present invention will be described below in conjunction with specific embodiments.

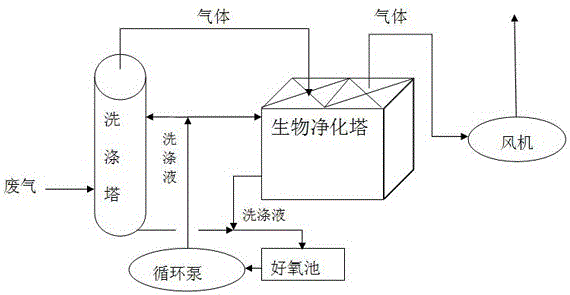

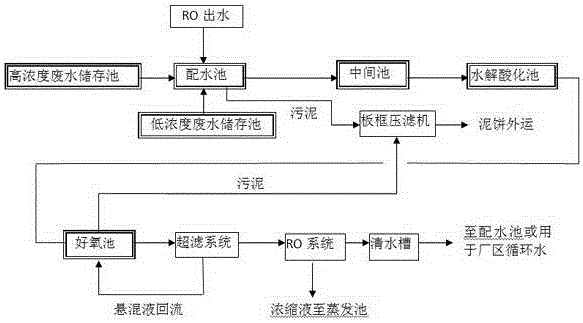

[0023] See attached figure 1 And attached figure 2 , waste gas treatment in waste water and treatment process of the present invention. Among them, the wastewater treatment part includes four sections: pretreatment, biochemical treatment, membrane advanced treatment and enhanced evaporation treatment of membrane dope. There is no wastewater discharge in the whole process, and internal recycling is realized; waste gas treatment includes two spraying and biological purification towers. part.

[0024] The present invention specifically comprises the following steps:

[0025] 1) Pretreatment: Fenton + catalytic oxidation technology is used to pretreat the wastewater to improve the B / C of the wastewater, and the pretreatment is carried out in the distribution tank.

[0026] In the present invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com