Fiber-reinforced modified expanded perlite thermal insulation board and production method thereof

An expanded perlite and fiber-reinforced technology, which is applied in the field of building materials, can solve problems such as application limitations of expanded perlite insulation boards, and achieve the effects of superior fire resistance, high strength, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

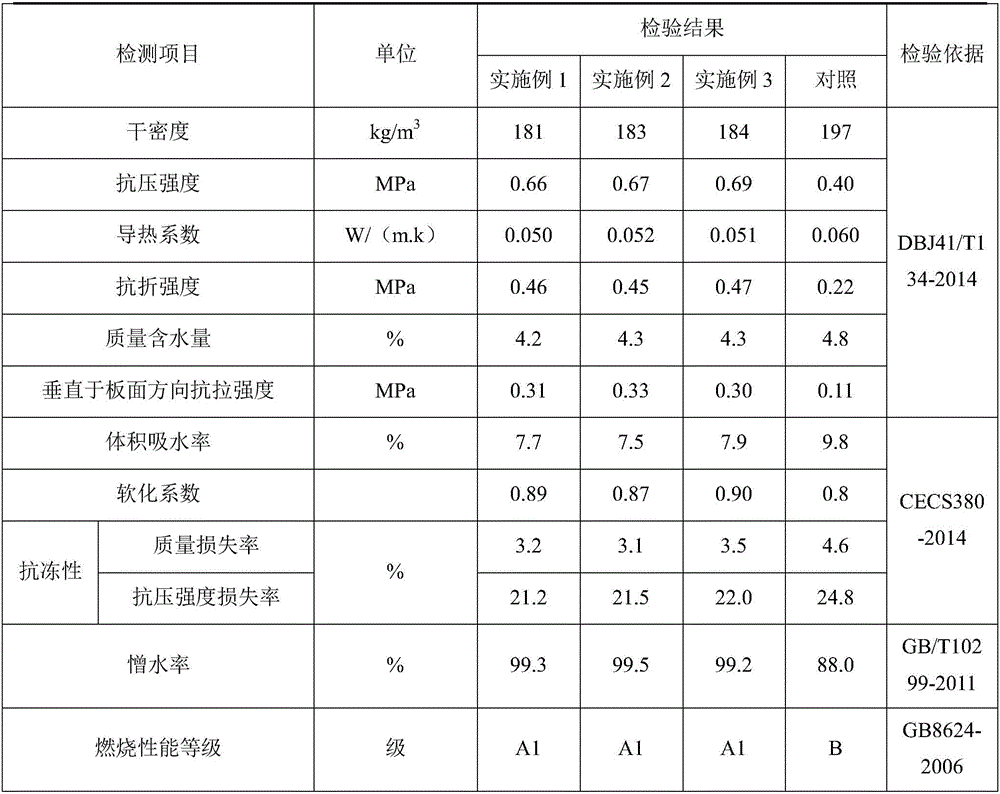

Embodiment 1

[0040] The fiber-reinforced modified expanded perlite insulation board of this embodiment includes the following components in parts by weight: 20 parts of cement, 5 parts of fly ash, 5 parts of propyltrimethoxysilane, 10 parts of polyacrylate emulsion, 50 parts of modified expanded perlite, 2 parts of sodium dodecylbenzenesulfonate, 8 parts of additives, 0.3 parts of PP fiber, 0.5 part of hydroxypropyl methylcellulose, 3 parts of zirconia fiber, 3 parts of carbon fiber and 10 parts of water share.

[0041] The additive includes the following components in parts by weight: 30 parts of calcium sulfate, 5 parts of aluminum oxide, 3 parts of triethanolamine, 10 parts of zinc phosphate and 15 parts of iron oxide.

[0042] The specific preparation method of the modified expanded perlite is: heating the perlite to 1000°C for puffing treatment, expanding the volume of the perlite by 7 times to obtain the expanded perlite, and then cooling down, when the temperature drops to 150°C, th...

Embodiment 2

[0049] The fiber-reinforced modified expanded perlite insulation board of this embodiment includes the following components in parts by weight: 18 parts of cement, 8 parts of fly ash, 2 parts of propyltrimethoxysilane, 5 parts of polyacrylate emulsion, 60 parts of modified expanded perlite, 0.7 parts of sodium dodecylbenzenesulfonate, 5 parts of additives, 0.1 part of PP fiber, 2 parts of hydroxypropyl methylcellulose, 4 parts of zirconia fiber, 2 parts of carbon fiber and 15 parts of water share.

[0050] The additives include the following components in parts by weight: 25 parts of calcium sulfate, 3 parts of aluminum oxide, 0.2 parts of triethanolamine, 5 parts of zinc phosphate and 20 parts of iron oxide.

[0051] The specific preparation method of the modified expanded perlite is as follows: heating the perlite to 1300°C for puffing treatment, expanding the volume of the perlite by 10 times to obtain the expanded perlite, and then cooling down, when the temperature drops ...

Embodiment 3

[0058] The fiber-reinforced modified expanded perlite insulation board of this embodiment includes the following components in parts by weight: 25 parts of cement, 6 parts of fly ash, 4 parts of propyltrimethoxysilane, 8 parts of polyacrylate emulsion, 70 parts of modified expanded perlite, 2.9 parts of sodium dodecylbenzenesulfonate, 10 parts of additives, 0.5 parts of PP fiber, 1 part of hydroxypropyl methylcellulose, 5 parts of zirconia fiber, 1 part of carbon fiber and 20 parts of water share.

[0059] The additive includes the following components in parts by weight: 35 parts of calcium sulfate, 2 parts of aluminum oxide, 5 parts of triethanolamine, 8 parts of zinc phosphate and 16 parts of iron oxide.

[0060] The specific preparation method of the modified expanded perlite is: heating the perlite to 1200°C for puffing treatment, expanding the volume of the perlite by 7 times to obtain the expanded perlite, and then cooling down, when the temperature drops to 200°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com