A high-strength and low-shrinkage anti-crack pavement base material

A pavement base material and low-shrinkage technology, applied in the field of building materials, can solve the problems of shortage of road construction resources, large shrinkage cracks, small shrinkage coefficient, etc., achieve high bonding strength, overcome dry shrinkage, and reduce water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

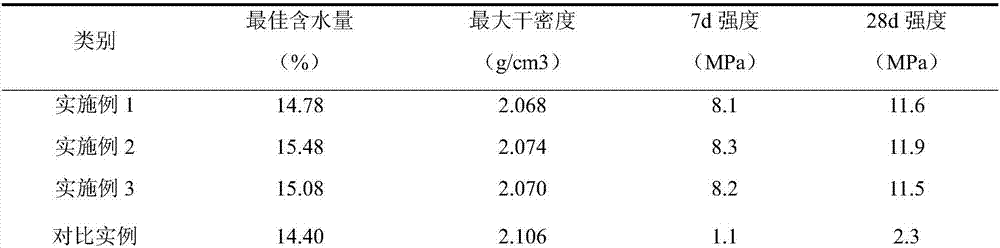

[0040] A high-strength, low-shrinkage anti-crack pavement base material, which is compounded by cement, steel slag sand, fine-grained soil and admixtures in a mass ratio of 6:20:72:2, wherein the components in the admixtures and their The mass percentage is: 5% of dihydrate gypsum, 2% of sodium metasilicate nonahydrate, 1% of water stability enhancer, 20% of mineral powder, 25% of calcium chloride, 25% of magnesium oxide, and 22% of slaked lime; The preparation method of high-strength and low-shrinkage anti-crack pavement base material is as follows:

[0041] According to the "Test Regulations for Highway Engineering Inorganic Binder Stable Materials" (JTG E51-2009), the optimum water content of the above raw materials is 14.78%, and the maximum dry density is 2.068g / cm 3 ; Take steel slag sand and fine-grained soil according to the weight ratio of each component, mix the two, and add 3% less water than the optimum water content, and keep the stuffing for no less than 10 hours...

Embodiment 2

[0048] A high-strength, low-shrinkage anti-crack pavement base material, which is compounded by cement, steel slag sand, fine-grained soil and admixture at a mass ratio of 6:40:51:3, wherein the components in the admixture and their The mass percentage is: 5% of dihydrate gypsum, 5% of sodium metasilicate nonahydrate, 2% of water stability enhancer, 15% of mineral powder, 28% of calcium chloride, 20% of magnesium oxide, and 25% of slaked lime.

[0049] According to the "Test Regulations for Highway Engineering Inorganic Binder Stable Materials" (JTG E51-2009), the optimum water content of the above raw materials is 15.48%, and the maximum dry density is 2.074g / cm 3 ; Take steel slag sand and fine-grained soil according to the weight ratio of each component, mix the two, and add 3% less water than the optimum water content, and keep the stuffing for no less than 10 hours; Water gypsum, sodium metasilicate nonahydrate, calcium chloride, magnesium oxide, mineral powder, slaked li...

Embodiment 3

[0054] A high-strength, low-shrinkage anti-crack pavement base material, which is compounded by cement, steel slag sand, fine-grained soil and admixture at a mass ratio of 6:10:80:4, wherein the components in the admixture and their The mass percentage is: 5% of dihydrate gypsum, 4% of sodium metasilicate nonahydrate, 2% of water stability enhancer, 20% of mineral powder, 15% of calcium chloride, 29% of magnesium oxide, and 25% of slaked lime.

[0055] According to the "Test Regulations for Highway Engineering Inorganic Binder Stable Materials" (JTG E51-2009), the optimum water content of the above raw materials is 15.08%, and the maximum dry density is 2.070g / cm 3 ; Take steel slag sand and fine-grained soil according to the weight ratio of each component, mix the two, and add 3% less water than the optimum water content, and keep the stuffing for no less than 10 hours; Water gypsum, sodium metasilicate nonahydrate, calcium chloride, magnesium oxide, mineral powder, slaked li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com