Flexible anti-cracking protective mortar and preparation method thereof

A kind of mortar and flexible technology, which is applied in the field of mortar and flexible anti-cracking protective mortar, can solve the problems that restrict the promotion and application of new wall materials, shrinkage and cracking of building walls, leakage and water seepage, etc., and achieve easy control of product quality and excellent construction performance , the effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The components of the flexible anti-crack protective mortar in this embodiment are: Ordinary Portland cement: 30.55, Quartz sand: 58, Slaked lime: 5, Anti-crack fiber: 4.2, Redispersible latex powder: 1.5, Cellulose ether: 0.3, plastic expansion agent: 0.05, water-repellent agent: 0.4. Among them, quartz sand is prepared from 30-50 mesh, 40-70 mesh, and 70-100 mesh according to the ratio of 2:4:1 by weight; the anti-cracking fiber is made of lignin fiber with a fiber length ≤ 3mm, and its function is to impart flexibility. Anti-crack protective mortar has better crack resistance and flexibility; redispersible latex powder is ethylene-vinyl acetate latex powder; cellulose ether is hydroxyethyl methyl cellulose with a viscosity of 6000mPa.s-45000mPa.s; plasticity The swelling agent is a powdery modified organic acid salt-based plastic swelling agent; the water-repellent agent is a silicone-type water-repellent agent.

[0026] During preparation, after weighing the compon...

Embodiment 2

[0029] The components by weight of the flexible anti-crack protective mortar of this embodiment are: Ordinary Portland cement: 40, Quartz sand: 48, Slaked lime: 6, Anti-crack fiber: 3.2, Redispersible latex powder: 2, Cellulose ether: 0.2, plastic expansion agent: 0.15, water-repellent agent: 0.45. Among them, quartz sand is prepared from 30-50 mesh, 40-70 mesh, 70-100 mesh according to the ratio of 3:6:3 by weight; the anti-cracking fiber is lignin fiber with a fiber length of about 2mm; redispersible latex The powder is ethylene-vinyl chloride-vinyl laurate latex powder; the cellulose ether is hydroxypropyl methylcellulose with a viscosity of 6000mPa.s-45000mPa.s; the plastic expansion agent is a powdery modified organic acid salt-based plastic expansion agent agent; water-repellent agent is a osmotic crystalline material. The preparation method is basically the same as that of Example 1, and will not be described in detail.

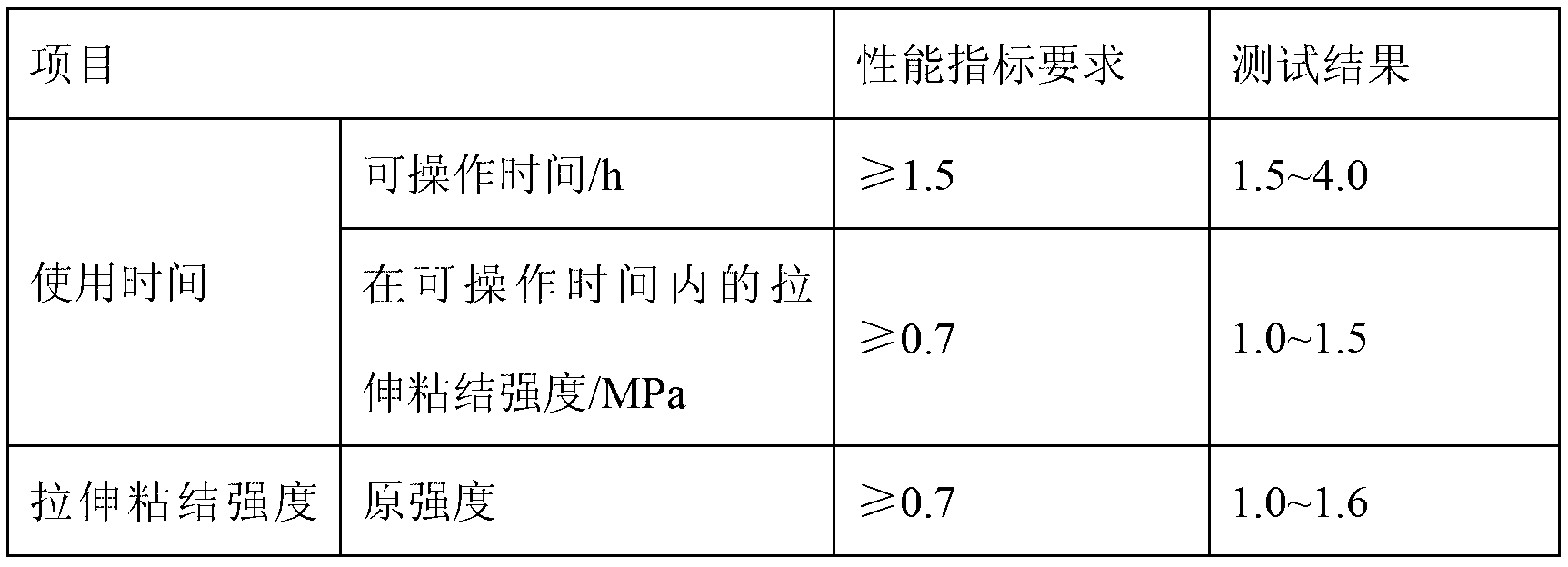

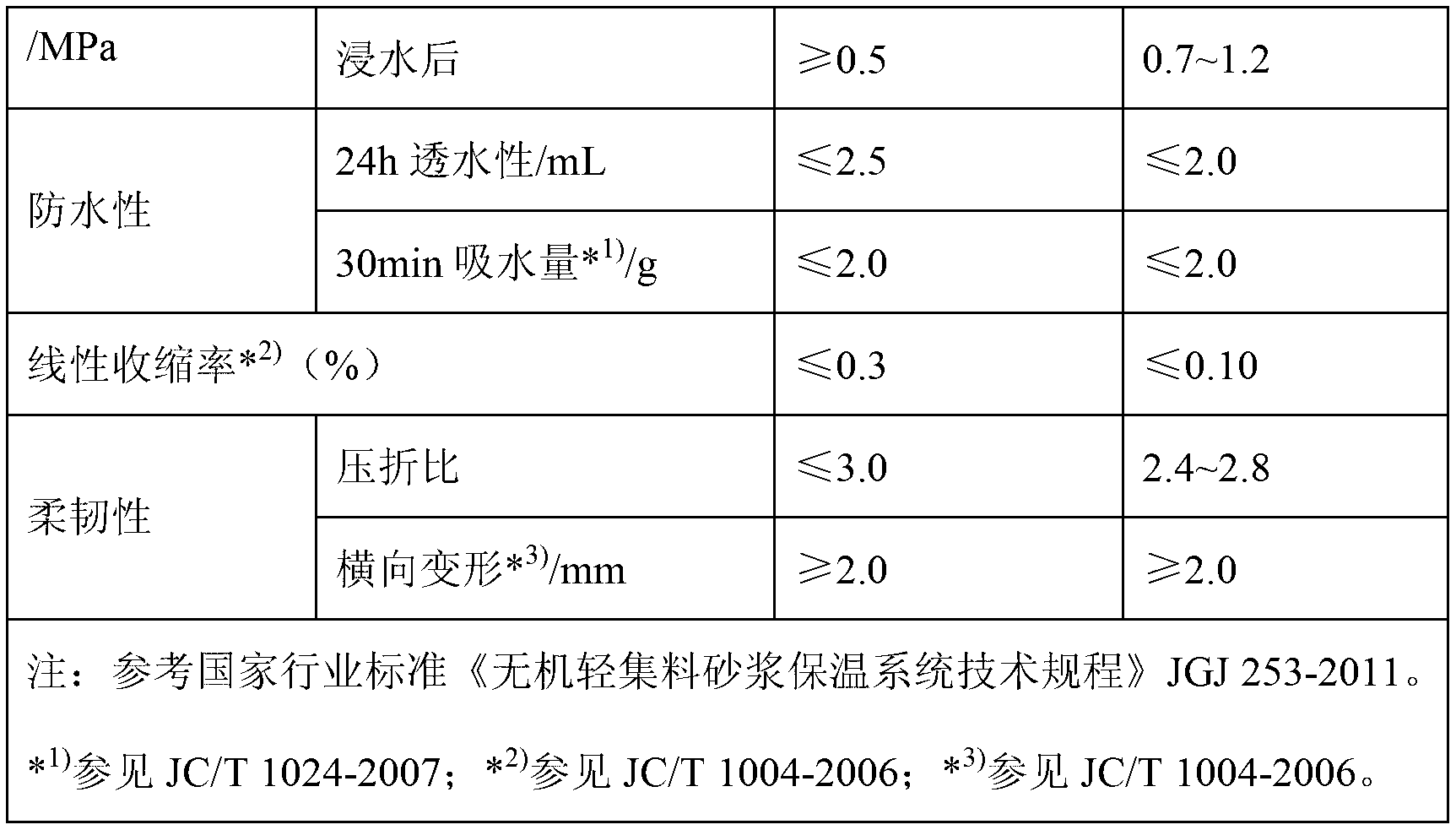

[0030] The performance obtained by the test si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com