A production process of Shanluodong Tibetan rice wine

A production process and hole storage technology, which is applied in the field of rice wine, can solve the problems affecting the flavor and quality of wine, and achieve the effects of improving mellowness and taste, high quality and stability, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

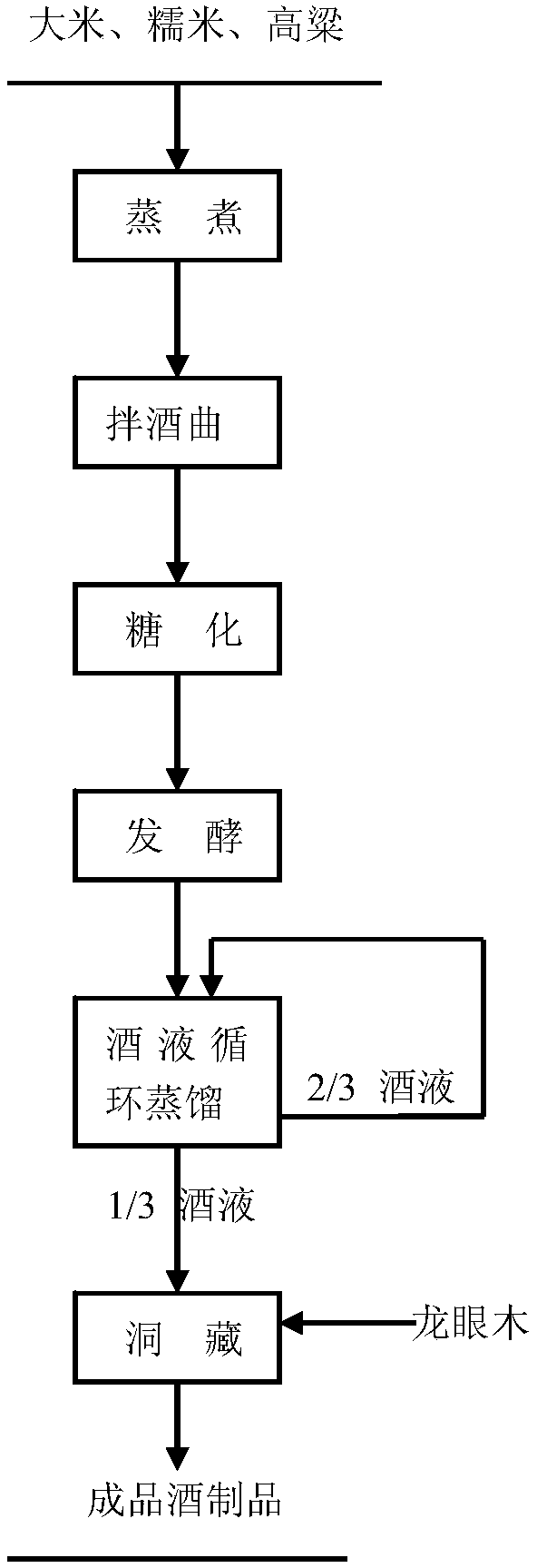

Method used

Image

Examples

Embodiment 1

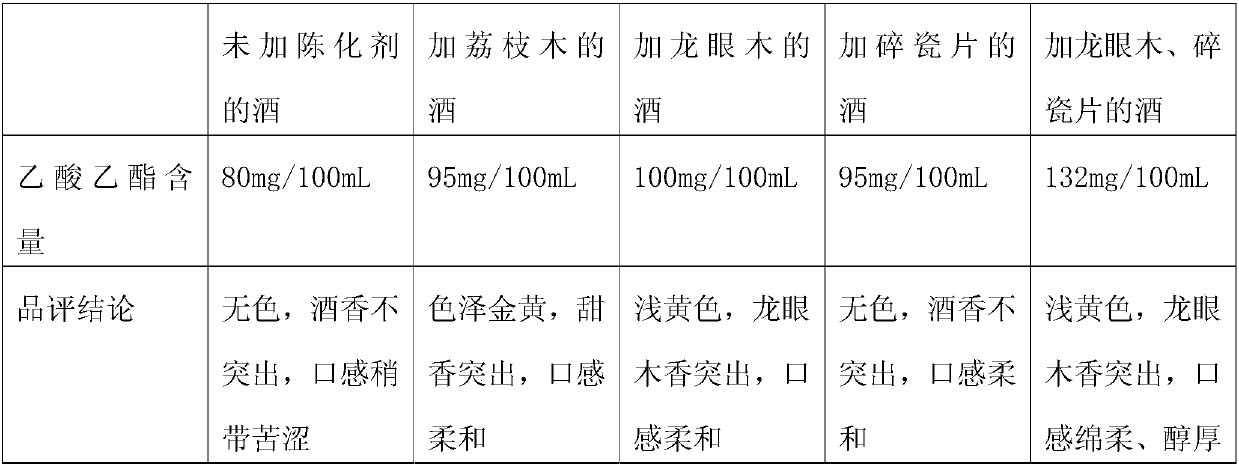

[0036] The raw material is 210 jin of local 903 rice, 60 jin of white glutinous rice, and 30 jin of Sichuan glutinous sorghum, mixed, crushed, passed through a 20-mesh sieve, and then placed in water at a temperature of 50°C for 12 hours, then dried to make the raw material The moisture content of the material reaches 20%, and finally the material is matured after cooking in the boiler for 40 minutes. Stir the cooked clinker evenly, put it in a large basin, spread it out, and after cooling to 38°C, activate 0.9 kg of distiller's yeast with warm water, add it to the clinker, and stir so that the two can be mixed evenly, then Put the clinker mixed with distiller's yeast in a pot and keep it at 30°C. After sealing it, pile it up for 18 hours to get the saccharified clinker. Put the saccharified clinker into a pottery jar, add 450 jin of water, and then use The 10% acetic acid solution diluted with glacial acetic acid adjusts the pH value to 4.5 and controls the temperature at 35°...

Embodiment 2

[0038] The raw material is 210 jin of local 903 rice, 60 jin of white glutinous rice, and 30 jin of Sichuan glutinous sorghum, mixed, crushed, passed through a 20-mesh sieve, and then placed in water at a temperature of 50°C for 12 hours, then dried to make the raw material The moisture content of the material reaches 20%, and finally the material is matured after cooking in the boiler for 40 minutes. Stir the cooked clinker evenly, put it in a large basin, spread it out, and after cooling to 38°C, activate 1.2 kg of distiller's yeast with warm water, add it to the clinker, and stir so that the two can be mixed evenly, then Put the clinker mixed with distiller's yeast in a pot and keep it at 30°C. After sealing it, pile it up for 20 hours to get the saccharified clinker. The 10% acetic acid solution diluted with glacial acetic acid adjusts the pH value to 4.5 and controls the temperature at 35°C. After sealing it, ferment it for 50 days to obtain fermented glutinous rice; Slo...

Embodiment 3

[0040] The raw material is 210 jin of local 903 rice, 60 jin of white glutinous rice, and 30 jin of Sichuan glutinous sorghum, mixed, crushed, passed through a 20-mesh sieve, and then placed in water at a temperature of 50°C for 12 hours, then dried to make the raw material The moisture content of the material reaches 20%, and finally the material is matured after cooking in the boiler for 40 minutes. Stir the cooked clinker evenly, put it in a large basin, spread it out, and after cooling to 38°C, activate 1.5 kg of distiller's yeast with warm water, add it to the clinker, and stir so that the two can be mixed evenly, then Put the clinker mixed with distiller's yeast in a pot and keep it at 30°C. After sealing it, pile it up for 22 hours to get the saccharified clinker. Put the saccharified clinker into a ceramic jar, add 450 jin of water, and The 10% acetic acid solution diluted with glacial acetic acid adjusts the pH value to 4.5 and controls the temperature at 35°C. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com