Brazil cherry wine and preparation method thereof

A technology of cherry wine and cherry fruit, applied in the field of Brazilian cherry wine and its production, can solve the problems of restricting the promotion and popularization of Brazilian cherry and larger development and application fields, singleness, etc., and achieve attractive color, good taste and clear wine quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

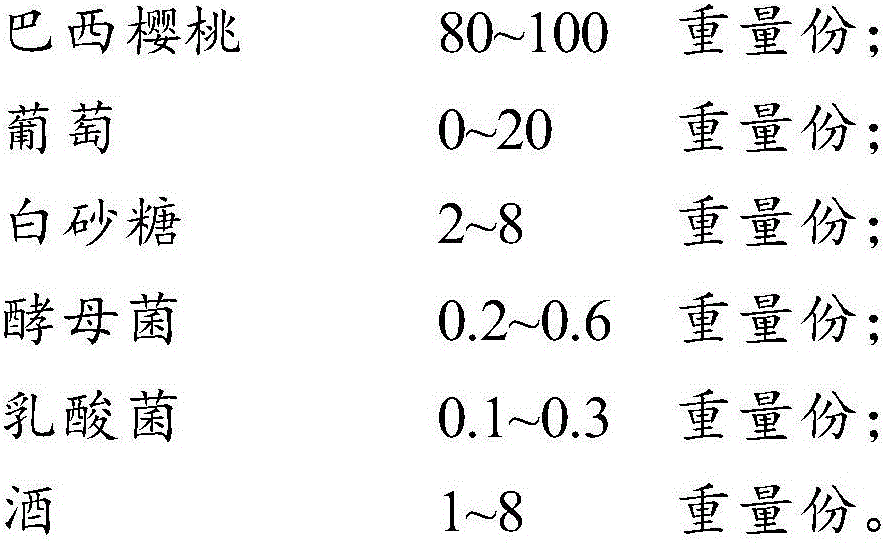

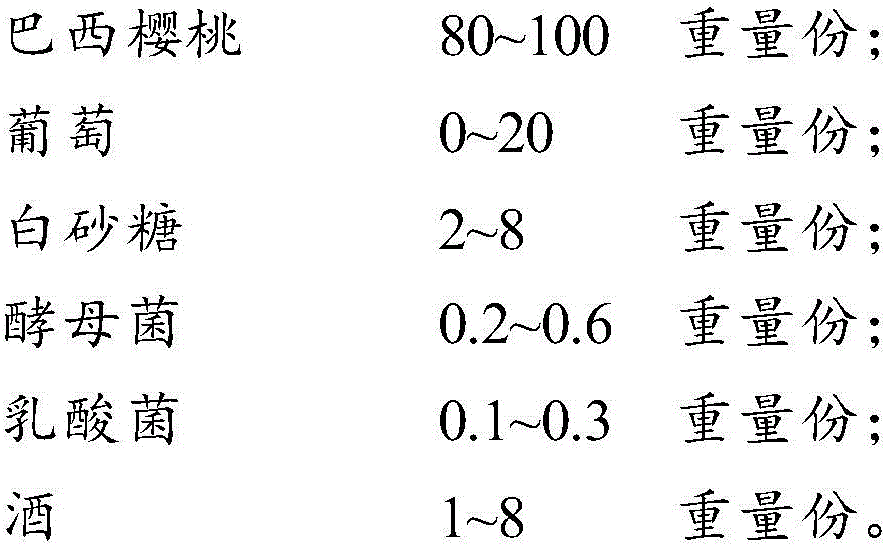

Method used

Image

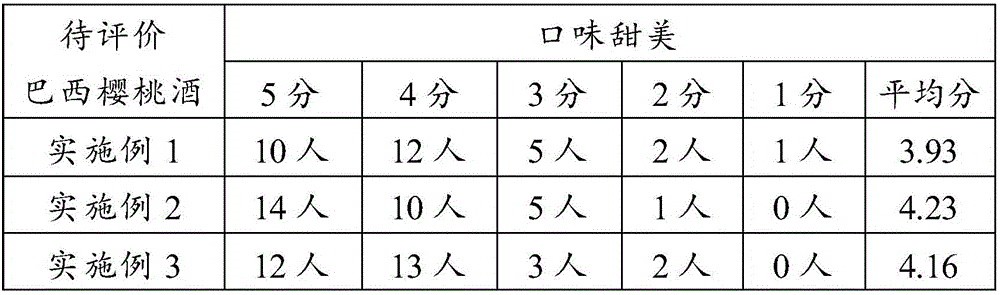

Examples

preparation example Construction

[0037] The present invention also provides a kind of preparation method of Brazilian cherry wine, comprises the following steps:

[0038] A) breaking the fruit, then mixing it with yeast and lactic acid bacteria, and then filtering to obtain a fermented sauce;

[0039] Described fruit is the mixture of Brazilian cherry fruit and grape or Brazilian cherry fruit;

[0040] B) adding sugar and wine after sterilizing the fermented sauce obtained in the above steps to obtain wine syrup;

[0041] C) After homogenizing and filtering again, the liquor syrup obtained in the above steps is obtained to obtain Brazilian cherry wine.

[0042] In the above preparation method of the present invention, the selection range and optimization principle of the raw materials are consistent with the selection range and optimization principle of the aforementioned brazilian cherry wine, and will not be repeated here.

[0043] In the invention, the fruit is first crushed, mixed with yeast and lactic ...

Embodiment 1

[0056] Select 100Kg of Brazilian cherry fruit with plump fruit, no damage by diseases and insect pests, and no rot, wash it with clean water, drain it, and crush it with a beater. Take out the peel and core, grind them with a colloid mill, add them to the fruit juice, mix them evenly, put them in a fermenter for fermentation, add 0.4 kg of yeast and 0.2 kg of lactic acid bacteria, and ferment at 28 degrees for 63 days. Pour out the tank once every 7 days and filter with 100 mesh. The filtered sauce continues to ferment, and after 25 days, it is sterilized by an instant sterilizer at 121 degrees. After sterilization, white granulated sugar is added to make the sweetness of the liquor reach 14 degrees, and white wine is added to make the liquor degree reach 12 degrees. Then use a homogenizer to homogenize, and filter again with a paper filter and a PE sintered filter element to make the wine quality reach 0.5 micron and the texture is clear.

Embodiment 2

[0058] Select 80 kg of Brazilian cherry fruit and 20 kg of grapes with plump fruit, no pests and diseases, and no rot, wash them with clean water, drain them, and crush them with a beater. Take out the peel and core, grind them with a colloid mill, add them to the fruit juice, mix them evenly, put them in a fermenter for fermentation, add 0.3kg of yeast and 0.2kg of lactic acid bacteria, ferment at 27 degrees, and ferment for 63 days. Pour out the tank once every 7 days, and then filter with 90 mesh. The filtered sauce continues to ferment, and after 28 days, it is sterilized with an instant sterilizer at 121 degrees. Add white granulated sugar after sterilization, make the sweetness of wine liquid reach 12 degrees, add white wine, make wine degree reach 10 degrees. Then use a homogenizer to homogenize, and then filter with a paper filter and a PE sintered filter element filter to make the wine quality reach 1 micron and the wine quality is clear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com