Anti-electrostatic modified PBT fiber

An antistatic and modified technology, applied in the field of fibers, can solve problems such as limiting the application field of polyester fibers, and achieve the effects of improving mechanical strength, easy operation, and reducing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

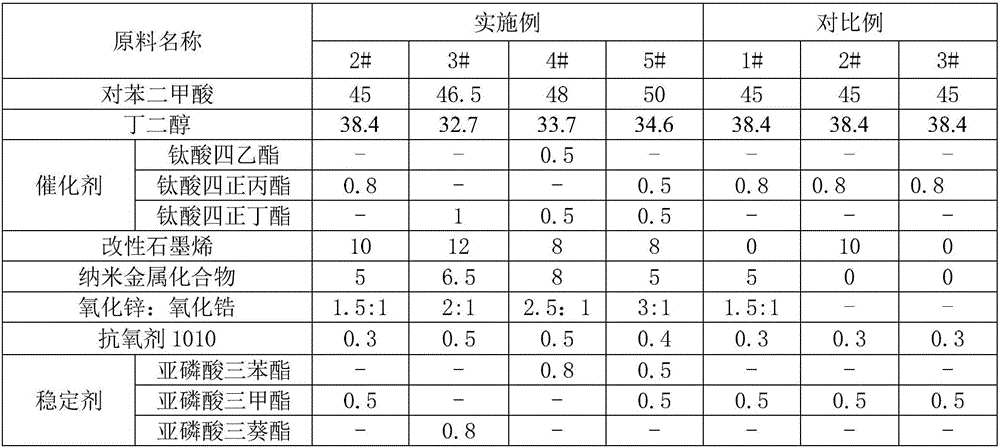

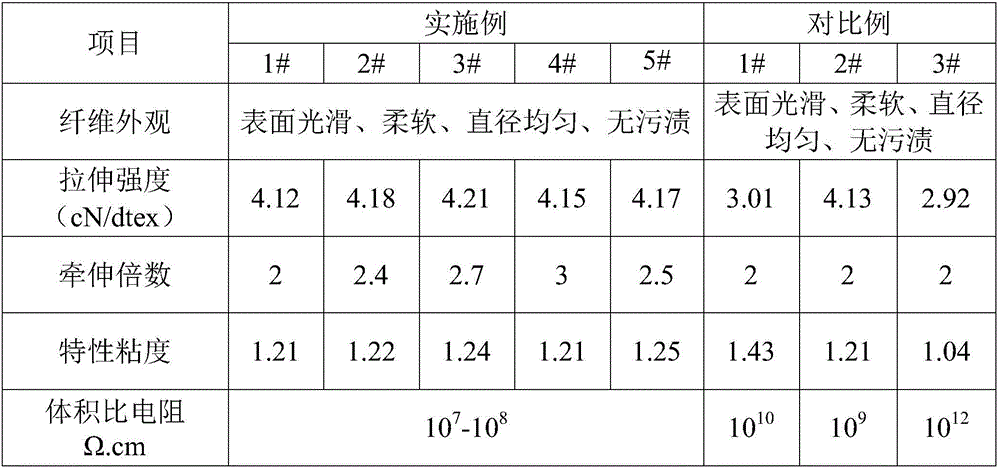

[0018] A kind of antistatic modified PBT fiber is made of components comprising the following parts by mass:

[0019] 45 parts of terephthalic acid, 43 parts of butanediol, 0.5 parts of tetraethyl titanate, 8 parts of modified graphene, zinc oxide and zirconium oxide with a particle size of 50-100nm in a mass ratio of 1:1. 3 parts of compound, 0.1 part of antioxidant 1010, 0.4 part of triphenyl phosphite.

[0020] Wherein, the modified graphene is prepared as follows: 1) Graphene vulcanization: immerse graphene in concentrated sulfuric acid, heat at a temperature of 140-150°C for 10-12h, take out and wash with distilled water for 3-6 times to obtain vulcanization Graphene; (2) sulfide graphene is dissolved in dehydrated alcohol solvent, and the concentration in the sulfide graphene dehydrated alcohol is 3~5%, and ethanol solvent pH control is 8.5, then adds silane coupling agent KH550, at temperature The reaction is carried out at 35-45° C. for 3-5 hours; (3) centrifugation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com