Chemical modification method of lamprophyre in thick coal seam by horizontal segmental hydraulic fracturing

A technology of chemical modification and hydraulic fracturing, which is used in earth-moving drilling, safety devices, discharging machinery, etc., and can solve problems such as hidden safety hazards, high production costs, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

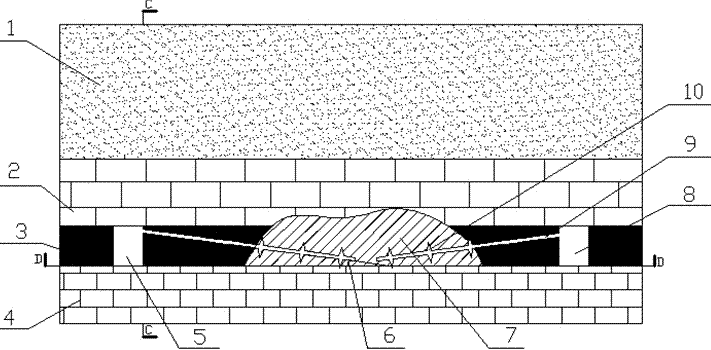

Embodiment 1

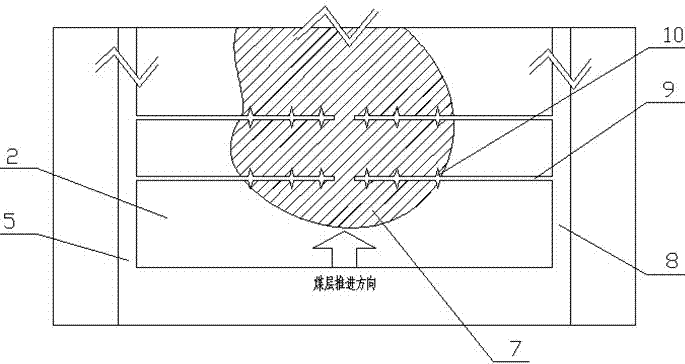

[0036] 1. Use seismic wave CT technology to find out the distribution and existence range of lamprophyre in the thick coal seam of a certain mine A. Its shape is similar to an ellipse, with a long axis of 112m and a short axis of 62m. The distance between the lamprore body and the return air roadway The nearest place is 15.2m;

[0037] 2. Along the coal wall of the return air entry and transportation entry, use the coal seam water injection drilling in the early stage to make slots in the drilling. In order to achieve better results, the distance between the water injection drilling is designed to be 5-8m in the early stage , the drill holes in the upper and lower lanes should be arranged alternately, and the angle between all the drill holes on both sides and the horizontal downward direction of the coal wall is 8 o -15 o, the downward angle not only effectively increases the pre-splitting length but also reduces waste during the later injection of chemical solutions. Each h...

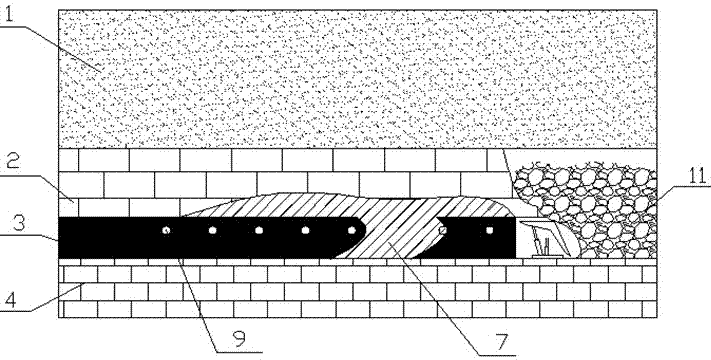

Embodiment 2

[0045] 1. Use seismic wave CT technology to find out the distribution and existence range of lamprophyre in the thick coal seam of a certain mine. Its shape is approximately circular, its average diameter is about 102m, and the nearest place to the return air tunnel is 35.6m.

[0046] 2. Along the coal wall of the return air entry and the transportation entry, use the drill holes for water injection in the coal seam in the early stage to make slots in the drill holes. In order to achieve better results, the distance between the water injection drill holes in the early design is 5- 8m, the drill holes in the upper and lower lanes should be set alternately, and the included angle between all the drill holes on both sides and the horizontal downward direction of the coal wall is 8 o -15 o , the downward angle not only effectively increases the pre-splitting length but also reduces waste during the later injection of chemical solutions. Each hole is drilled with a slotted drill ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com