Light splitting chip and preparation method thereof

A chip and spectroscopic technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of large volume, large cumulative error, and reduced yield of spectrometers, and achieve the effect of simplifying the optical path structure, reducing the volume, and improving the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

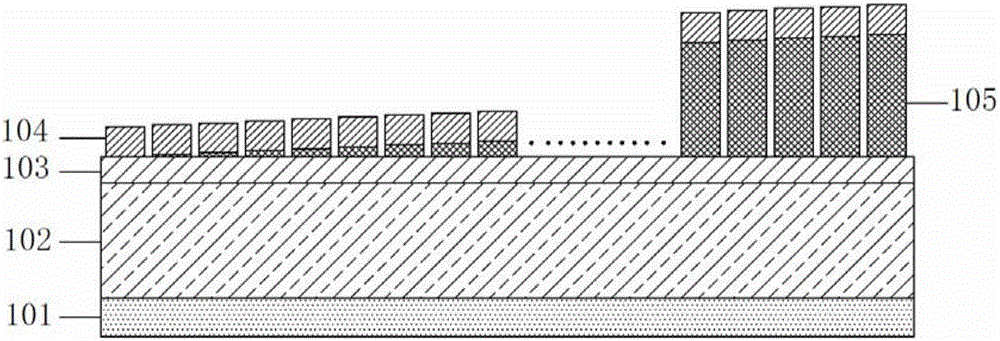

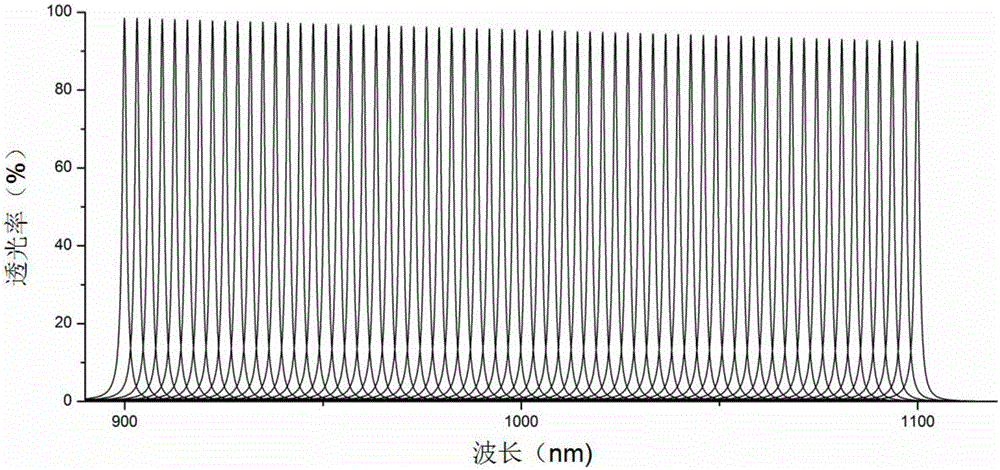

[0062] A spectroscopic chip with a working wavelength of 900-1100nm and a total of 64 channels, numbered 0-63 channels respectively, with a bandwidth of 3.1±1nm and a center wavelength accuracy of ±1nm. The central wavelength increases gradually from channel 0 to channel 63. The width of each channel is in the range of 0.01-2mm, adjacent channels are separated by black chrome, and the width of the chrome line is in the range of 0.001-1mm.

[0063] The specific manufacturing steps of the spectroscopic chip are as follows:

[0064]1. Photoetching channels and alignment marks on the sapphire substrate; wherein the photolithography includes the following steps:

[0065] a) Pretreatment: spin coating photoresist on the clean substrate 102, and bake at 80°C-100°C for more than 10 minutes;

[0066] b) Exposure: place the pretreated substrate under the mask for ultraviolet exposure;

[0067] c) Development and post-baking: the exposed substrate is developed with a developer, the ph...

Embodiment 2

[0083] A spectroscopic chip with a working wavelength of 1100-1400nm and a total of 64 channels, numbered 0-63, with a bandwidth of 4.5±1nm and a center wavelength accuracy of ±1nm. The central wavelength increases gradually from channel 0 to channel 63. The width range of each channel is 0.01-2mm, adjacent channels are separated by black chrome, and the width range of chromium line is 0.001-1mm.

[0084] The specific manufacturing steps of the spectroscopic chip:

[0085] On the sapphire substrate, the steps of photoetching channels and alignment marks, plating the first reflective film, plating the second reflective film and plating the truncation peak film system are the same as in Embodiment 1;

[0086] Wherein, the structure of the first reflection film is: λ=1200nm, H-Nb 2 o 5 , L-SiO 2 , HL H L H L H 3L.

[0087] The film structure of the second reflective film is: λ=1200nm, H-Nb 2 o 5 , L-SiO 2 , HL H L H L H 2L.

[0088] The manufacturing steps of the interme...

Embodiment 3

[0097] A spectroscopic chip with a working wavelength of 1400-1700nm and a total of 64 channels, numbered 0-63, with a bandwidth of 4.5±1nm and a center wavelength accuracy of ±1nm. The central wavelength increases gradually from channel 0 to channel 63. The width of each channel is in the range of 0.01-2mm, adjacent channels are separated by black chrome, and the width of the chrome line is in the range of 0.001-1mm.

[0098] The specific manufacturing steps of the spectroscopic chip:

[0099] On the sapphire substrate, the steps of photoetching channels and alignment marks, plating the first reflective film, plating the second reflective film and plating the truncation peak film system are the same as in Embodiment 1;

[0100] Wherein, the structure of the first reflection film is: λ=1400nm, H-Nb 2 o 5 , L-SiO 2 , HL H L H L H 3L.

[0101] The film structure of the second reflective film is: λ=1400nm, H-Nb 2 o 5 , L-SiO 2 , HL H L H L H 2L.

[0102] The steps of pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com