Method for preparing color blocking layers of liquid crystal display panels

A technology of liquid crystal panel and color resist layer, applied in the field of quantum dots, can solve the problems of reducing the brightness and color expression of the display screen, high cost, complicated methods, etc., and achieve the effect of reducing the toxicity of heavy metals and environmental pollution, and improving the brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

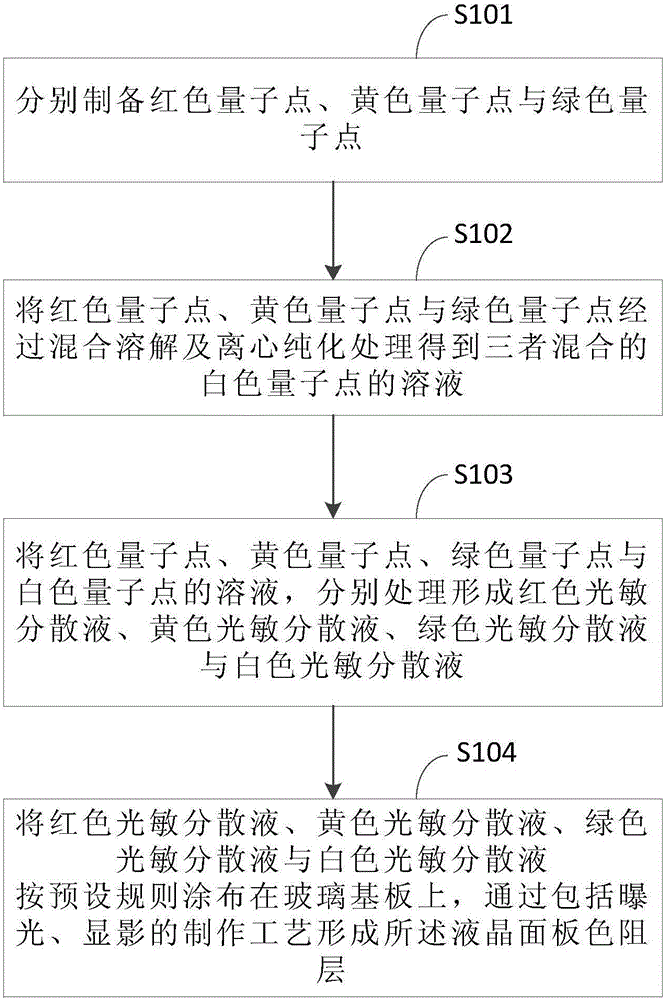

Method used

Image

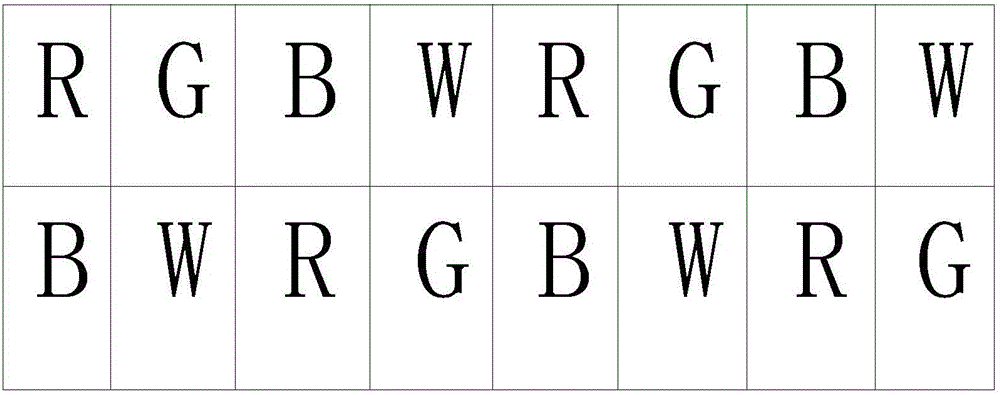

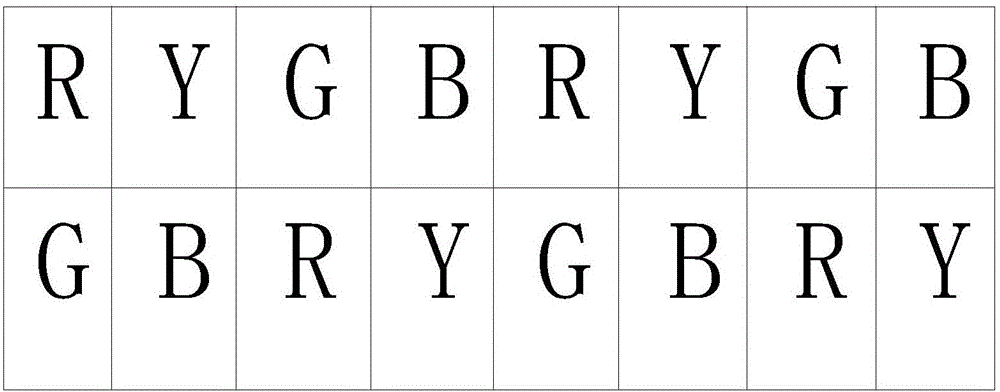

Examples

Embodiment 1

[0040] Quantum dots (quantum dots, QDs) are three-dimensional clusters with a size on the order of nanometers, so they are also called nanocrystals and nanodots. QDs materials are an interdisciplinary field involving physics, materials, nanotechnology and other disciplines. Due to the special structure of QDs, it has surface effects, quantum size effects, dielectric confinement effects, and macroscopic quantum tunneling effects, resulting in unique physicochemical properties and luminescent properties, which are completely different from the properties of the same macroscopic bulk materials. .

[0041] On the other hand, although the widely used liquid-crystal display (LCD) and light-emitting diode (LED) display devices have made breakthroughs in large size and high resolution, due to the spectral defects of their luminescent materials, these Display materials still have great challenges in picture quality and color fidelity [5-10]. Solving these challenges requires better l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com