White light source containing three-band-gap photonic crystals and preparation method for white light source

A technology of photonic crystals and white light sources, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult control of the ratio of three primary colors, light reabsorption, and affecting luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

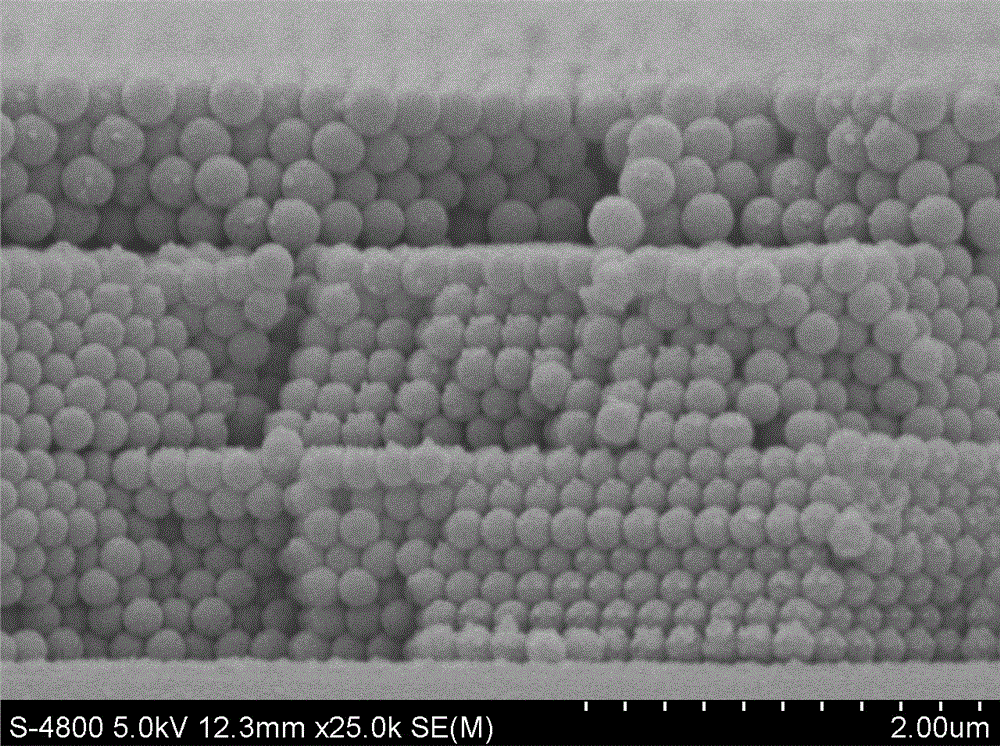

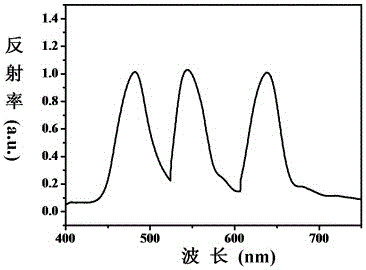

[0062] (1) Monodisperse silica particles are purchased directly, with a monodispersity of less than 3% and a particle size of 200-400 nm. Choose three monodisperse particles with particle sizes of 205 nm, 238 nm, and 293 nm. Silica particles act as seeds.

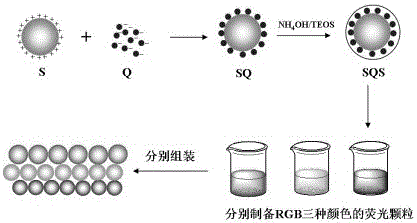

[0063] (2) Preparation of fluorescent particles

[0064] (a) Surface modification of monodisperse silica particles: Silica particles of three different particle sizes were redispersed in methanol respectively, and the concentration of silica was 5 wt%. Then add aminosilane (quality is SiO 2 10wt% of ), the solution was heated under reflux overnight, centrifuged, the obtained powder was washed 2-3 times with methanol and deionized water, and finally dispersed in ethanol respectively to obtain three kinds of silica solutions modified by amino groups with different particle sizes, The concentration of silicon dioxide is 2%. Use a small amount of hydrochloric acid solution to adjust the pH value of the amino-modified silicon ...

Embodiment 2

[0073] (1) Monodisperse silica particles are purchased directly, with a monodispersity of less than 3% and a particle size of 200-400 nm. Choose three monodisperse particles with particle sizes of 210 nm, 245 nm, and 300 nm. Silica particles act as seeds.

[0074] (2) Preparation of fluorescent particles

[0075] (a) Surface modification of monodisperse silica particles: Silica particles of three different particle sizes were redispersed in methanol respectively, and the concentration of silica was 3 wt%. Then add aminosilane (quality is SiO 2 6wt% of ), the solution was heated under reflux overnight, centrifuged, the obtained powder was washed 2-3 times with methanol and deionized water, and finally dispersed in ethanol respectively to obtain three kinds of silica solutions modified by amino groups with different particle sizes, The concentration of silicon dioxide is 2%. Use a small amount of hydrochloric acid solution to adjust the pH value of the amino-modified silicon d...

Embodiment 3

[0083](1) Preparation of monodisperse poly(styrene-methyl methacrylate-acrylic acid) (P(St-MMA-AA)) particles: P(St-MMA-AA) particles were prepared by one-step emulsion polymerization become. Weigh 0.25 g ammonium bicarbonate NH 4 HCO 3 Put it into a 100 mL three-neck flask, add 15 mL of emulsifier sodium dodecylbenzenesulfonate solution (concentration: 1 g / L), weigh 9.5 g of monomer styrene, 0.5 g of methyl methacrylate, and 0.5 g of acrylic acid Add to the flask, add deionized water, and keep the volume of the aqueous phase in the flask at 50 mL. Dissolve 0.2 g of initiator ammonium persulfate in 10 mL of deionized water to prepare a solution for use. Turn on the stirrer to stir, and control the temperature of the water bath to be 70° C., add the initiator after 20 minutes for reaction. After 1.5 hours, the temperature was raised to 80°C and kept at this temperature for 4 hours. After the reaction, the product was collected to prepare monodisperse P(St-MMA-AA) particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com