Manhole processing technology for a liquid storage tank

A hole processing and liquid storage tank technology, which is applied in the field of manhole production and processing, can solve the problems of not being able to achieve airtightness, affecting the airtightness of manholes, and damage to the base metal weld bead, so as to achieve less labor costs and lower costs Low, the effect of protection against leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A process for manhole processing of a liquid storage tank, comprising the following process steps:

[0034] 1) Take the aluminum raw material, preheat and keep it warm for a period of time, then continue to heat up to 530°C and then push it into the plate mold for extrusion molding;

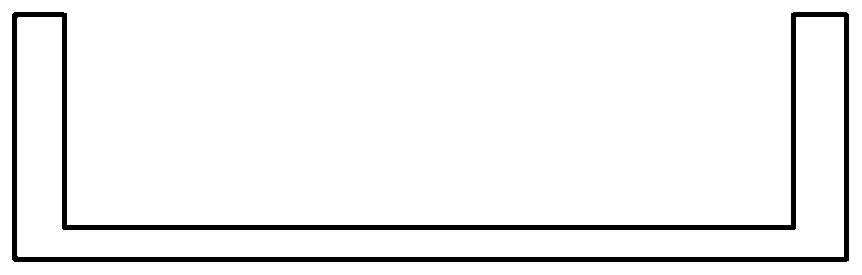

[0035] 2) The formed aluminum material discharged from the discharge port on one side of the plate mold is sent to the heat dissipation area through the transmission device, and cooled to room temperature (air cooling is adopted, and the cooling time is at least 1h) to obtain the initial product (see figure 1 , the cross-section of the formed aluminum material is "]" shape);

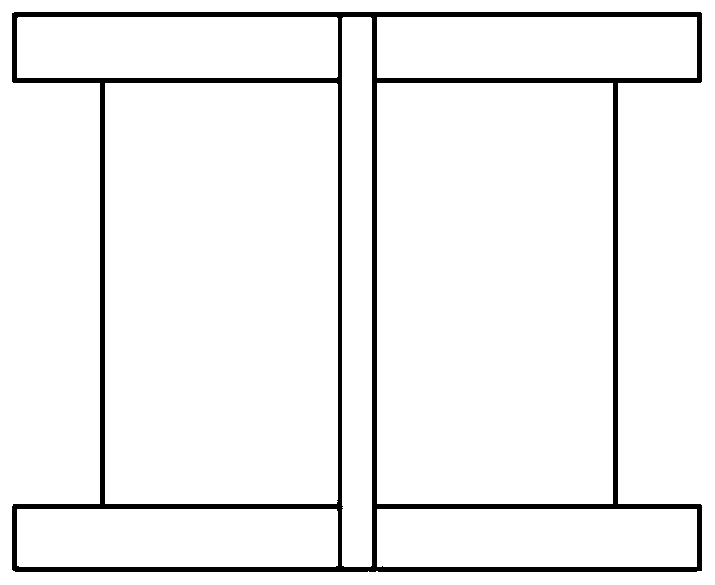

[0036] 3) The initial product is bent and rolled into a circular aluminum material of specified specifications by a rolling machine (see figure 2 ); the rolling machine adopts vertical double rollers to roll the initial product, the lower roller shaft is the driving roller connected with the motor, the upper part i...

Embodiment 2

[0041] A process for manhole processing of a liquid storage tank, comprising the following process steps:

[0042] 1) Take the aluminum raw material, preheat and keep it warm for a period of time, then continue to heat up to 550°C and then push it into the plate mold for extrusion molding;

[0043] 2) The formed aluminum material discharged from the discharge port on one side of the plate mold is sent to the heat dissipation area through the transmission device, and cooled to room temperature (air cooling is adopted, and the cooling time is at least 1h) to obtain the initial product (see figure 1 , the cross-section of the formed aluminum material is "]" shape);

[0044] 3) The initial product is bent and rolled into a circular aluminum material of specified specifications by a rolling machine (see figure 2 ); the rolling machine adopts vertical double rollers to roll the initial product, the lower roller shaft is the driving roller connected with the motor, the upper part i...

Embodiment 3

[0049] A process for manhole processing of a liquid storage tank, comprising the following process steps:

[0050] 1) Take the aluminum raw material, preheat and keep it warm for a period of time, then continue to heat up to 550°C and then push it into the plate mold for extrusion molding;

[0051] 2) The formed aluminum material discharged from the discharge port on one side of the plate mold is sent to the heat dissipation area through the transmission device, and cooled to room temperature (air cooling is adopted, and the cooling time is at least 1h) to obtain the initial product (see figure 1 , the cross-section of the formed aluminum material is "]" shape);

[0052] 3) The initial product is bent and rolled into a circular aluminum material of specified specifications by a rolling machine (see figure 2 ); the rolling machine adopts vertical double rollers to roll the initial product, the lower roller shaft is the driving roller connected with the motor, the upper part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com