Baked dried bamboo shoot and making process thereof

A production process and a technology for roasting bamboo shoots, applied in the directions of food drying, food processing, food science, etc., can solve the problems of cumbersome process, lack of fragrance of bamboo shoots, poor taste of dried bamboo shoots, etc., to achieve simple process, retain fragrance and sweetness, Better taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A production process of raw roasted dried bamboo shoots, comprising the following steps:

[0035] Ⅰ. Pretreatment: shell and wash the fresh bamboo shoots.

[0036] Ⅱ. Shaping: remove the inedible parts of the fresh bamboo shoots washed in step Ⅰ, and cut them into bamboo strips. The length of the bamboo shoots is about 30cm, and the width of the bamboo shoots is about 12cm. Wash and drain after completion.

[0037] Ⅲ. Baking: Send the bamboo shoots in step Ⅱ directly to the conventional bamboo shoot device. Baking is divided into three stages: Stage 1: Baking temperature is 80°C, baking time is 5 hours, and exhaust air and moisture are carried out ; Stage 2 consists of a heating section and a maintenance section. The baking temperature of the heating section is 115°C, and the baking time is 1h. The baking time is 19 hours, and exhaust air and moisture are carried out; in the third stage, the baking temperature is 90°C, and the baking time is 5 hours, and air exhaust an...

Embodiment 2

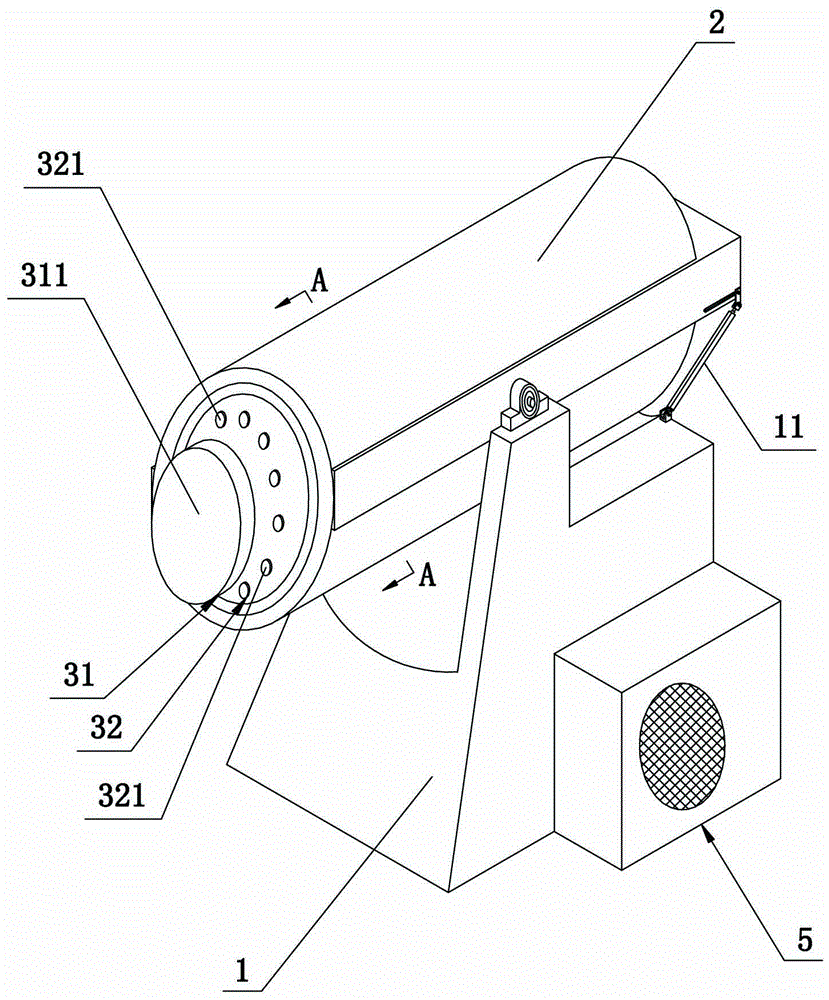

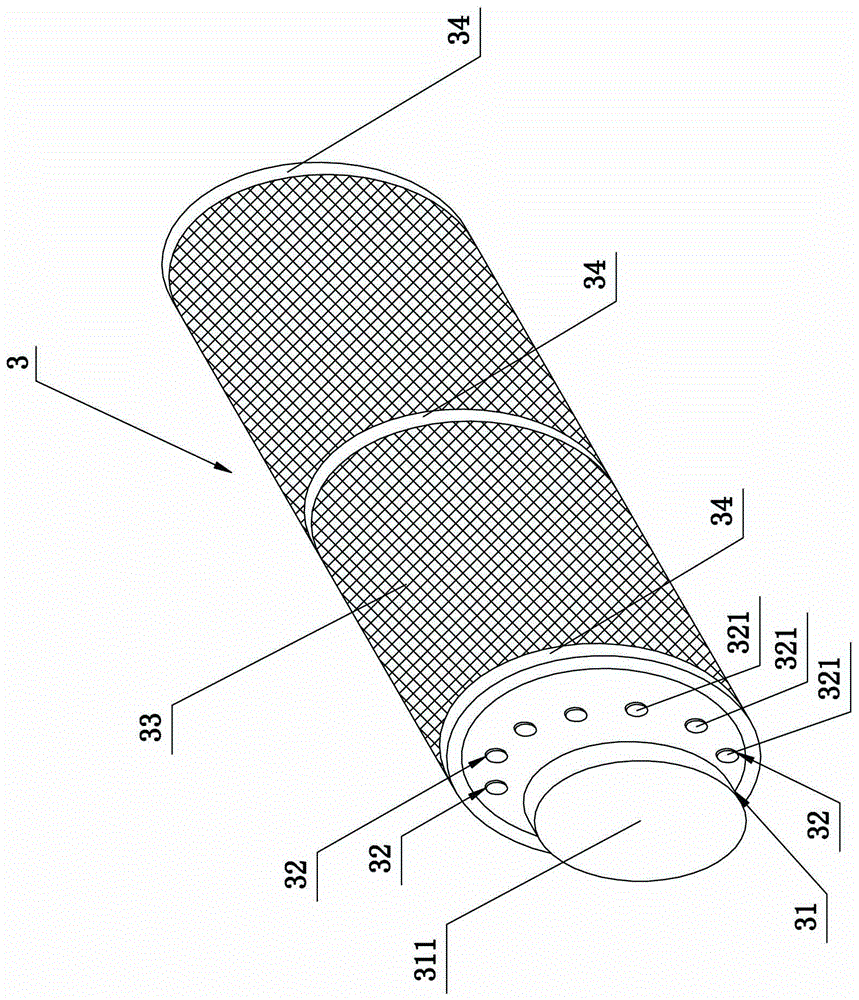

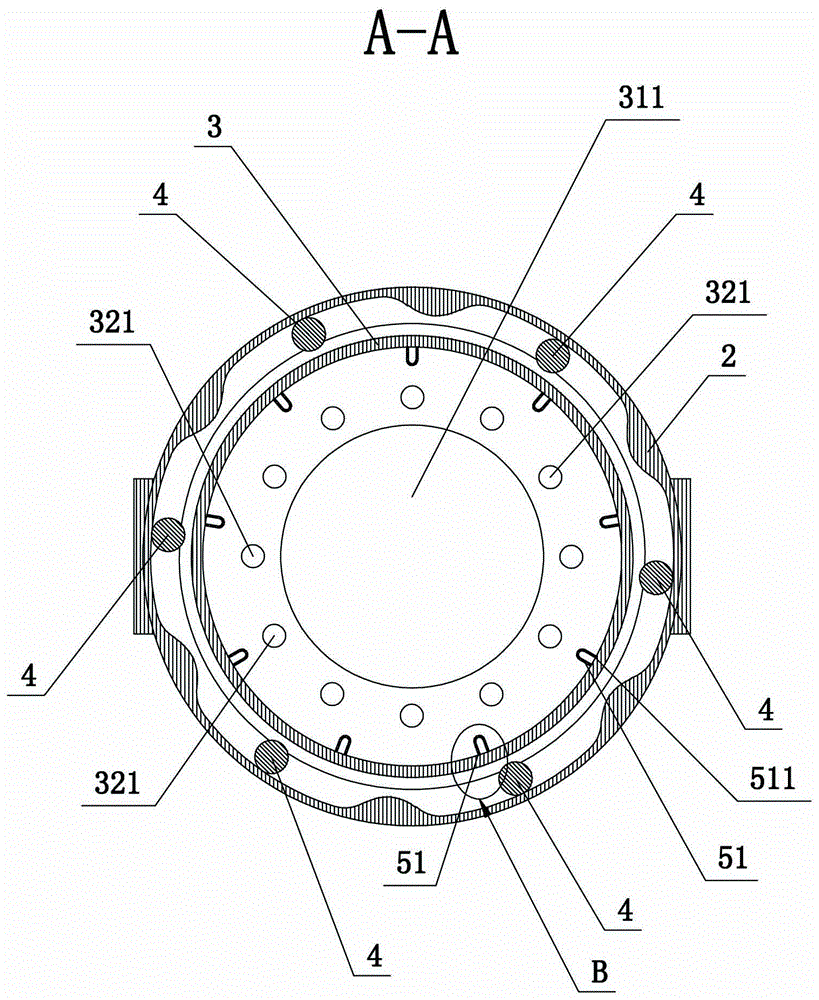

[0040] refer to figure 1 , figure 2 , image 3 , Figure 4, a bamboo shoot machine used in the production process of raw and dried bamboo shoots, including a base 1, a baking cylinder 2, a material cylinder 3, an infrared baking device and an air energy baking device 5, and the middle part of the baking cylinder 2 can be fixed Rotately assembled on the base 1. A cylinder 11 is hinged on the base 1 , and the other end of the cylinder 11 is hinged to the tail end of the baking cylinder 2 . The baking cylinder 2 is sheathed outside the material cylinder 3 , and the material cylinder 3 is rotatably assembled in the baking cylinder 2 . The tail end of the baking cylinder 2 is attached with a drive motor (not shown) that drives the rotation of the material cylinder 3 . The infrared baking device includes 6 infrared generating tubes 4 , and the infrared generating tubes 4 are evenly arranged on the inner edge of the baking tube 2 extending along the length direction of the baki...

Embodiment 3

[0048] A production process of raw roasted dried bamboo shoots, comprising the following steps:

[0049] Ⅰ. Pretreatment: shell and wash the fresh bamboo shoots.

[0050] Ⅱ. Shaping: Remove the inedible parts of the fresh bamboo shoots washed in step Ⅰ, cut into shredded bamboo shoots, wash and drain after completion.

[0051] Ⅲ. Roasting: Send the shredded bamboo shoots in step Ⅱ directly to the conventional bamboo shoot device, and the baking is divided into three stages: stage 1: the baking temperature is 50°C, the baking time is 1 hour, and the air and humidity are exhausted ; Stage 2 consists of a heating section and a maintenance section. The baking temperature of the heating section is 85°C, and the baking time is 1h. The baking time is 9 hours, and exhaust air and moisture are carried out; in the third stage, the baking temperature is 70°C, and the baking time is 5 hours, and air exhaust and moisture exhaust are performed.

[0052] Ⅳ. Packaging: Take out the shredded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com