Nitrogen-doped graphene quantum dot and graphite-phase carbon nitride composite photocatalyst and preparation method thereof

A technology of graphene quantum dots and graphitic carbon nitride is applied in the field of photocatalysis to achieve the effects of high catalytic activity, good stability, and improved activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

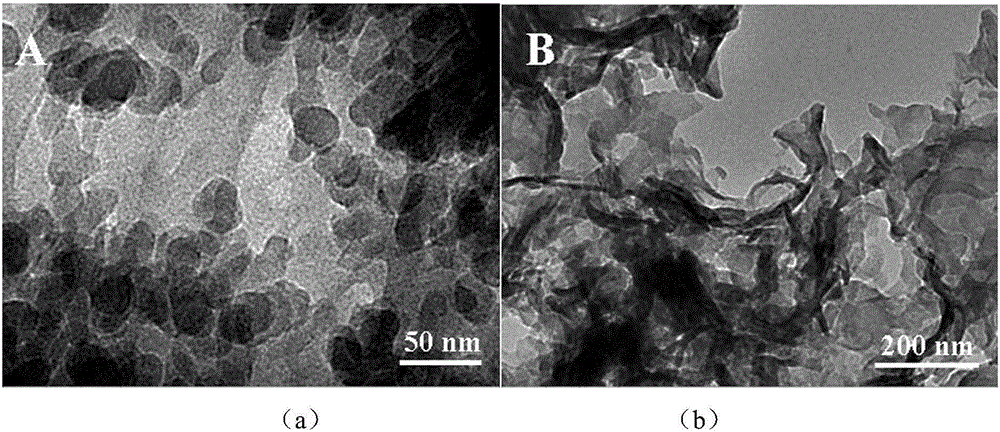

[0029] Weigh 0.21g (1mmol) of citric acid and 0.18g (3mmol) of urea and dissolve them in 30mL of distilled water, stir until a clear solution is formed, then transfer the solution to a 50mL polytetrafluoroethylene-lined stainless steel autoclave. Heating at 160°C for 4 hours at a constant temperature. Ethanol was added to the obtained product and centrifuged at 8000rpm for 10 minutes to obtain a solid, which was washed several times with ethanol and then dried at 60°C to obtain the final product N-GQDs. Disperse N-GQDs in water again, and its morphology is as figure 1 as shown in (a);

[0030] Dissolve 10 g of urea in a solution containing 17 mL of N-GQDs (0.2 mg / mL). After the sample is evaporated to dryness, it is calcined in a covered alumina crucible at 20 °C / min to 550 °C for 3 h, and then cooled to room temperature to obtain N-GQDs / g-C 3 N 4 complex, whose form is as figure 1 as shown in (b);

[0031] 1.32mL of H 2 PtCl 6Aqueous solution (7.723mmol / L) and 100mg o...

Embodiment 2

[0034] Weigh 0.63g (3mmol) of citric acid and 0.18g (3mmol) of urea and dissolve them in 30mL of distilled water, stir until a clear solution is formed, and then transfer the solution to a 50mL polytetrafluoroethylene-lined stainless steel autoclave. Heating at 160°C for 4 hours at a constant temperature. Ethanol was added to the obtained product and centrifuged at 8000rpm for 10 minutes to obtain a solid, which was washed several times with ethanol and then dried at 60°C to obtain the final product N-GQDs. The N-GQDs were dispersed into water again.

[0035] Put 10 g of urea into a covered alumina crucible and calcinate at 20 °C / min to 550 °C and maintain for 3 h. After cooling to room temperature, the solid product obtained can be ground to obtain pure g-C 3 N 4 sample.

[0036] Preparation of composite N-GQDs / g-C by traditional impregnation method 3 N 4 (D). 0.1g pure g-C 3 N 4 Mix with 5mL N-GQDs (0.2mg / mL) solution, stir magnetically at room temperature for 12h, c...

Embodiment 3

[0040] Weigh 0.315g (1.5mmol) of citric acid and 0.18g (3mmol) of urea and dissolve them in 30mL of distilled water, stir until a clear solution is formed, and then transfer the solution to a 50mL polytetrafluoroethylene-lined stainless steel autoclave. Heating at 160°C for 4 hours at a constant temperature. Ethanol was added to the obtained product and centrifuged at 8000rpm for 10 minutes to obtain a solid, which was washed several times with ethanol and then dried at 60°C to obtain the final product N-GQDs. The N-GQDs were dispersed into water again.

[0041] Dissolve 10 g of urea in a solution containing 25 mL of N-GQDs (0.2 mg / mL). After the sample is evaporated to dryness, it is calcined in a covered alumina crucible at 20 °C / min to 550 °C for 3 h, and then cooled to room temperature to obtain N-GQDs / g-C 3 N 4 Complex.

[0042] 1.98 mL of H 2 PtCl 6 Aqueous solution (7.723mmol / L) and 100mg of N-GQDs / g-C 3 N 4 The complex was added to 50mL of 20vol% ethanol aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com