Preparation method of heterojunction visible-light-induced photocatalyst and application thereof

A photocatalyst and heterojunction technology, applied in the field of environmental remediation and pollution control, can solve the problems of recyclability and catalytic efficiency that cannot be achieved, large particle size, and low catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

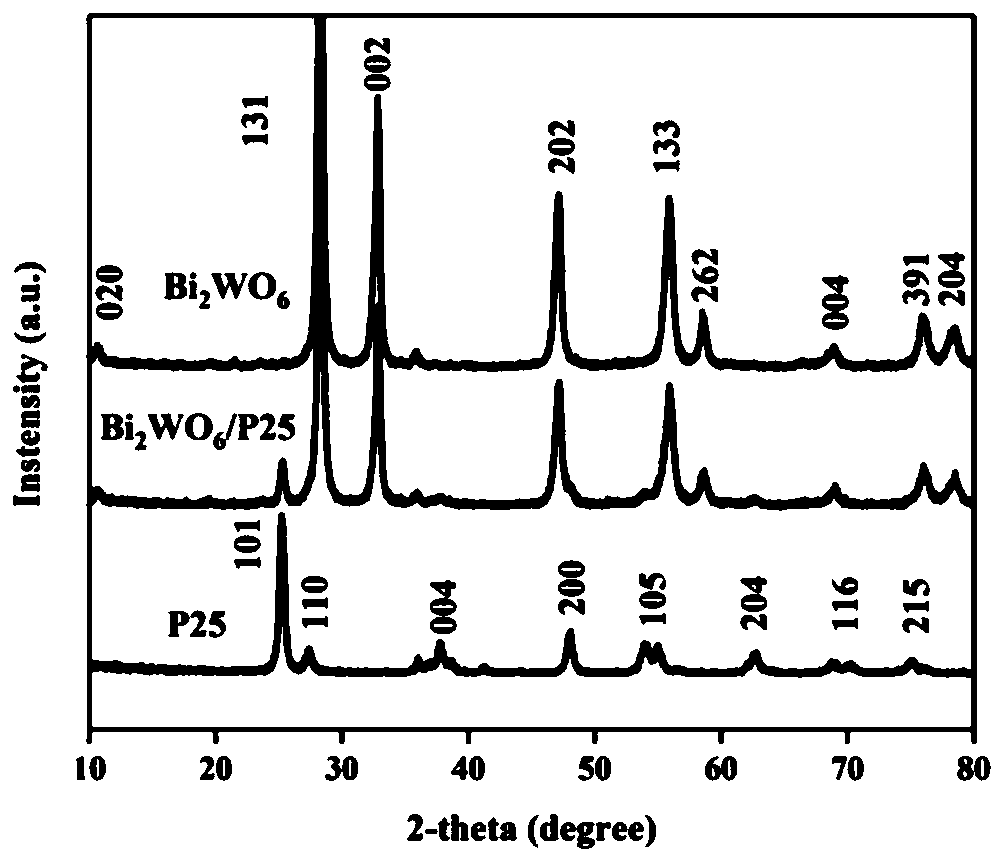

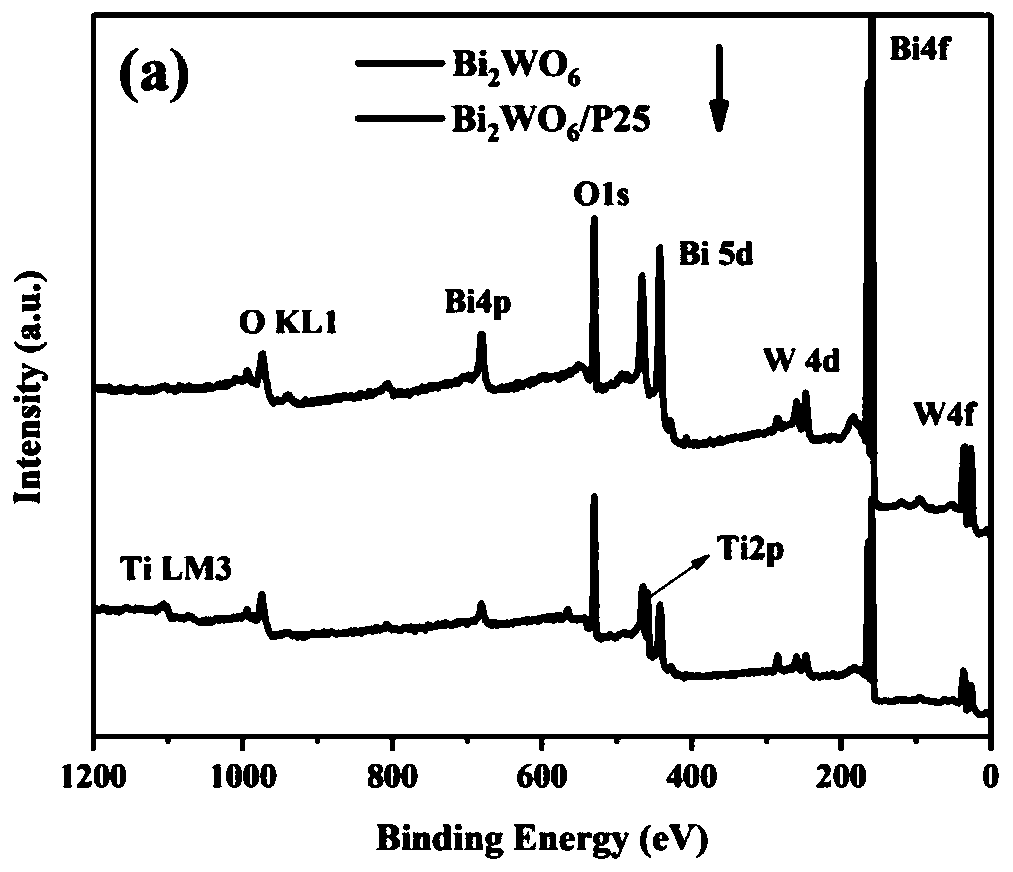

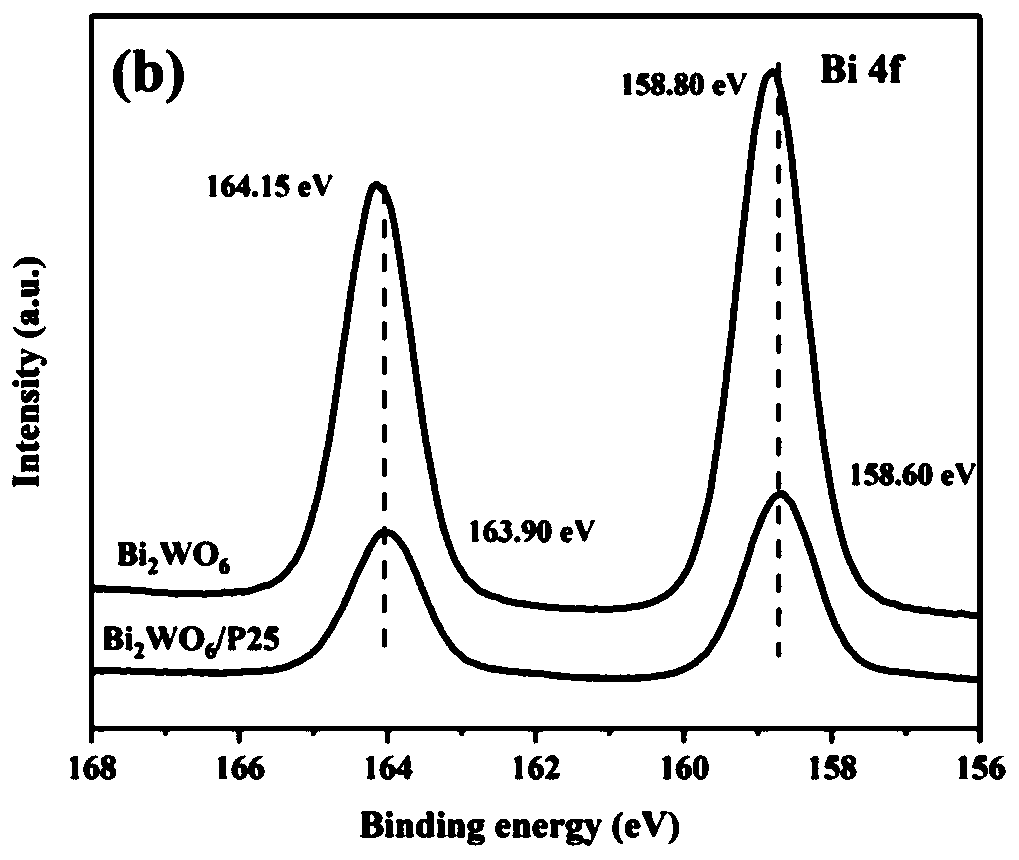

[0032] This example provides Bi 2 WO 6 The preparation method of P25 heterojunction visible light catalyst comprises the following steps:

[0033] (1) Add 80 g of sucrose into 500 mL of deionized water, stir magnetically for 60 min to dissolve the sucrose, transfer it to a polytetrafluoroethylene-lined reactor, put it into a muffle furnace and burn it at 200 °C for 2 h. After cooling, wash with deionized water and absolute ethanol three times respectively, and dry the obtained precipitate in an oven at 80°C to obtain a carbon microsphere template.

[0034] (2) 2mmol Bi(NO 3 ) 3 ·5H 2 O and 1 mmol Na 2 WO 4 2H 2 O was dissolved in 80 mL of ethylene glycol to form a mixed solution, stirred magnetically for 10 min, continued to add 0.5 g of carbon microspheres and stirred for 30 min, then added 6 mmol P25, stirred in a water bath at 60 °C for 6 h, and centrifuged with deionized water and absolute ethanol. Impurities were removed by washing 3 times, and the obtained substa...

Embodiment 2

[0049] (1) Add 80 g of sucrose to 500 mL of deionized water, stir magnetically for 40 min to dissolve the sucrose, transfer it to a polytetrafluoroethylene-lined reactor, put it into a muffle furnace and burn at 190°C for 2 h. After cooling, wash with deionized water and absolute ethanol three times respectively, and dry the obtained precipitate in an oven at 60°C to obtain a carbon microsphere template.

[0050] (2) 2mmol Bi(NO 3 ) 3 ·5H 2 O and 1 mmol Na 2 WO 4 2H 2 O was dissolved in 80 mL of ethylene glycol to form a mixed solution, stirred magnetically for 8 min, continued to add 0.3 g of carbon microspheres and stirred for 30 min, then added 3 mmol P25, stirred in a water bath at 60 °C for 6 h, and centrifuged with deionized water and absolute ethanol. Impurities were removed by washing 3 times, and the obtained substance was dried at 60° C. for 12 hours.

[0051] (3) Transfer the dried powder to a crucible, put it into a muffle furnace and burn it at 400°C for 5 h...

Embodiment 3

[0053](1) Add 100 g of sucrose to 500 mL of deionized water, stir magnetically for 50 min to dissolve the sucrose, transfer it to a polytetrafluoroethylene-lined reaction kettle, put it into a muffle furnace and burn at 200°C for 2.5 h. After cooling, wash with deionized water and absolute ethanol three times respectively, and dry the obtained precipitate in an oven at 70°C to obtain a carbon microsphere template.

[0054] (2) 3mmol Bi(NO 3 ) 3 ·5H 2 O and 1.5 mmol Na 2 WO 4 2H 2 O was dissolved in 80mL of ethylene glycol to form a mixed solution, stirred magnetically for 9min, continued to add 0.4g of carbon microspheres and stirred for 45min, then added 6mmol P25, stirred in a water bath at 65°C for 7h, and centrifuged with deionized water and absolute ethanol respectively. Impurities were removed by washing 3 times, and the obtained substance was dried at 70° C. for 12 hours.

[0055] (3) Transfer the dried powder to a crucible, put it into a muffle furnace and burn i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com