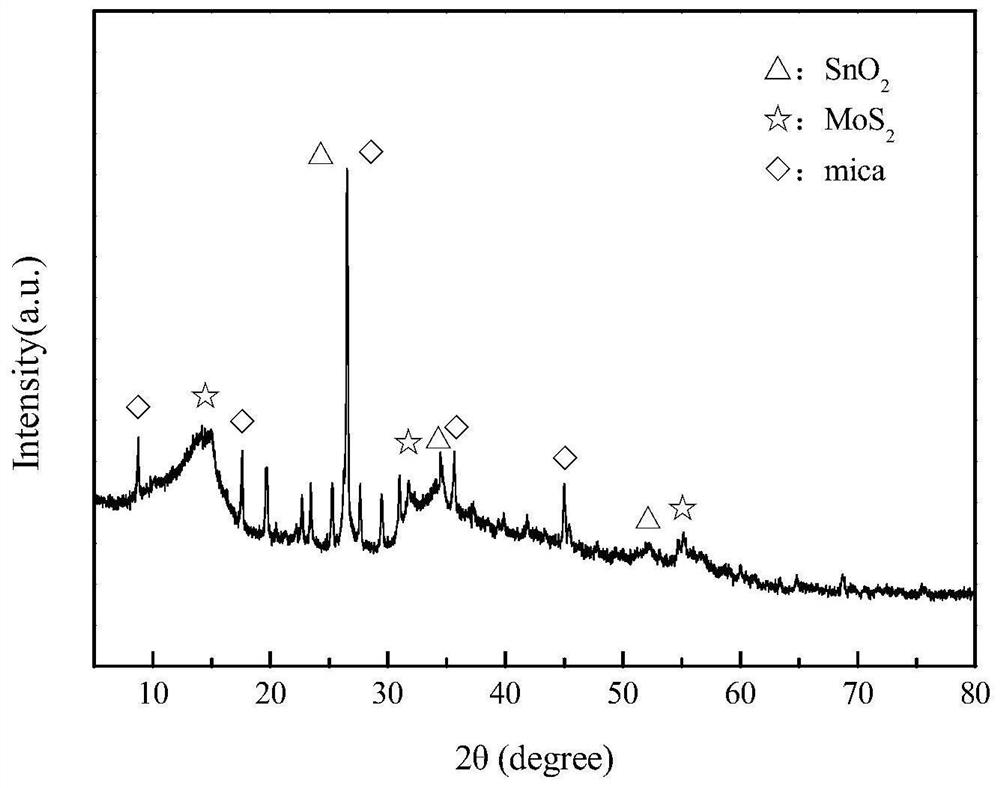

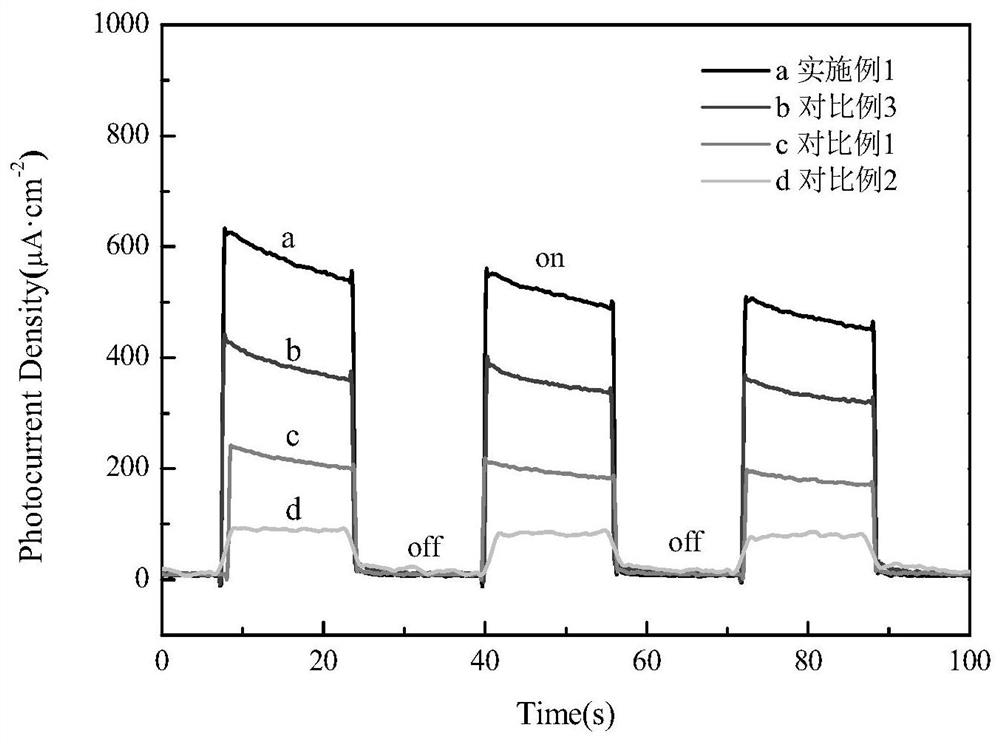

A kind of molybdenum disulfide/tin dioxide/mica composite material and preparation method thereof for photogenerated cathodic protection

A photogenerated cathodic protection and tin dioxide technology, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of low utilization efficiency of visible light, large band gap, easy recombination with holes, etc. , to achieve the effect of improving the visible light response range, enhancing the conductivity rate, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

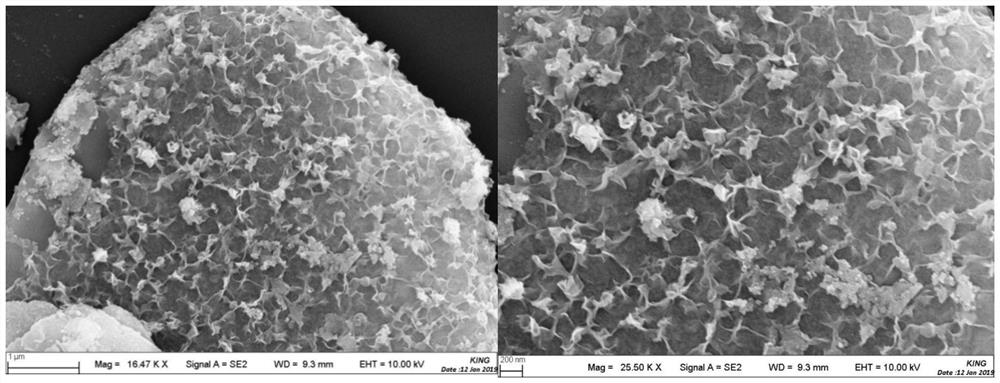

Embodiment 1

[0020] 1. Disperse 200g of mica in 1L of deionized water, heat to 75°C while stirring, adjust the pH to 2.5, add tin tetrachloride pentahydrate solution (1.55L, 300g / L) dropwise to the dispersion, and add hydrogen at the same time Sodium oxide solution (4mol / L) kept the pH of the mixed solution at 2.5, and continued to stir at 75°C for 2h. After cooling to room temperature, suction filtered and washed to neutral. The washed sample was dried at 70°C and dried at 600°C. calcined at lower temperature to obtain tin dioxide / mica composite material;

[0021] 2. Add 270mg of sodium molybdate, 540mg of thioacetamide and 120mg of the tin dioxide / mica composite material prepared in Step 1 into 60mL of deionized water, stir evenly and put it into a hydrothermal kettle, then move the hydrothermal kettle into the oven , under the condition of 220°C for hydrothermal reaction for 24h, after cooling to room temperature, suction filtration, the filter cake was washed and dried at 70°C to obtai...

Embodiment 2

[0023] 1. Disperse 150g of mica in 1L of deionized water, heat to 70°C while stirring, adjust the pH to 2, add tin tetrachloride pentahydrate solution (0.875L, 200g / L) dropwise to the dispersion, and add hydrogen at the same time Sodium oxide solution (3mol / L) kept the pH of the mixed solution at 2, and continued to stir at 70°C for 1h. After cooling to room temperature, suction filtered and washed to neutrality. The washed sample was dried at 60°C and dried at 500°C. calcined at lower temperature to obtain tin dioxide / mica composite material;

[0024] 2. Add 180mg of sodium molybdate, 360mg of thioacetamide and 120mg of the tin dioxide / mica composite material prepared in step 1 into 60mL of deionized water, stir evenly and put it into a hydrothermal kettle, then move the hydrothermal kettle into the oven , hydrothermal reaction at 200°C for 12h, after cooling to room temperature, suction filtration, washing the filter cake and drying at 60°C to obtain molybdenum disulfide / tin...

Embodiment 3

[0026] 1. Disperse 250g of mica in 1L of deionized water, heat to 80°C while stirring, adjust the pH to 3, add tin tetrachloride pentahydrate solution (2.9L, 400g / L) dropwise to the dispersion, and add hydrogen at the same time Sodium oxide solution (5mol / L) kept the pH of the mixed solution at 3, continued to stir at 80°C for 3h, after cooling to room temperature, suction filtered and washed to neutral, the washed sample was dried at 80°C, and dried at 700°C calcined at lower temperature to obtain tin dioxide / mica composite material;

[0027] 2. Add 360mg of sodium molybdate, 720mg of thioacetamide and 120mg of the tin dioxide / mica composite material prepared in step 1 into 60mL of deionized water, stir evenly and put it into a hydrothermal kettle, then move the hydrothermal kettle into the oven , hydrothermal reaction at 240°C for 36h, after cooling to room temperature, suction filtration, washing the filter cake and drying at 80°C to obtain molybdenum disulfide / tin dioxide / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com