Polyaniline-coated phenolic resin catalyst with core-shell structure and preparation method of polyaniline-coated phenolic resin catalyst

A phenolic resin, core-shell structure technology, applied in the field of photocatalysis, can solve the problem that biological toxicity cannot be ignored, and achieve the effects of efficient regeneration of NADH, accelerated transfer and utilization, and accelerated separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

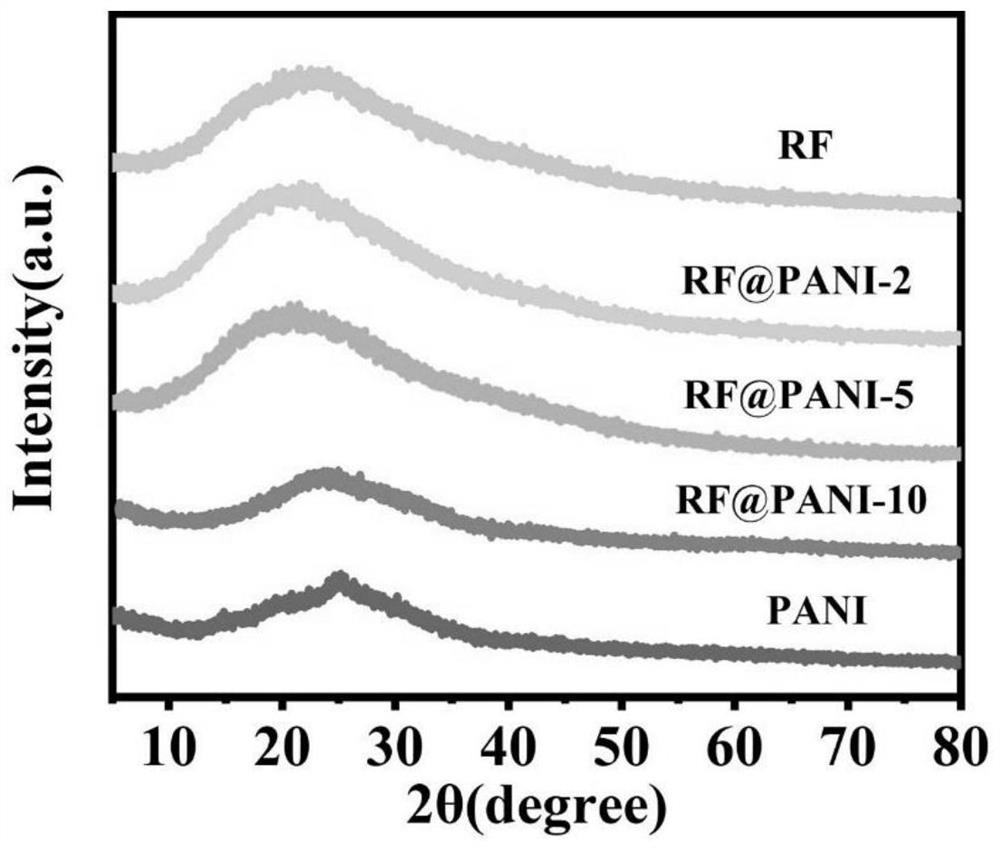

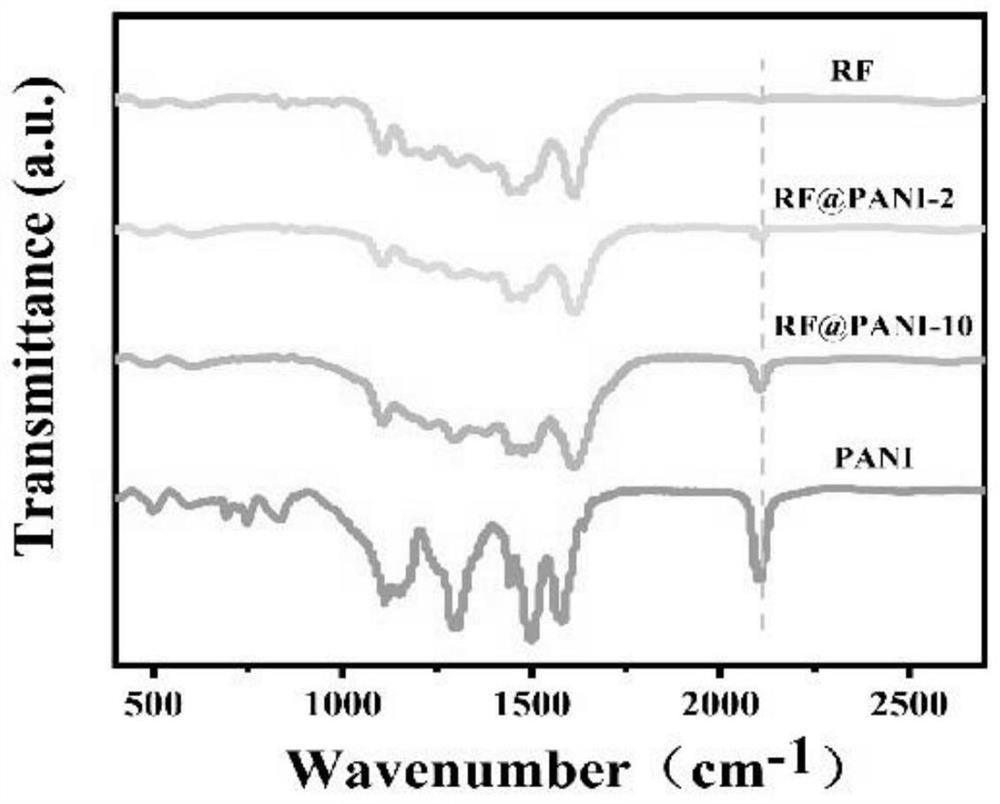

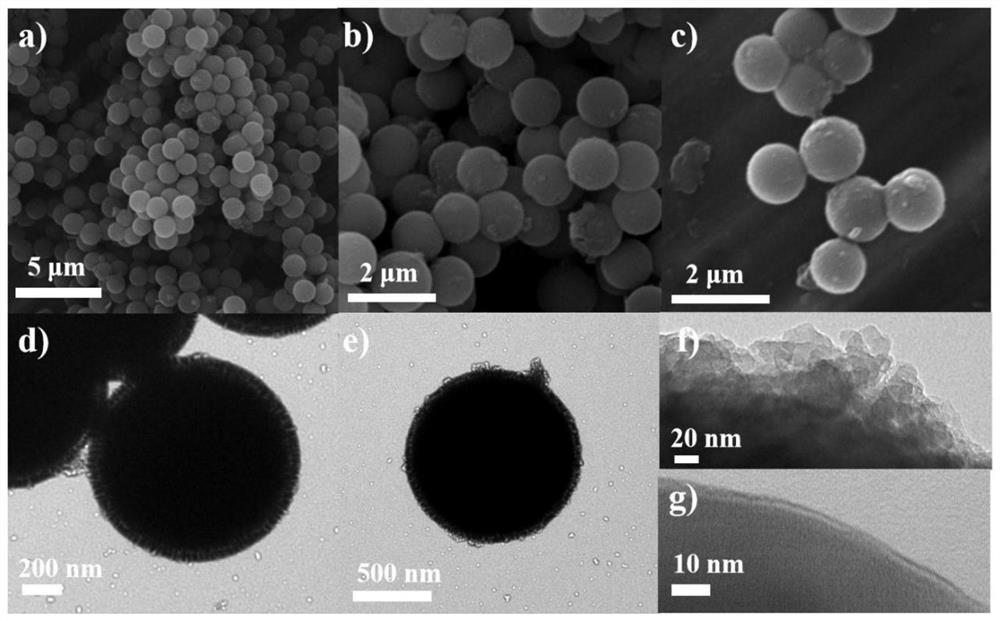

[0030] To prepare RF@PANI-1, the content of PANI added is 1%:

[0031] Add 1.5mmol of resorcinol to a mixed solution containing 40mL of water and 10mL of ethanol and stir for 20min, then add 1.5mmol of formaldehyde solution with a concentration of 36wt% dropwise, stir at room temperature for 60min, and finally add 18wt% of ammonia water 0.2 mL, and stirred at 40°C for 24 hours, centrifuged and washed to obtain phenolic resin balls; 250 mg of phenolic resin balls were added to a mixed solution containing 20 mL of water and 20 mL of ethanol, kneaded and ultrasonically stirred for 30 min, then 2.5 mg of polyaniline was added and stirred for 10 min , and then use a 300w xenon lamp to continue to irradiate for 2 hours under continuous stirring in the full range, and finally centrifuge and wash to obtain RF@PANI-1.

Embodiment 2

[0033] To prepare RF@PANI-2, the content of PANI added is 2%:

[0034] Add 1.5mmol of resorcinol to a mixed solution containing 40mL of water and 10mL of ethanol and stir for 20min, then add 1.5mmol of formaldehyde solution with a concentration of 36wt% dropwise, stir at room temperature for 60min, and finally add 18wt% of ammonia water 0.2 mL, and stirred at 40°C for 24 hours, centrifuged and washed to obtain phenolic resin balls; 250 mg of phenolic resin balls were added to a mixed solution containing 20 mL of water and 20 mL of ethanol and stirred ultrasonically for 30 minutes, then 5 mg of polyaniline was added and stirred for 10 minutes. Then use a 300w xenon lamp to continue to irradiate for 2 hours under continuous stirring in the full band, and finally centrifuge and wash to obtain RF@PANI-2.

Embodiment 3

[0036] To prepare RF@PANI-3, the content of PANI added is 3%:

[0037] Add 1.5mmol of resorcinol to a mixed solution containing 40mL of water and 10mL of ethanol and stir for 20min, then add 1.5mmol of formaldehyde solution with a concentration of 36wt% dropwise, stir at room temperature for 60min, and finally add 18wt% of ammonia water 0.2 mL, and stirred at 40°C for 24 hours, centrifuged and washed to obtain phenolic resin balls; 250 mg of phenolic resin balls were added to a mixed solution containing 20 mL of water and 20 mL of ethanol, kneaded and ultrasonically stirred for 30 min, then 7.5 mg of polyaniline was added and stirred for 10 min , and then use a 300w xenon lamp to continue to irradiate for 2 hours under continuous stirring in the full band, and finally centrifuge and wash to obtain RF@PANI-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com