Ridge prism cemented component production technology and fixture thereof

A roof prism and production process technology, applied in prisms, grinding workpiece supports, etc., can solve the problems of product accuracy not meeting the drawing requirements, low work efficiency, long grinding time, etc., to ensure consistent processing and high production efficiency , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

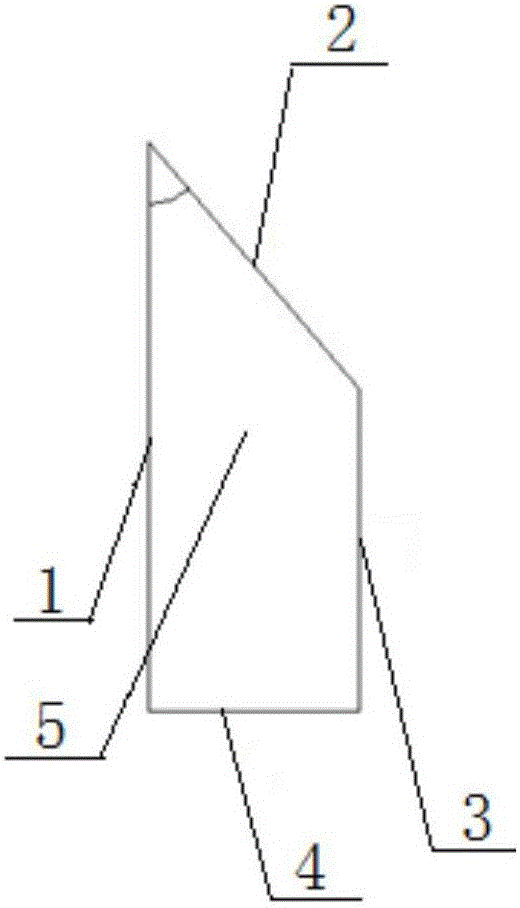

[0048] A kind of production process of roof prism glued parts of the present embodiment, the operation steps are:

[0049] Step 1, processing of the large surface 1 and the third surface 3: grinding and polishing the large surface 1 and the third surface 3 of the roof prism wool;

[0050] Step 2, processing of the fourth side 4: grinding and polishing the fourth side 4 of the roof prism wool;

[0051] Step 3, processing of the second surface 2; grinding and polishing the second surface 2 of the roof prism wool;

[0052] Step 4, coating processing: use a vacuum coating machine to coat the large surface 1 with an anti-reflective coating, and the second surface 2 with a reflective coating, and add black paint for protection to obtain a single piece of semi-finished product;

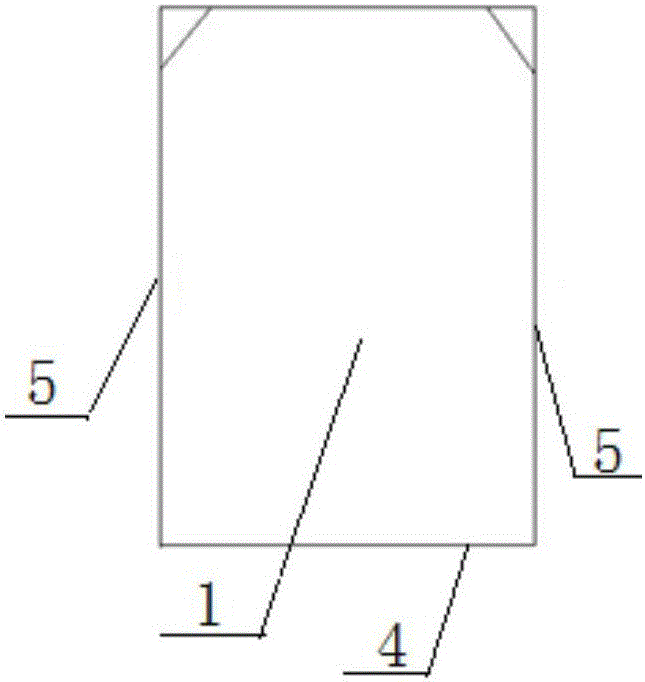

[0053] Step five, gluing: After cleaning the third surface 3, glue the third surface 3 of the two semi-finished products together with optical special glue to form a Figure 4 glued parts shown;

[0054] St...

Embodiment 2

[0059] A kind of production process of roof prism glued parts of the present embodiment, the specific steps are basically the same as embodiment 1, the improvement is: after step 1 is processed, the parallelism of the two sides of the large surface 1 and the third surface 3 is controlled within 15 ", and the size The error is within ±0.01mm; after step 2 processing, the 90° angle between the large surface 1 and the fourth surface 4 is within ±10"; after step 3 processing, the edge difference is within 15", the large surface 1 and the second surface The error of the included angle between the two is within 15", and the error of the total length is within 0.02mm; the components and proportions of the black paint described in step 3 are the main agent: hardener: thinner = 8:1:7; glue in step 5 The adhesive layer of the piece has no bubbles and is not clean. Use a 15-second goniometer to control the parallelism between the two sides 1 within 10", and check the two fourth sides 4 wi...

Embodiment 3

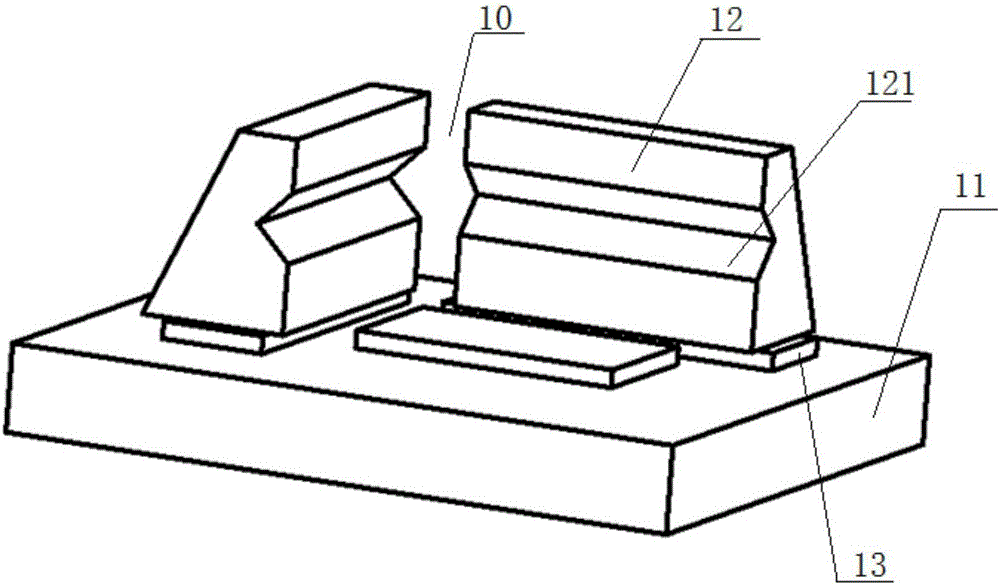

[0061] A kind of roof prism glued piece production process of this embodiment, the specific steps are the same as embodiment 2, and the improvement is: in the step 5, it is carried out in the glued piece tooling 10, which can ensure the consistency and accuracy of product processing; In step 6, a glue groove is provided in the middle of the 45° body 16 large surface of the tooling to avoid overflow of glue and affect the working and processing surface of the body and workpiece. like image 3 As shown, step five glued tooling 10 includes a base 11 and a limit block 12. The specific use steps are: glue the large surface 1 of a single semi-finished product on the base 11, and stick the side 5 to the limit block 12. The surface of the third surface 3 is coated with optical special glue, and the third surface 3 of another single semi-finished product is facing downward, and the side 5 is facing the limit block 12. Push gently on the surface of the third surface 3 of the previous si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com