Light-ageing-resistant outdoor recombined bamboo manufacturing method and product

A technology of light aging resistance and manufacturing method, which is applied in the direction of manufacturing tools, building structures, and the joining of wooden veneers, which can solve the problems of difficulty in uniform dispersion of inorganic nanoparticles and reduce the absorption capacity of coatings, etc., to increase the scope of application and service life, superior economic benefits, and advanced lamination technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: a kind of anti-aging outdoor recombinant bamboo manufacturing method comprises the following steps:

[0031] 1 Bamboo substrate preparation process:

[0032] 1) Unit preparation: directional separation of fibers, sawing the moso bamboo into 2.6m long bamboo tubes, dissecting it into bamboo slices and removing green (if you need to keep the green color of bamboo, the step of removing green is not required), and disperse to make bamboo bundles .

[0033] 2) Bamboo bundle woven curtain: use manual or mechanical weaving into large bamboo bundle pieces. The feeding speed of mechanical knitting is 5m / min, and the needle gap is 25mm.

[0034] 3) Bamboo curtain / bundle heat treatment: place bamboo curtain / bamboo bundle in water vapor or other inert gas or oil bath for heat treatment, the treatment temperature is 160-220°C, and the treatment time is 0.5-6h.

[0035] 4) Glue dipping: place the bamboo bundle curtain / bamboo bundle dried to a moisture content of 6%-8% ...

Embodiment 2

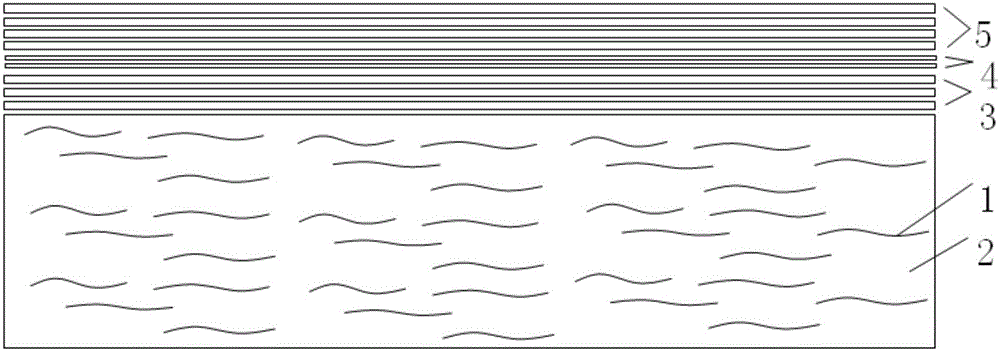

[0054] Embodiment 2: adopt the product of above-mentioned light aging resistance outdoor recombinant bamboo manufacture method, as attached figure 1 As shown, it includes an outdoor reorganized bamboo base material 2 spliced and pasted by bamboo bundles 1. There are 2-3 layers of UV curable primer layer 3 above the outdoor restructured bamboo base material 2, and 1-3 layers of UV curable primer layer 3 are provided above the UV curable primer layer 3. 3 layers of sanding primer layer 4, 2-4 layers of UV curing topcoat layer 5 are arranged above the sanding primer layer 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com