Nanometer ceramic paint for pre-painting of metal printing plates with rollers and preparation method thereof

A nano-ceramic and nano-ceramic resin technology, which is applied in the field of pre-roller coating nano-ceramic coatings for metal printing plates and its preparation, can solve the problems of affecting appearance and service life, increasing the cost of use, scratching the surrounding parts, etc., and achieve excellent non-combustibility Resistance and insulation, good compatibility, not easy to scratch or form the effect of abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

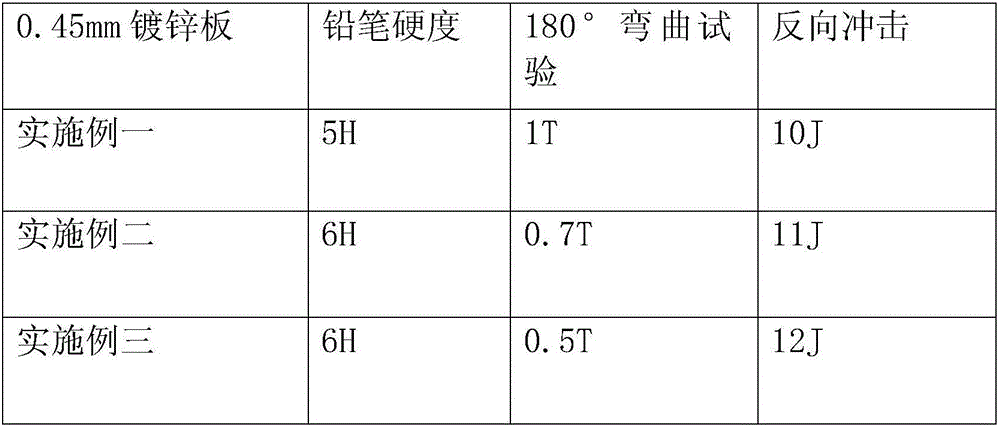

Embodiment 1

[0015] A kind of preparation method of pre-roller coating nano-ceramic coating for metal printing plate, this preparation method comprises following preparation steps:

[0016] (1) Prepare the following components in parts by weight: 80 parts of nano-ceramic resin, 15 parts of curing agent, 4 parts of fumed silica, 2.5 parts of fluorocarbon surfactant, 35 parts of isophorone, and 4 parts of additives ;

[0017] (2) Disperse the nano-ceramic resin and the solvent in the reactor using a disperser, and stir and disperse for 15-20min at a rotating speed of 800-1000 rpm;

[0018] (3) Add fluorocarbon surfactants, matting agents and additives to the product of step (2) and add them to the reactor in order to mix and stir for 30-40min, then add curing agent, reduce the speed by 20% and stir for 20-30min, and use a 200-mesh sieve Net filtration, get pre-roller coated nano-ceramic coating.

[0019] Wherein, in the step (1), the nano-ceramic resin is composed of nano-scale powder 20, ...

Embodiment 2

[0022] A kind of preparation method of pre-roller coating nano-ceramic coating for metal printing plate, this preparation method comprises following preparation steps:

[0023] (1) Prepare the following components in parts by weight: 75 parts of nano-ceramic resin, 13 parts of curing agent, 3 parts of fumed silica, 2.0 parts of fluorocarbon surfactant, 30 parts of isophorone, and 4 parts of additives ; All the other steps are with embodiment one.

[0024] Wherein, in the step (1), the nano-ceramic resin is composed of nano-scale powder 15, inorganic silicate water and product 30, and water-based silicon acrylic emulsion 8 according to the composition of water-based silicon-acrylic emulsion, inorganic silicate water and product, and nano-scale powder. The order of addition is stirred in the reactor to form; the inorganic silicate water mixture is a sodium silicate water mixture with an average particle size of 80nm and a modulus of 1.8 prepared by the hydrothermal method, and t...

Embodiment 3

[0027] A kind of preparation method of pre-roller coating nano-ceramic coating for metal printing plate, this preparation method comprises following preparation steps:

[0028] (1) Prepare the following components in parts by weight: 75 parts of nano-ceramic resin, 12 parts of curing agent, 3 parts of fumed silica, 2.5 parts of fluorocarbon surfactant, 30 parts of isopropanol, and 4 parts of additives; All the other steps are the same as in Embodiment 1.

[0029] Wherein, in the step (1), the nano-ceramic resin is composed of nano-scale powder 13, inorganic silicate water and product 30, and water-based silicon acrylic emulsion 8 according to the composition of water-based silicon-acrylic emulsion, inorganic silicate water and product, and nano-scale powder. The order of addition is stirred in the reactor to form; the inorganic silicate water mixture is a potassium silicate water mixture with an average particle size of 70nm and a modulus of 1.8 prepared by the hydrothermal me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com