A method and device for producing gasoline blending components

A technology for blending and gasoline, applied in the direction of preparation of ether by addition of unsaturated compounds, chemical industry, climate sustainability, etc., can solve the problems of circulating water consumption, consumption, and need for steam, etc., to achieve oil blending and high quality , The effect of simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for producing gasoline blending components, comprising carrying out isomerization reaction of carbon four components, in which 1-butene, cis-2-butene and trans-2-butene mixtures account for carbon four groups According to 60-80% of the total mass, all reaction products are etherified with methanol, and non-isomerized 1-butene, cis-2-butene and trans-2-butene are separated, and the cycle continues to participate in isomerization liquefaction reaction, other components are liquefied to be gasoline blending components.

[0026] Other specific processes are the same as the prior art.

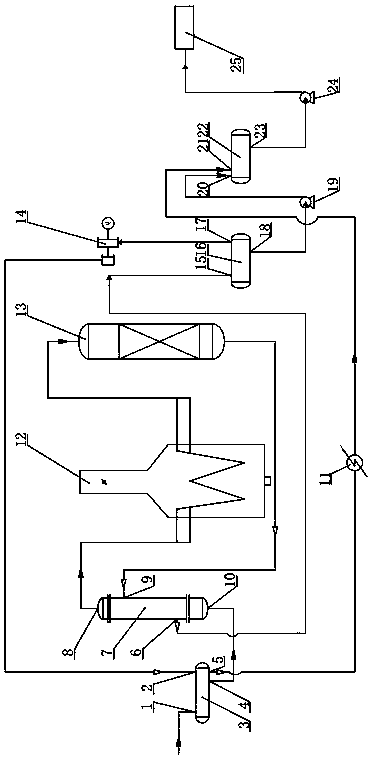

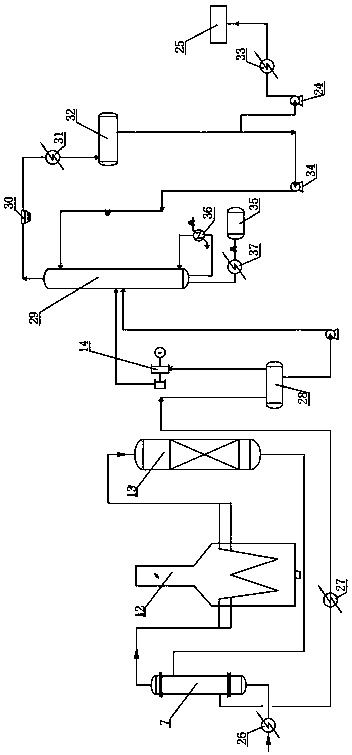

[0027] A device for producing gasoline blending components, see figure 1As shown, it includes a high-efficiency heat exchanger 7, a heating furnace 12, a heterogeneous reactor 13, a compressor 14 and an MTBE device 25. Raw material outlet 8, high-temperature product inlet 9 in the upper part of the high-efficiency heat exchanger, and high-temperature product outlet 6 in the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com