Electric heating furnace

An electric heating furnace and furnace body technology, applied in the field of steel rolling production, can solve the problems of serious environmental pollution, low utilization rate of heat energy, large resource consumption, etc., and achieve the effects of reducing production cost, improving utilization rate of heat energy, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

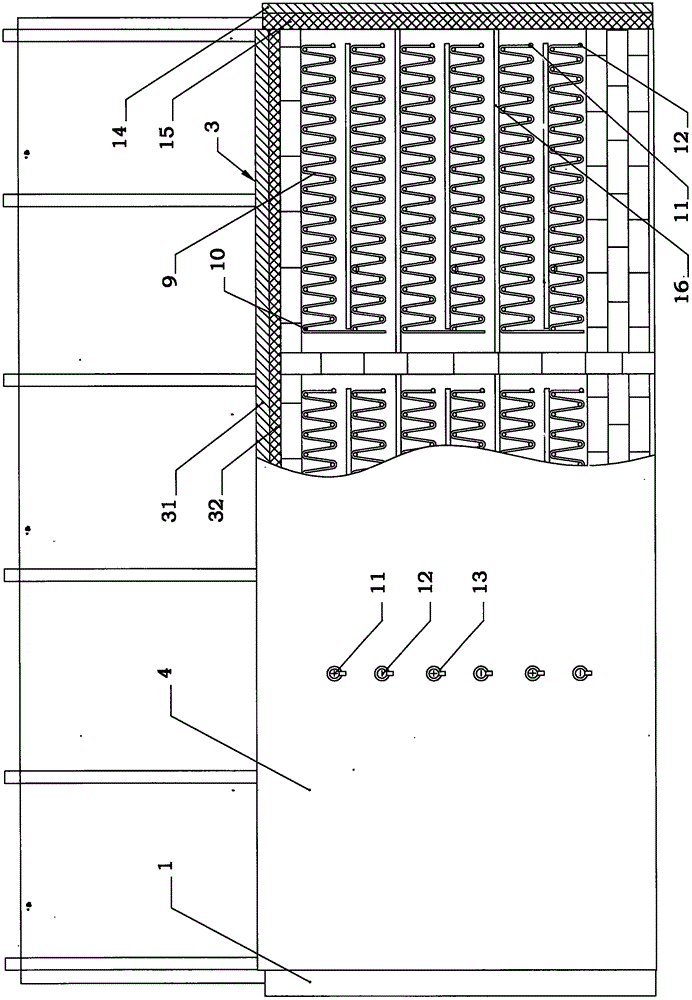

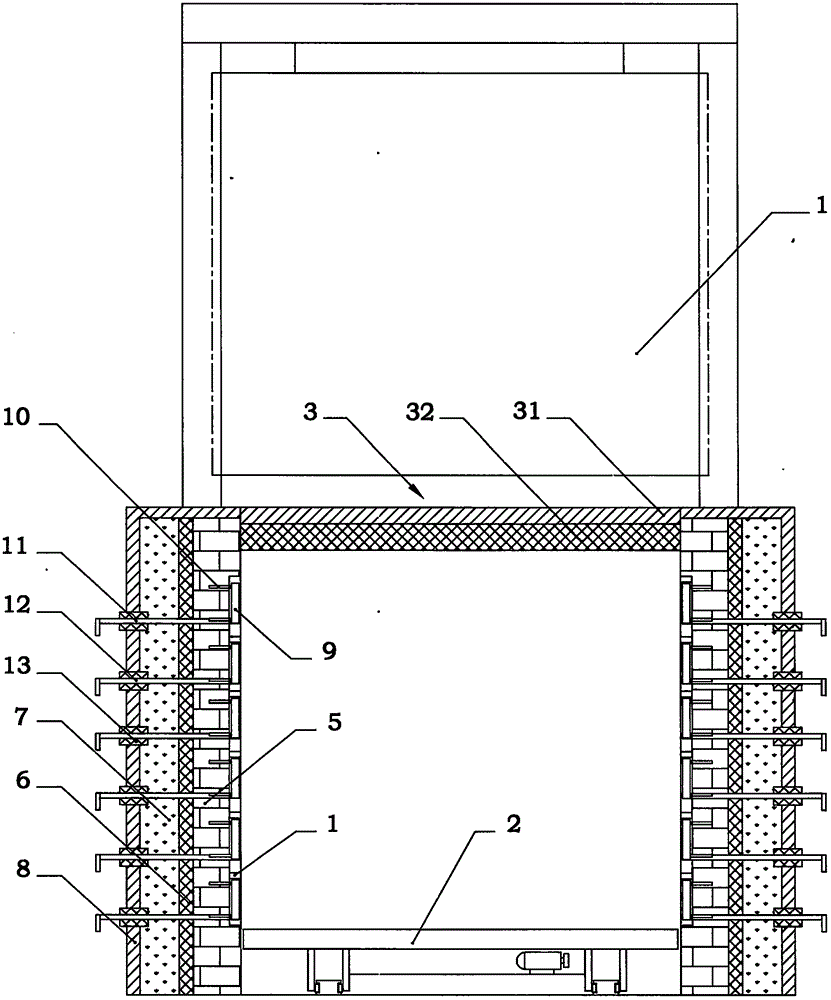

[0017] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0018] like figure 1 , figure 2 As shown, the present invention is an electric heating furnace, comprising a furnace body, a furnace door 1 and a furnace car 2, the two ends of the furnace body are connected and the furnace door 1 is placed at both ends of the furnace body to block the furnace body, and the furnace body Including a furnace roof 3 and furnace walls 4 on both sides; in order to solve technical problems such as low thermal energy utilization rate of existing coal heating furnaces, large resource consumption and serious environmental pollution, the furnace walls 4 are sequentially arranged from the inside to the outside Insulation and heat insulation layer 5, heat insulation fiber layer 6 and / or heat insulation ash layer 7 and metal furnace plate 8; multiple sets of metal heating belts 9 are fixed on the insulation and heat insulation layer 5,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com