Nanometer fiber yarn and preparation method thereof

A nanofiber and yarn technology, applied in fiber processing, filament/thread forming, textile and papermaking, etc., can solve the problem of poor strength of single fiber nanofilament inconvenient for knitting, weaving or weaving, and achieve high strength, Cost reduction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

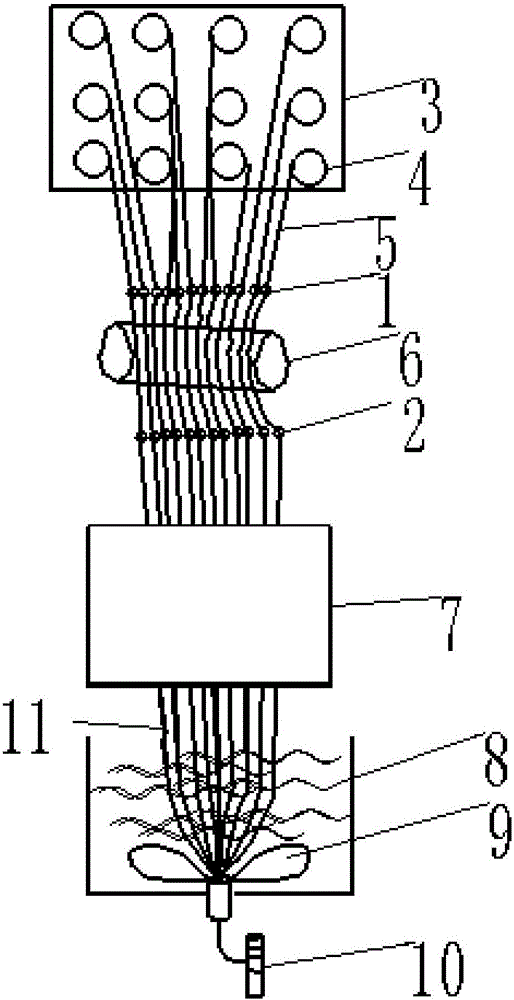

[0036] Embodiment 1 of the present invention is a kind of preparation method of nanofiber yarn, please refer to figure 1 , is a schematic diagram of the preparation of nanofiber yarns, which includes filament unwinding, electrospinning and nanofiber twisting. The preparation method of this nanofiber yarn comprises the following steps:

[0037] (1) Filament group unwinding

[0038] The bobbin 4 with vinylon thin filament 5 is placed on the creel 3, the linear density of the filament 5 is 1.5dtex, the number of bobbins 4 on the creel 3 is 30, and the front of the bobbin 4 is arranged in sequence from near to far. Guide wire hole 1, upper and lower rollers 6 and the second guide wire hole 2, the free end of the filament 5 on the bobbin 4 passes through the first guide wire hole 1, upper and lower rollers 6 and the second guide wire hole 2 successively, and the filament 5 Traction and unwinding by the top and bottom rollers 6 into the electrospinning equipment 7;

[0039] Where...

Embodiment 2

[0051] A kind of preparation method of nanofiber yarn, this preparation method has used the electrospinning equipment used in the embodiment 1 equally, and this preparation method comprises the following steps:

[0052] (1) Filament group unwinding

[0053] The bobbin 4 with vinylon fine filaments is placed on the creel 3, the linear density of the filament 5 is 1.5dtex, the number of bobbins 4 is 100, the filaments are drawn out through the first guide hole 1, and the array of the first guide holes 1 is parallel Arranged on the rollers, the length of the rollers is 40cm, the width of the first guide hole 1 array 2 is 70cm, 5 groups of filaments pass through the upper and lower rollers 6, and the rotation of the upper and lower rollers 6 drives the filament groups to unwind, and the filament unwinding speed is 20m / min.

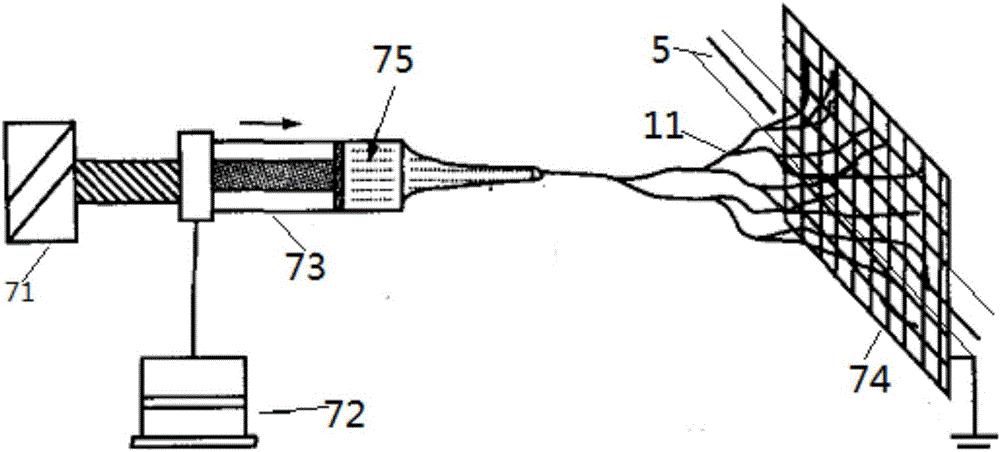

[0054] (2) Electrospinning and spinning

[0055] The receiving plate of the electrospinning equipment is grounded, and the filament group is naturally suspen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Torsion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com