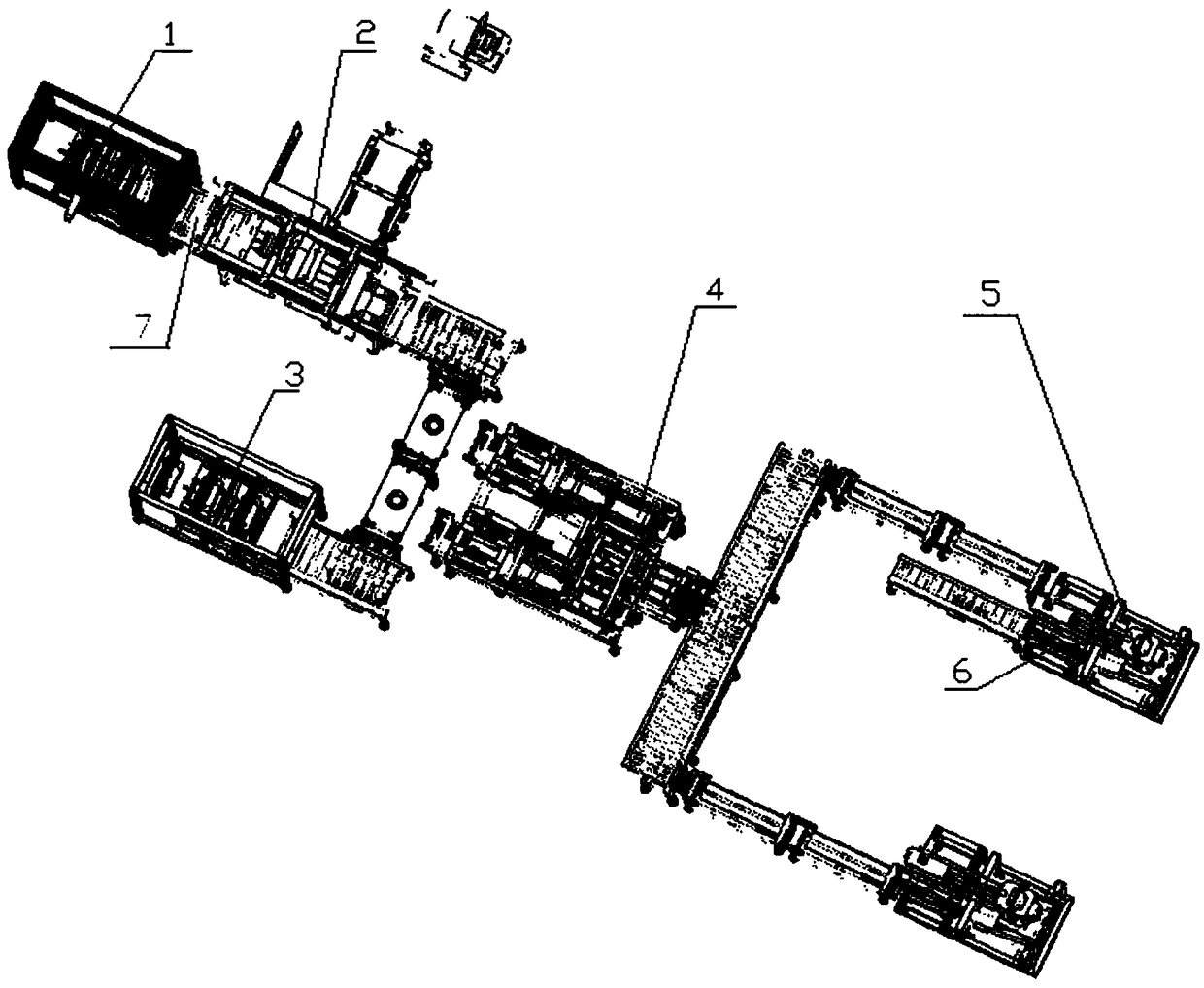

A kind of automatic production equipment and technology of power storage battery

A power battery, automatic production technology, applied in the direction of lead-acid battery construction, lead-acid battery, final product manufacturing, etc., can solve the problems of low degree of automation, harmful to human health, low production efficiency, etc., to improve product consistency, The effect of increasing production capacity and reducing physical injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

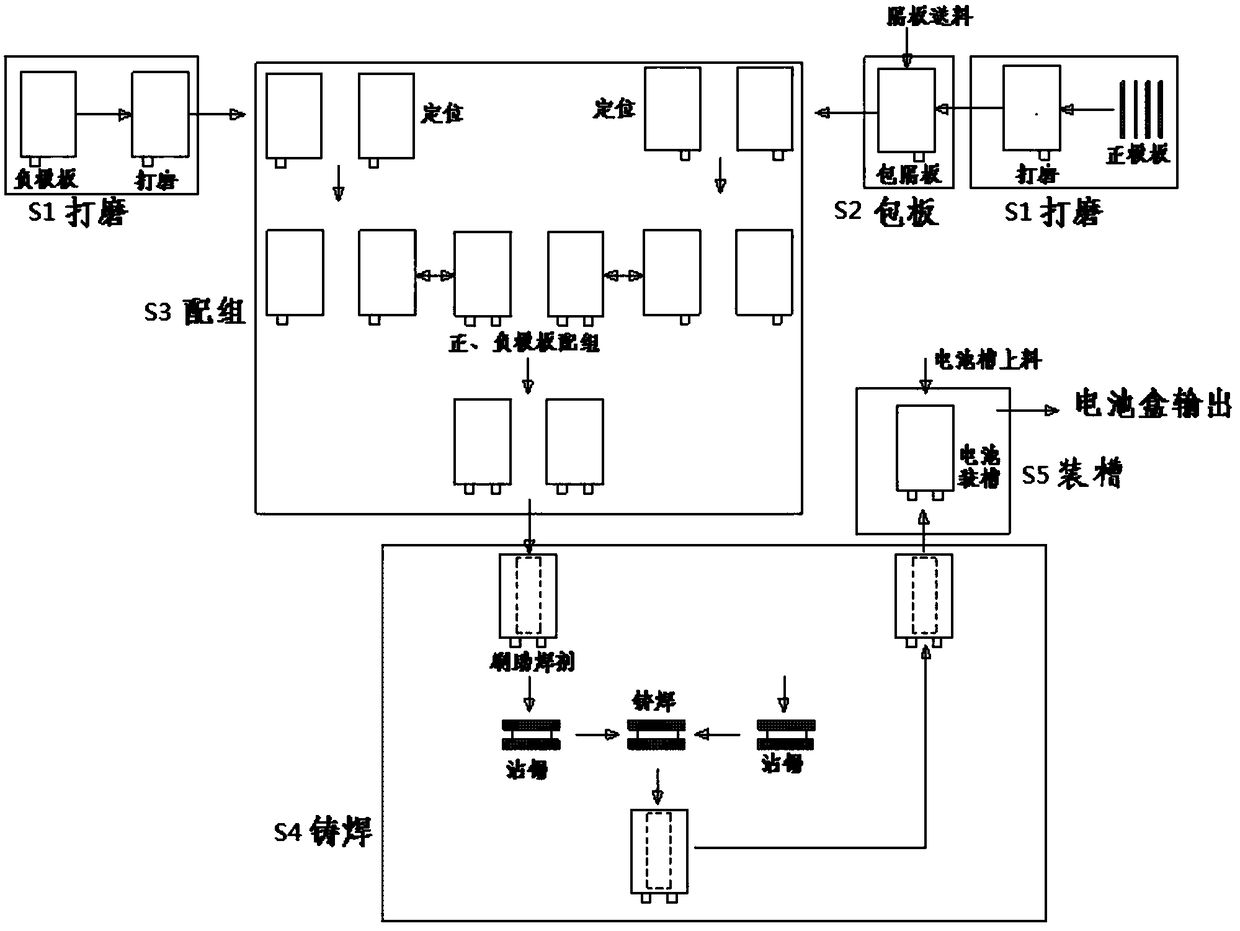

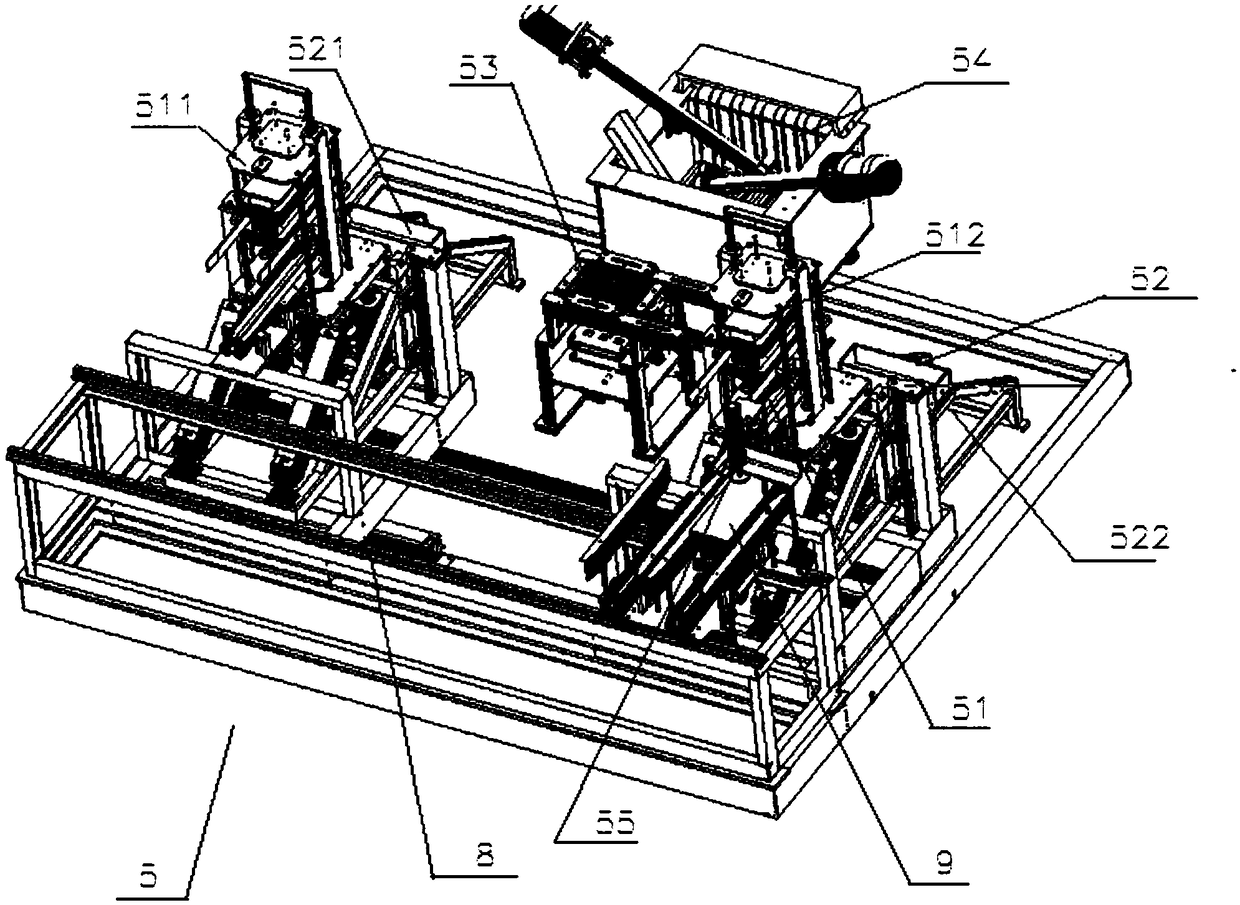

[0060] Taking a traction battery with a capacity of 500Ah as an example, there are 9 negative plates and 8 positive plates. The production and assembly process is as follows:

[0061] S1, respectively polish the five outer surfaces of the positive and negative plate lugs to remove the oxide layer attached to the outer surfaces, and transmit the polished positive plate to the cladding machine 2 through the conveying chain 7;

[0062] S2, plate wrapping machine 2 covers the surface of positive plate with PE separator;

[0063] S3, transfer the positive plate polished and covered with PE separator, and the negative plate to the assembly machine 4 through the transmission equipment, and the assembly machine 4 is arranged and assembled in sequence according to the order of negative plate / positive plate / negative plate to form the plate group, wherein the positive plate tabs are stacked in sequence to form a positive plate tab group, and the negative plate tabs are stacked in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com