Production device for forging stranded welding wires and production technology of production device

A production equipment and forging technology, applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problems of unsuitable cable stranding machine, undisclosed production of multi-strand welding wire, etc., and achieve single wire drawing process Reduced requirements, low difficulty in molten pool control, and reduced single-filament twist length and wire diameter requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

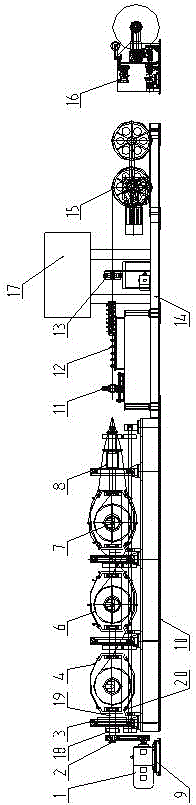

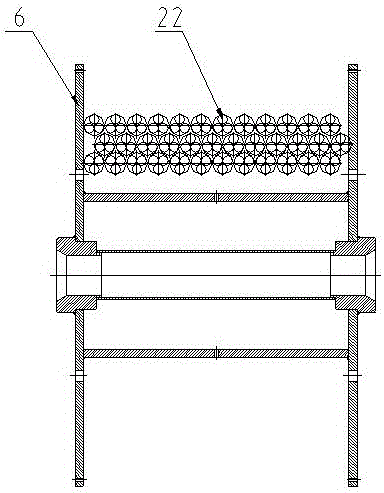

[0052] Such as figure 1 As shown, a production equipment for forging stranded welding wire in this embodiment includes a power base 9, a main machine base 10, a traction base 14 and a wire take-up device 16 arranged in sequence from front to back, and the power base 9 is A power unit 1 is provided, and a plurality of bearing seat devices 3 are sequentially arranged on the main machine base 10 from front to back, and each bearing seat device 3 is provided with a rotating shaft 19, and a mounting bracket 20 passes between two adjacent rotating shafts 19 A cradle device 7 is provided. The cradle device 7 is provided with an I-shaped wheel assembly 6. The upper and lower sides of the cradle device 7 are provided with bow belt devices 4. The power device 1 and the front end of the first rotating shaft 19 pass through The first transmission device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com