Organic liquid fertilizer and preparation method thereof

A technology of organic liquid fertilizer and parts by weight, applied in the directions of organic fertilizers, inorganic fertilizers, liquid fertilizers, etc., can solve the problems of limited adhesion of liquid fertilizers, affecting the use effect of foliar fertilizers, low selenium content, etc. The effect of increasing the intake of selenium and the reasonable proportion of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

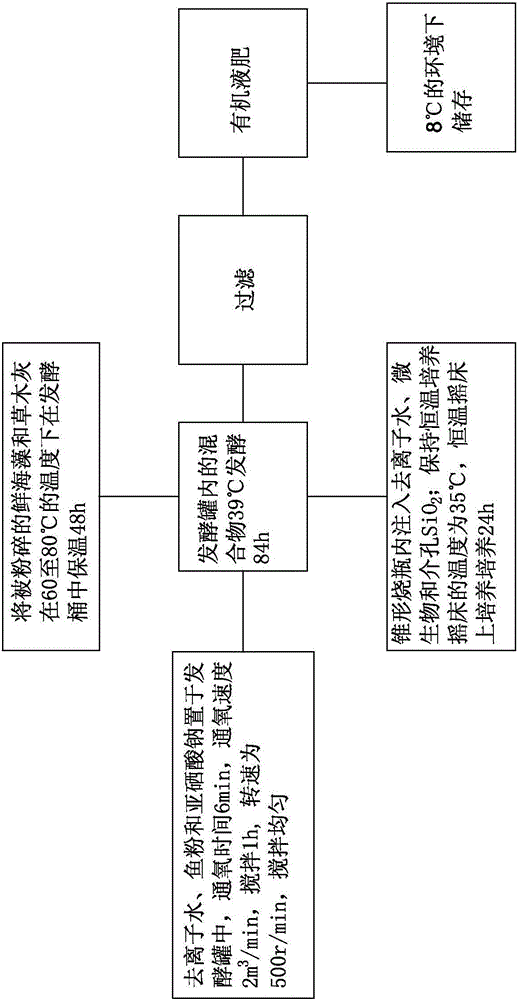

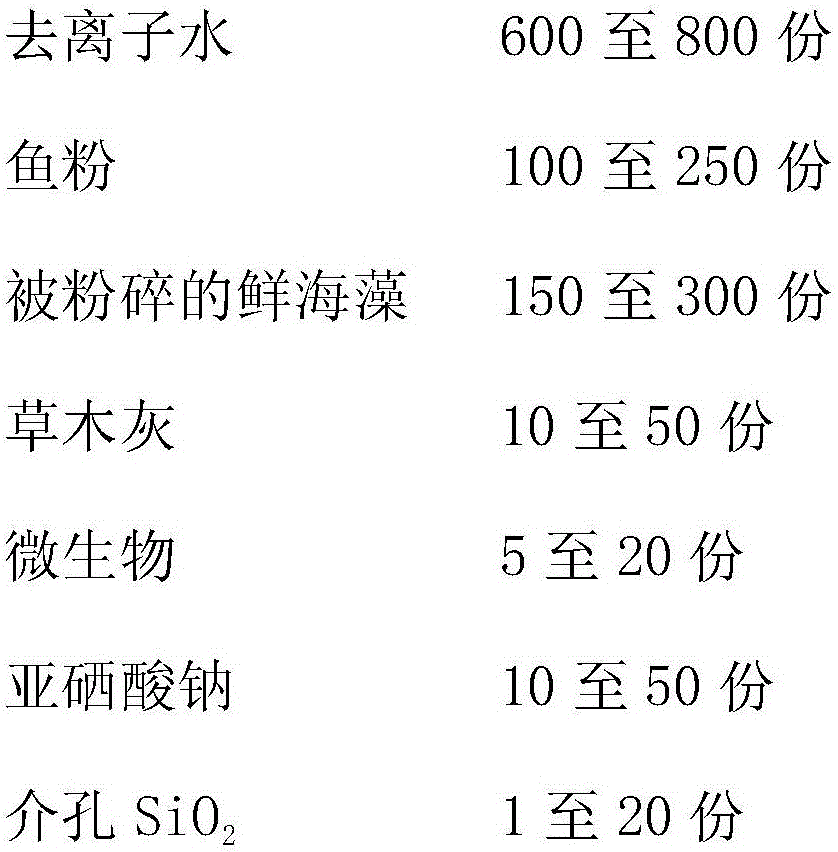

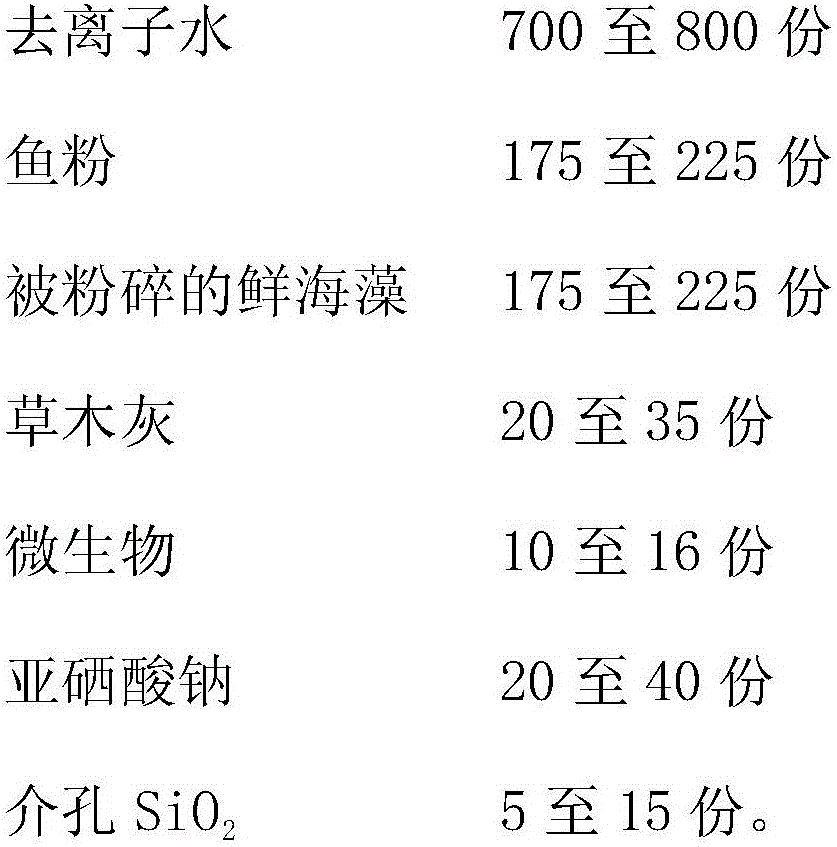

[0030] according to figure 1 The process flow diagram, each component and corresponding parts by weight are as shown in table 1, and concrete process step and parameter are as follows:

[0031] (1) Under normal temperature and pressure, add deionized water, fish meal, and sodium selenite into the fermenter in parts by weight. The time of oxygen circulation is 6 minutes, and the speed of oxygen circulation is 2m. 3 / min, stir for 1h, the speed is 500r / min, stir evenly;

[0032] (2) keeping the pulverized fresh seaweed and plant ash in a fermenter for 48 hours at a temperature of 80°C;

[0033] (3) Inject deionized water into the Erlenmeyer flask, inject microorganisms into it, and then add mesoporous SiO2 into the Erlenmeyer flask 2 ; Keep the temperature of the constant temperature culture shaker at 35 °C, and the microorganisms and mesoporous SiO 2 The Erlenmeyer flask was placed on a constant temperature culture shaker and cultivated for 24h;

[0034] (4) Pour the mixed ...

Embodiment 2

[0037] according to figure 1 The process flow diagram, each component and corresponding parts by weight are as shown in table 1.

Embodiment 3

[0039] according to figure 1 The process flow diagram, each component and corresponding parts by weight are as shown in table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com